Water metal anticorrosive coating

A metal anti-corrosion and coating technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the application limitations of metal anti-corrosion coatings, environmental pollution and other problems, and achieve excellent anti-corrosion performance, convenient use, and excellent film performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

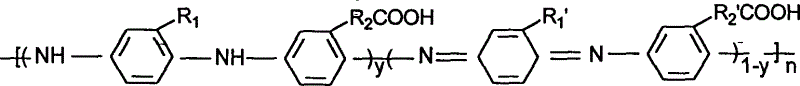

[0023] Add 1.0g of aniline copolymer (1) to a mixture of 20ml of N-methylpyrrolidone (NMP) and 10ml of diethylenetriamine, start stirring, react at 140°C for 10h under reflux, and distill off excess NMP and diethylenetriamine, and the resulting condensate was formulated into an aqueous solution with an aniline copolymer content of 20%. The structure of aniline copolymer (1) is as follows:

[0024]

[0025] In the formula: y=0-1, n=100-200.

[0026] Get 15g of epoxy water emulsion (solid content is 38.5%), add 4g of curing agent aqueous solution prepared above, stir evenly, leave standstill after no foam, brush this coating on the steel plate surface through degreasing and derusting treatment with brush , the dry film thickness is controlled at about 100 μm, and cured at room temperature for 48 hours.

Embodiment 2

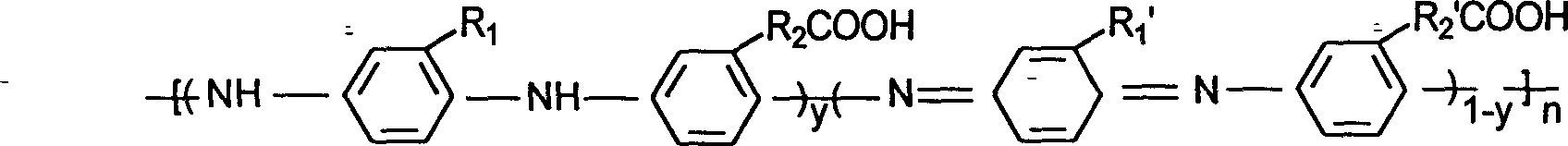

[0028] Add 1.0g of aniline copolymer (2) to a mixture of 30ml of N-N dimethylformamide (DMF) and 10ml of diethylenetriamine, start stirring, react at 140°C under reflux for 10h, and distill under reduced pressure. Remove excess DMF and diethylenetriamine, and prepare the obtained condensate into an aqueous solution with an aniline copolymer content of 20%.

[0029] The structure of aniline copolymer (2) is as follows:

[0030]

[0031] In the formula: y=0-1, n=5-50.

[0032] Get 15g of epoxy water emulsion (solid content is 38.5%), add 4g of curing agent aqueous solution prepared above, stir evenly, leave standstill after no foam, brush this coating on the steel plate surface through degreasing and derusting treatment with brush , the dry film thickness is controlled at about 100 μm, and cured at room temperature for 48 hours.

Embodiment 3

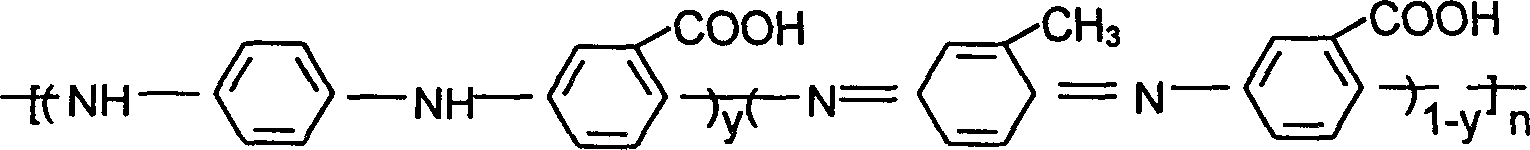

[0034] Add 1.0g of aniline copolymer (3) to a mixture of 30ml of dimethyl sulfoxide (DMSO) and 10ml of diethylenetriamine, start stirring, react at 140°C under reflux for 10h, and distill off excess DMSO and diethylenetriamine, and the resulting condensate was formulated into an aqueous solution with an aniline copolymer content of 20%.

[0035] The structure of aniline copolymer (3) is as follows:

[0036]

[0037] In the formula: y=0-1, n=5-50.

[0038] Get 15g of epoxy water emulsion (solid content is 38.5%), add 4g of curing agent aqueous solution prepared above, stir evenly, leave standstill after no foam, brush this coating on the steel plate surface through degreasing and derusting treatment with brush , the dry film thickness is controlled at about 100 μm, and cured at room temperature for 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com