Polyaniline/carbon nano tube hybrid super capacitor

A carbon nanotube, supercapacitor technology, applied in hybrid capacitor electrodes, capacitors, electrolytic capacitors, etc., to achieve the effect of long cycle life, excellent performance and high specific energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Mix the composite material of polyaniline and carbon nanotubes (containing 10% carbon nanotubes) and acetylene black evenly, add the acetone solution of PVDF-HFP dropwise, and apply it on the nickel foam, press it, and dry it in vacuum to obtain polyaniline electrode. Wherein: polyaniline and carbon nanotube composite material / acetylene black / PVDF-HFP=0.85 / 0.1 / 0.05 (mass ratio).

[0024] Mix carbon nanotubes and acetylene black evenly, add PVDF-HFP (vinylidene fluoride-hexafluoropropylene copolymer) acetone solution dropwise, and apply it on nickel foam, press and dry in vacuum to obtain carbon nanotube electrodes. Wherein: carbon nanotube / acetylene black / PVDF-HFP=0.85 / 0.1 / 0.05 (mass ratio).

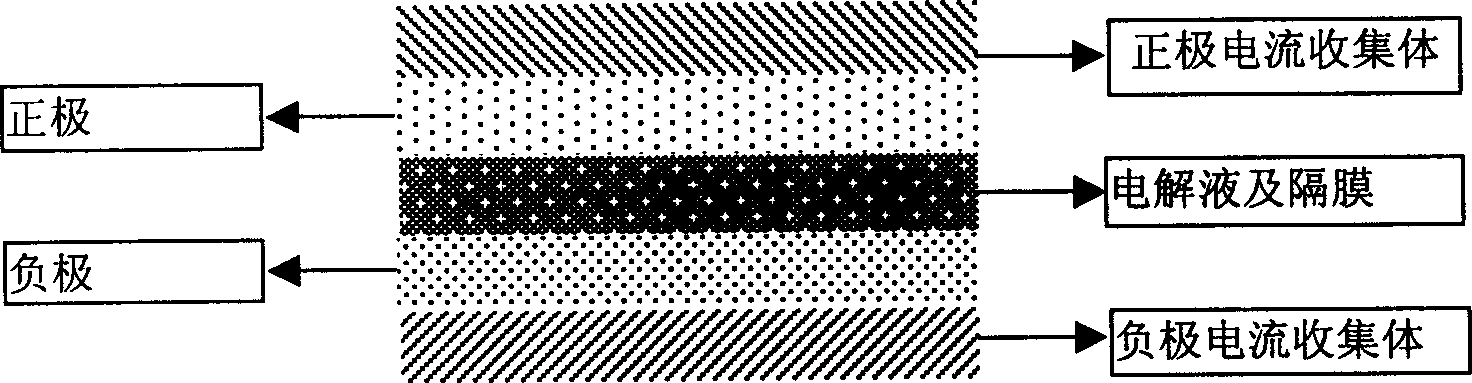

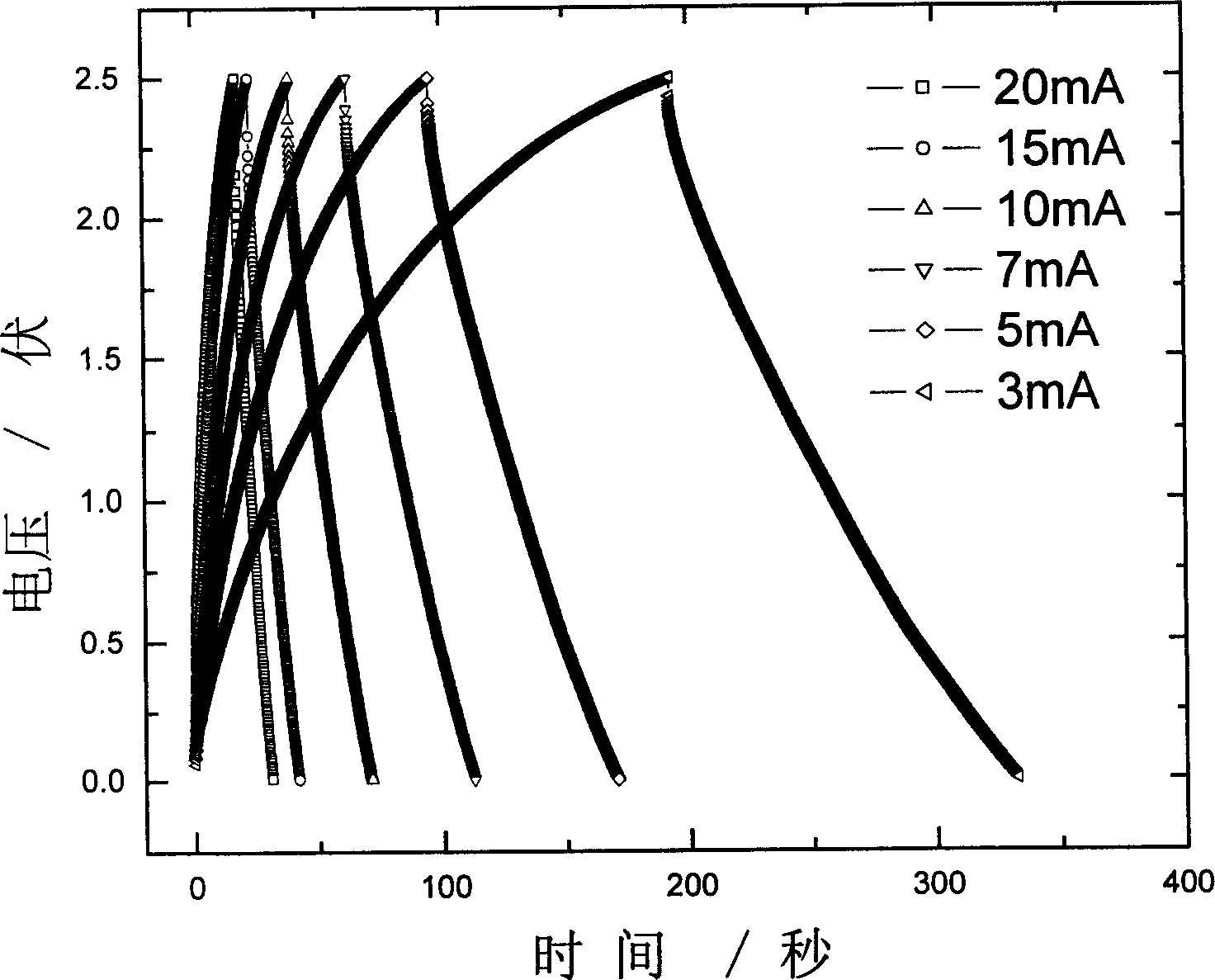

[0025] The above-mentioned polyaniline electrode and carbon nanotube electrode were used as positive and negative electrodes respectively, nickel foam was used as positive and negative electrode current collectors, and 1mol / L LiPF 6 The EC / DEC (ethylene carbonate / butylene carbon...

Embodiment 2

[0027] Mix polyaniline and acetylene black evenly, add PVDF-HFP acetone solution dropwise, and apply it on nickel foam, press it, and dry it in vacuum to obtain polyaniline electrode. Wherein: polyaniline / acetylene black / PVDF-HFP=0.85 / 0.1 / 0.05 (mass ratio), wherein polyaniline is 8.5mg.

[0028] Mix carbon nanotubes and acetylene black evenly, add PVDF-HFP acetone solution dropwise, and spread on nickel foam, press and dry in vacuum to obtain carbon nanotube electrodes. Wherein: carbon nanotube / acetylene black / PVDF-HFP=0.85 / 0.1 / 0.05 (mass ratio), wherein 17mg of carbon nanotube.

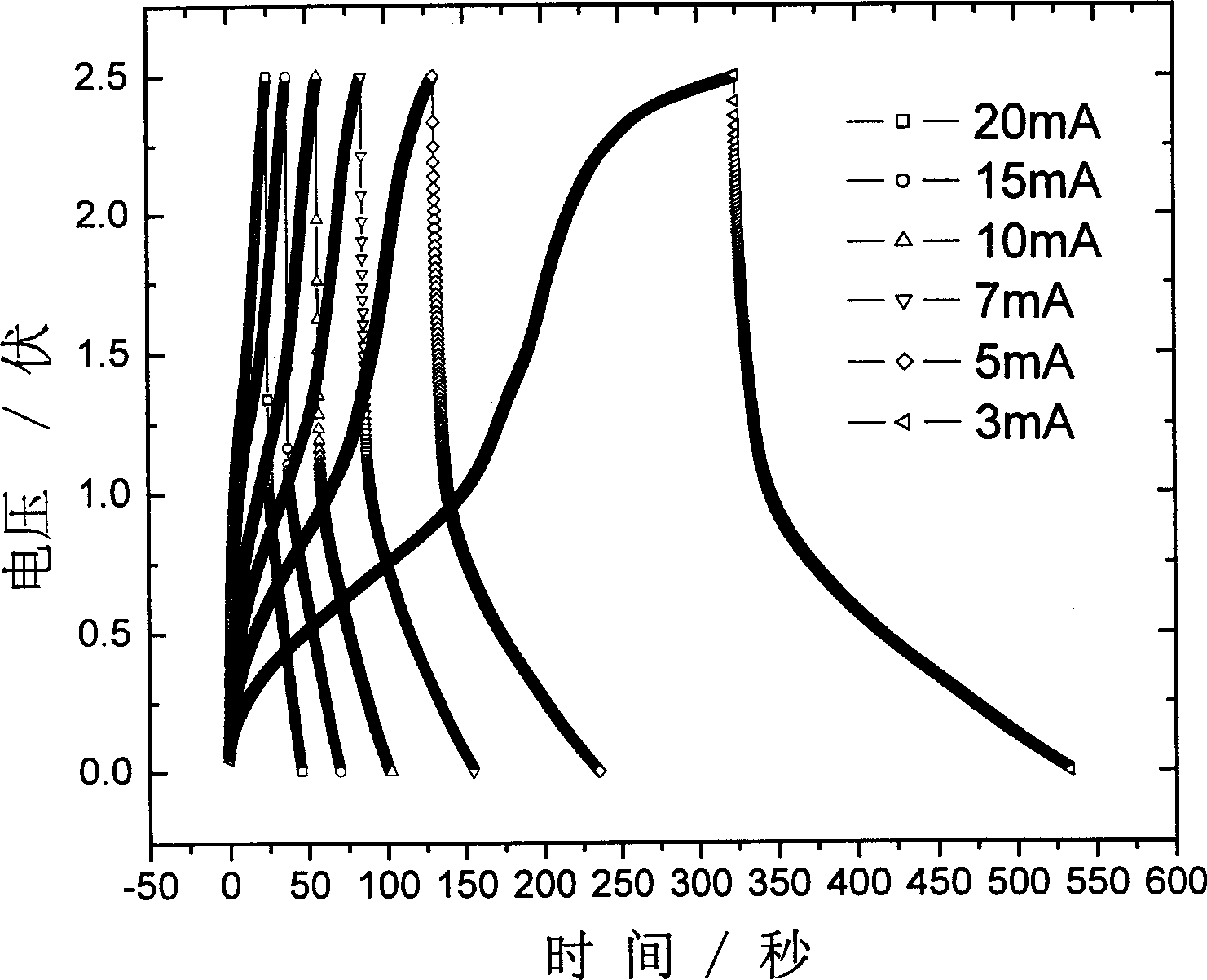

[0029] The above-mentioned polyaniline electrode and carbon nanotube electrode were used as positive and negative electrodes respectively, nickel foam was used as positive and negative electrode current collectors, and 1mol / L LiPF 6 EC / DEC (ethylene carbonate / butylene carbonate=1 volume ratio) solution is used as electrolyte, and Celgard2300 microporous membrane is used as diaphragm. In an atmospher...

Embodiment 3

[0031] Mix polyaniline and acetylene black evenly, add PVDF-HFP acetone solution dropwise, and apply it on nickel foam, press it, and dry it in vacuum to obtain polyaniline electrode. Wherein: polyaniline / acetylene black / PVDF-HFP=0.85 / 0.1 / 0.05 (mass ratio), wherein polyaniline is 8.5 mg.

[0032] Mix carbon nanotubes, activated carbon and acetylene black evenly, add PVDF-HFP acetone solution dropwise, and apply it on nickel foam, press it, and dry it in vacuum to obtain a carbon nanotube electrode. Wherein: carbon nanotube / activated carbon / acetylene black / PVDF-HFP=0.75 / 0.1 / 0.1 / 0.05 (mass ratio), wherein carbon nanotube and activated carbon are 25.5mg.

[0033] The above-mentioned polyaniline electrode and carbon nanotube electrode were used as positive and negative electrodes respectively, nickel foam was used as positive and negative electrode current collectors, and 1mol / L LiPF 6 EC / DEC (ethylene carbonate / butylene carbonate=1 volume ratio) solution is used as electrolyte, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific energy | aaaaa | aaaaa |

| Specific energy | aaaaa | aaaaa |

| Specific energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com