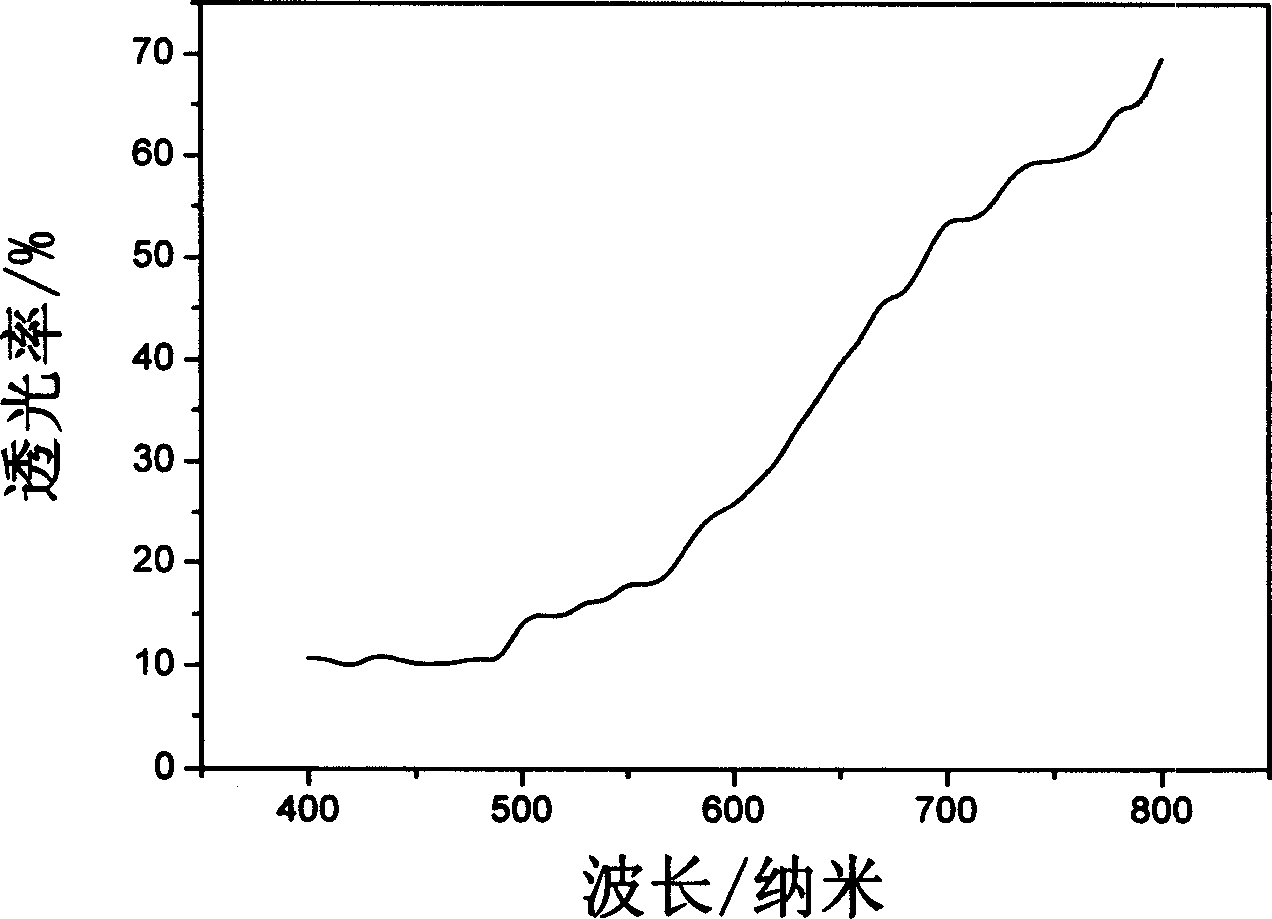

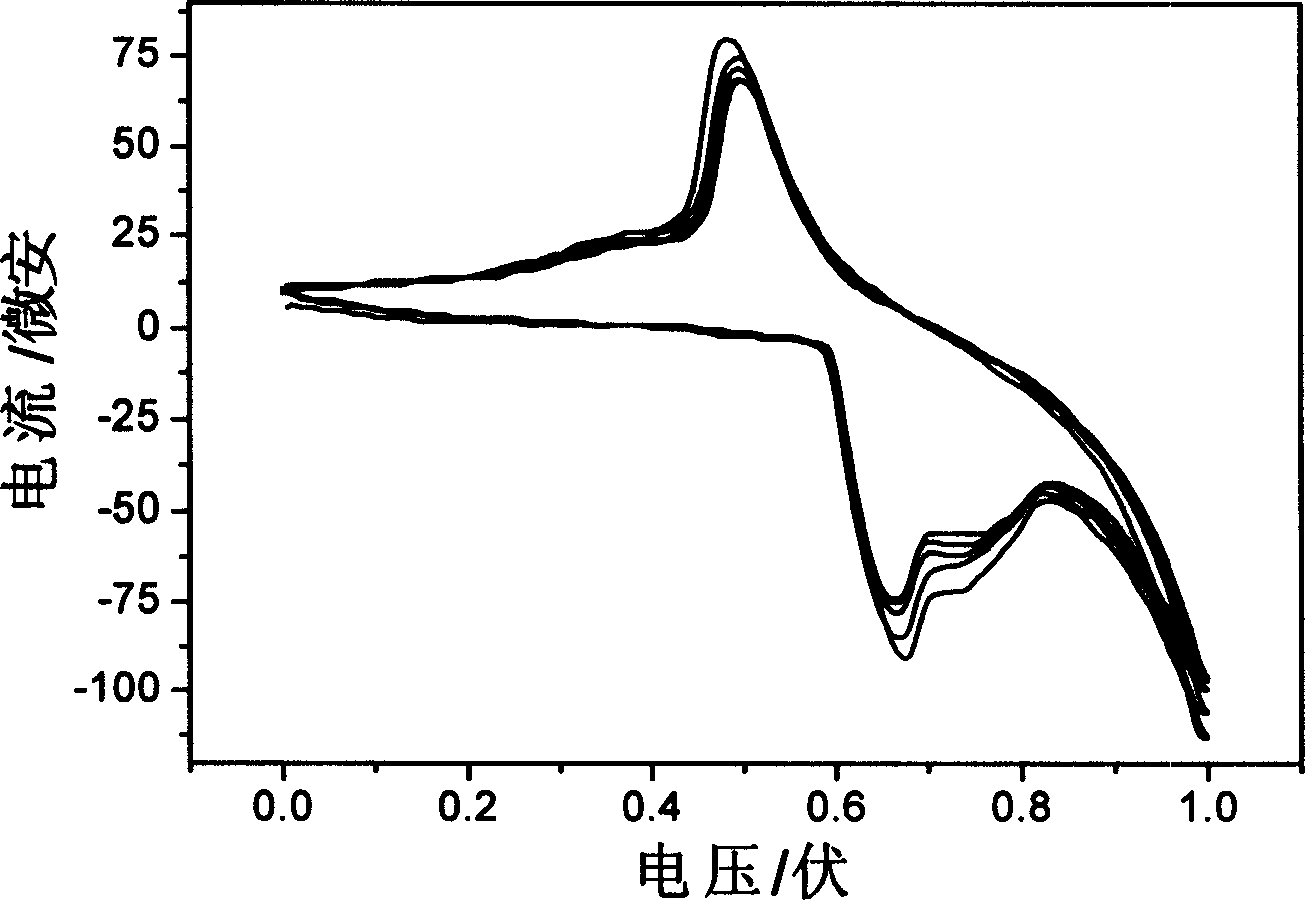

Nickel oxide nano electrochromism film and preparing method thereof

An electrochromic and nickel oxide technology, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of many control steps, complicated and complex preparation process of nickel oxide electrochromic film, and achieve good compactness and stability Good performance and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] (1), the preparation of nickel sol

[0028] 1. Mix 48ml of absolute ethanol and 12ml of butanol to obtain an organic solvent, and add 1.2g of NiCl under stirring 2 Reflux for half an hour when the temperature is raised to 76° C., add 1.2 g of distilled water, and continue to reflux for 1 hour to obtain nickel sol.

[0029] 2. Take 40ml absolute ethanol and 20ml amyl alcohol and mix to obtain an organic solvent, add 1.8g Ni(NO 3 ) 2 Reflux for half an hour when the temperature is raised to 80° C., add 0.36 g of citric acid and 1.8 g of distilled water, and continue to reflux for 1.5 hours to obtain nickel sol.

[0030] 3. Mix 35ml of absolute ethanol and 25ml of hexanol to obtain an organic solvent, add 2.4g of NiSO under stirring 4 Reflux for half an hour when the temperature is raised to 82°C, add 0.48g of glutaric acid and 2.4g of distilled water, and continue to reflux for 2 hours to obtain nickel sol.

[0031] (two), the preparation of nickel oxide thin film

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com