Wheat plumule protein hydrolysate and its prepn process and use

A technology of wheat germ protein and wheat germ, which is applied in the field of development and utilization of vegetable protein

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

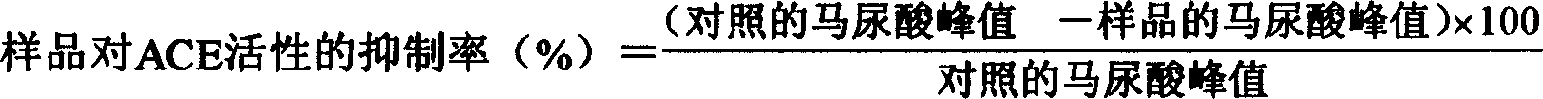

Image

Examples

Embodiment 1

[0015] Defatted wheat germ (34.23% protein content) was pulverized by a pulverizer and passed through a 100-mesh sieve. Weighed 50 g of wheat germ powder and added 500 mL of distilled water, weighed 5 g of NaCl, dissolved it in a small amount of water and added it to the above solution, adjusted the pH value to 9.0, and used a magnetic Stir with the agitator for 30 minutes, then centrifuge at 5000r / min for 10 minutes, take the supernatant, and adjust the pH value to 4.0. Desalted and dried to obtain wheat germ protein powder for protease treatment.

[0016] Weigh the above 5g wheat germ protein powder, add 125ml of distilled water to dissolve, add protease according to the ratio of 24AU / kg, adjust the pH value to the optimum value of enzyme action with sodium hydroxide and hydrochloric acid (see Table 1), keep a fixed temperature (see Table 1) Under hydrolysis for 7h. During the hydrolysis process, the pH value is constantly adjusted to keep its value at a constant value. Af...

Embodiment 2

[0024] Weigh 2g of the wheat germ protein powder prepared in Example 1, add 90ml of distilled water to dissolve, add 20mg of trypsin, adjust the pH value to 8, heat to 50°C, and keep warm for 6h for hydrolysis. After the hydrolysis is completed, heat and boil for 15 minutes, then centrifuge at 10,000 r / min for 10 minutes, and take the supernatant.

[0025] Subsequently, through ultrafiltration (molecular weight cut-off is 5000Da), then adjust to pH value 3-4, add a certain proportion of activated carbon, stir, and vacuum filter to complete decolorization. Further step-by-step purification was carried out by D61 macroporous strongly acidic cation exchange, SePH value adex G-15 column chromatography, and RP-HPLC to obtain two single components with high ACE inhibitory activity, and their structures were identified by LC / MS. The results show that the two components are tripeptide Ala-Met-Tyr and dipeptide Val-Trp respectively, and their IC50s are 0.059mg / mL and 0.063mg / mL, and IC...

Embodiment 3

[0027] Weigh 500g of the wheat germ protein powder prepared in Example 1, add 6000ml of distilled water to dissolve, add trypsin at a ratio of 1.5%, adjust the pH value to 9, heat to 50°C, keep warm for 5 hours, and heat to inactivate the enzyme; Add alkaline protease at a certain ratio, adjust the pH value to 10, heat to 45°C, keep the hydrolysis for 6 hours, and heat to inactivate the enzyme. After the hydrolysis is completed, heat and boil for 15 minutes, then centrifuge at 10,000 r / min for 10 minutes, and take the supernatant. Ultrafilter the supernatant, take the filtrate, add 0.2% activated carbon, stir on a magnetic stirrer for 10 min, and vacuum filter to complete decolorization. The filtrate was centrifuged at 5000r / min for 10min to remove the precipitate, and the supernatant was obtained, which was lyophilized and formulated into oral liquid, tablet, injection and capsule for animal experiments.

[0028] The rats used in the experiment are spontaneously hypertensive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com