Method and apparatus for preparing water-soluble CdTe nanocrystalline

A nanocrystalline, water-soluble technology, applied in the field of preparation of semiconductor nanomaterials, achieves the effects of improved efficiency, optimized reaction conditions, and accelerated reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

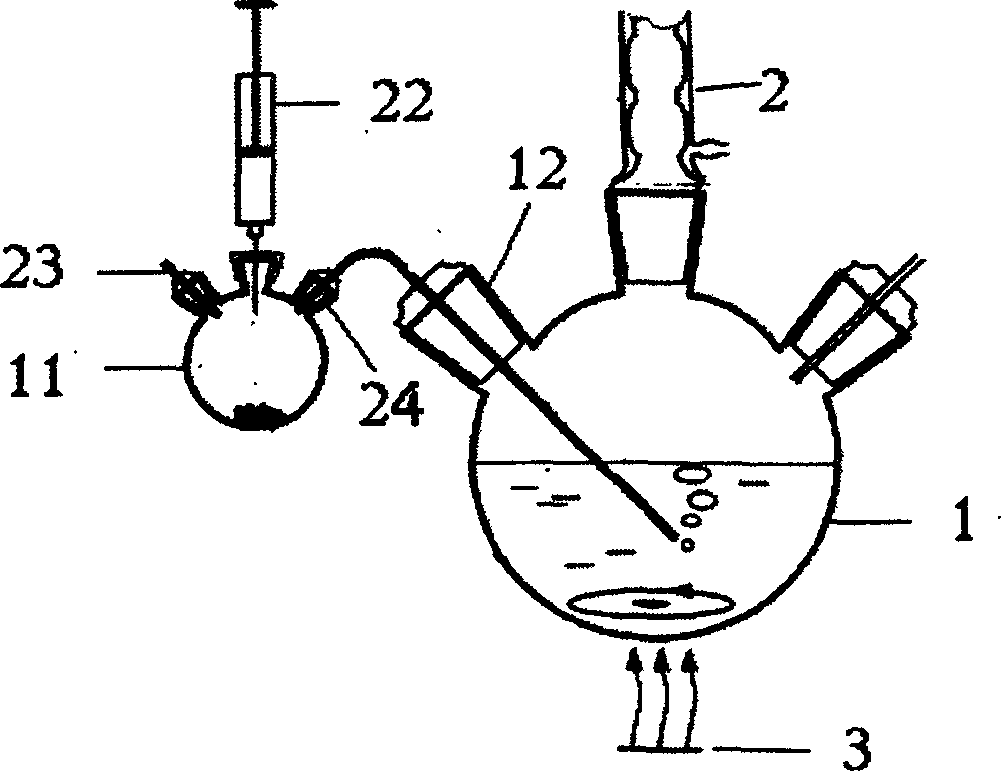

Image

Examples

Embodiment 1

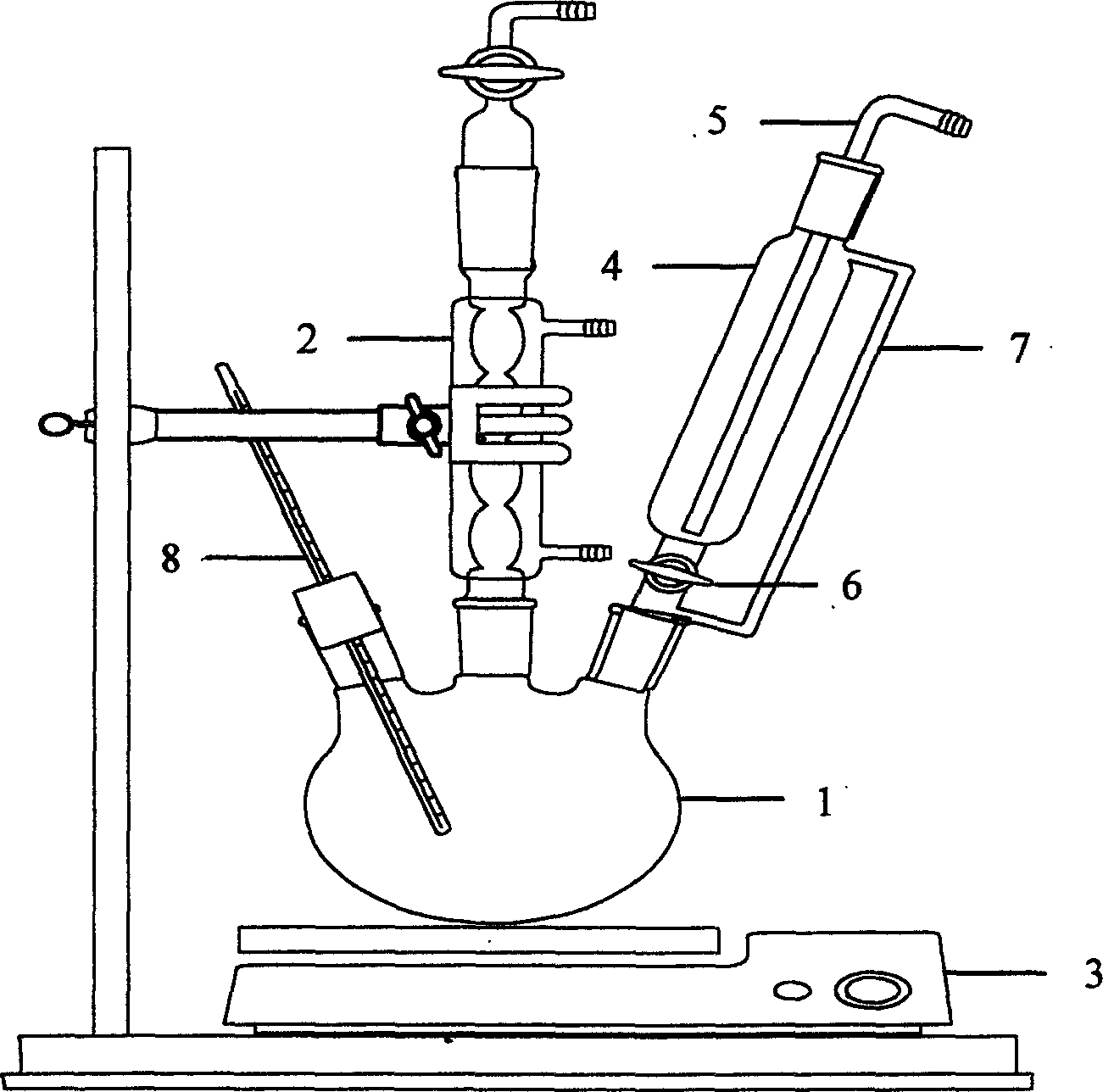

[0018] Embodiment 1: device of the present invention

[0019] refer to figure 2 The device for preparing water-soluble CdTe nanocrystals of the present invention is specifically described.

[0020] figure 2 Among them, 1 is a three-necked bottle, 2 is a reflux condenser installed on the middle neck of the three-necked bottle 1, and 3 is a heating device below the three-necked bottle 1, which can be a magnetic stirring heater. Three-neck bottle 1 is not only the source of tellurium, but also the reducing agent NaBH for tellurium powder 4 The reduced container is also used as a heated reflux container.

[0021] An airtight constant pressure funnel 4 is installed on a side neck of the three-necked bottle 1 to prepare the cadmium-mercapto compound; the constant pressure funnel 4 is equipped with a nitrogen pipe 5; the structure of the constant pressure funnel 4 also includes the discharge below Valve 6 and the connecting pipe 7 on the side, one end of the connecting pipe 7 l...

Embodiment 2

[0023] Embodiment 2: the reaction process of ice-water bath

[0024] Weigh 0.042g Cd(ClO 4 ) 2 ·6H 2 O as the cadmium source was dissolved in 50 mL of high-purity water, 21 uL of thioglycolic acid was added, mixed evenly, the pH value was adjusted to 10 with 1M NaOH, and placed in the constant pressure funnel 4. In the three-necked bottle 1, add 6.38mg tellurium powder as raw material, 5mg NaBH 4 as a reducing agent. The system was evacuated and nitrogen gas was passed. Place the three-necked bottle 1 in an ice-water bath, and add a certain amount of water to the three-necked bottle 1 . After the tellurium powder was reacted for 8 hours, the discharge valve 6 was opened, and the cadmium-mercapto complex in the constant pressure funnel 4 was added to the three-necked bottle 1 . The system was heated and held at reflux.

[0025] By controlling the reflow time, CdTe nanocrystals with negative charge and carboxylate on the surface can be obtained with different luminescence...

Embodiment 3

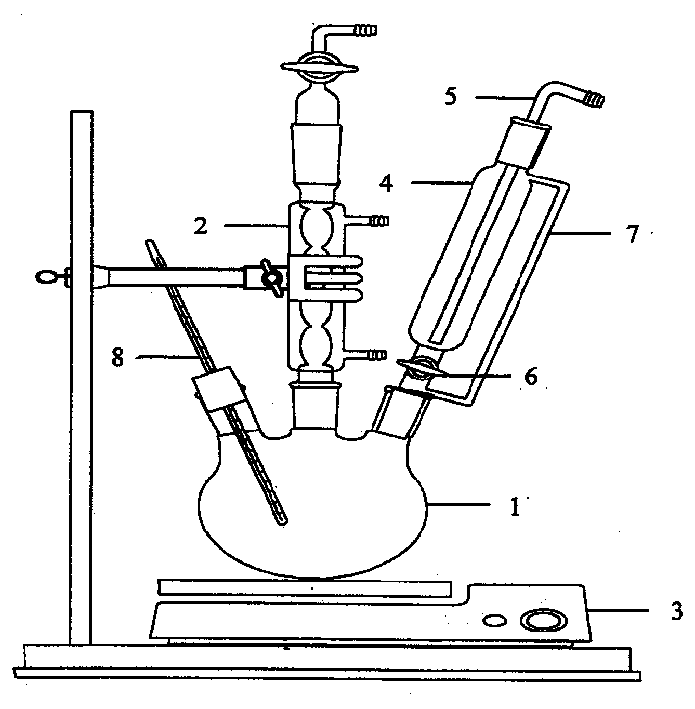

[0026] Embodiment 3: NaHTe generates under the condition of heating

[0027] The reaction apparatus described in Example 1 was used.

[0028] Weigh 0.042g Cd(ClO 4 ) 2 ·6H 2 O, dissolved in 50mL of high-purity water, added 21uL of mercaptoacetic acid, mixed evenly, adjusted the pH value to 10 with 1M NaOH, and placed in constant pressure funnel 4. In the three-necked bottle 1, add 6.38mg tellurium powder, 5mg NaBH4. The system was evacuated and nitrogen gas was passed. A certain amount of water is added into the three-necked bottle 1 to make the tellurium powder react under the condition of 30-80° C., and the reaction of forming NaHTe is completed within 10-40 minutes. Add the cadmium-mercapto compound in the constant pressure funnel 4 into the three-necked bottle 1 . The system was heated and held at reflux.

[0029] CdTe nanocrystals with negative charges and carboxylate groups on the surface with different luminescence can be obtained by controlling the reflow time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com