Process for preparing gradient porous ceramic filter element

A technology of ceramic filtration and gradient holes, applied in ceramic products, filtration separation, separation methods, etc., can solve the problems of affecting the filtration efficiency of products, unstable product performance, and affecting bonding strength, etc., to achieve high thermal shock resistance and produce finished products The effect of high rate and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

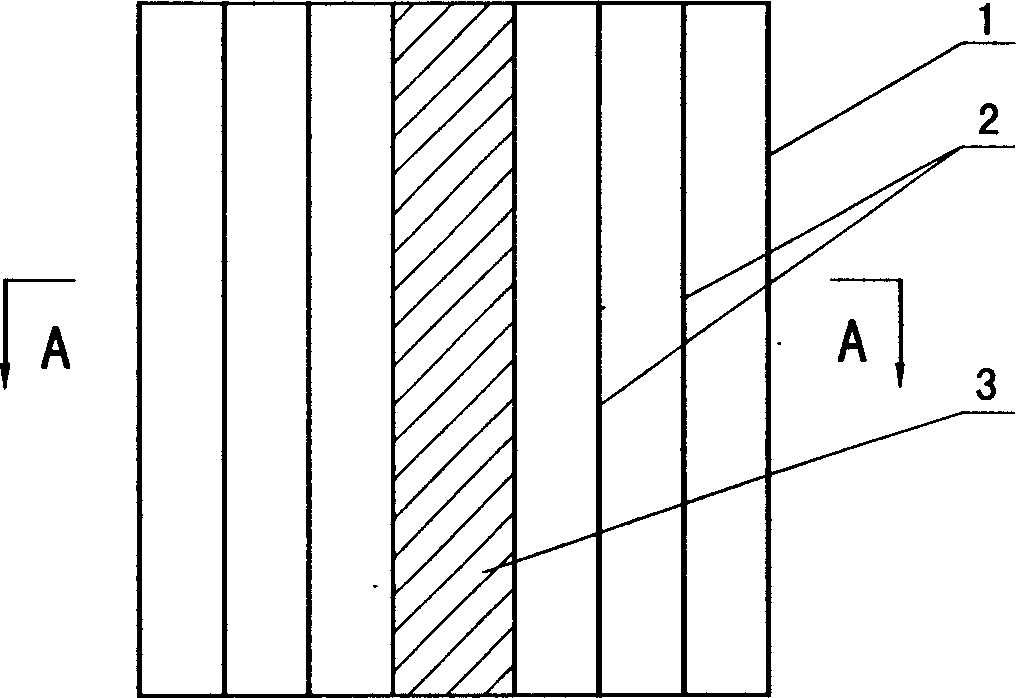

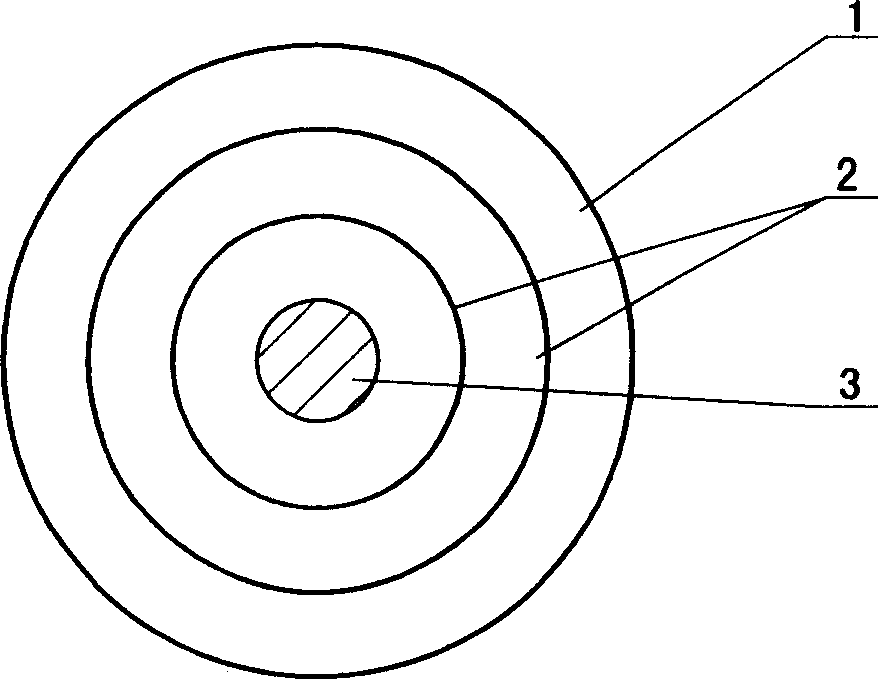

[0023] The preparation method of the gradient hole ceramic filter element of the present invention includes ceramic powder treatment, preparation of blanks, molding and firing processes, taking alumina ceramic powders with a particle size of 45 μm, 20 μm, and 3 μm as examples, the preparation method is as follows :

[0024] ①Ceramic powder treatment process:

[0025] Aggregate particles I: 60% alumina (45μm), 40% high temperature binder solution;

[0026] Aggregate particle II: alumina (20μm) 65%, high temperature binder solution: 35%;

[0027] Aggregate particle III: alumina (3μm) 70%, high temperature binder solution: 30%.

[0028] The mass percentage of the high-temperature binder solution is composed of: 10-30% of alumina sol, 30-10% of aluminum phosphate sol, 20-30% of sodium silicate (water glass) solution, and 0.05-1% polyvinyl alcohol The solution is 20-15%, and the concentration is 0.05-1% of the cellulose solution 20-15%.

[0029] In the ceramic powder treatment ...

Embodiment 2

[0039] Taking alumina ceramic powder with a particle size of 45 μm and 3 μm and silicon carbide ceramic powder with a particle size of 20 μm as examples, the preparation method is as follows:

[0040] ①Ceramic powder treatment process:

[0041] Aggregate particle I: alumina (45μm) 60%, high temperature binder solution: 40%;

[0042] Aggregate particles II: silicon carbide (20μm) 67%, high temperature binder solution: 33%;

[0043] Aggregate particle III: alumina (3μm) 70%, high temperature binder solution: 30%.

[0044] The ceramic powder treatment process is the same as in Example 1.

[0045] ② Billet preparation process: The mass composition of the billet is: processed alumina aggregate particles I, III and silicon carbide aggregate particles II are: 80-95%, molding binder 8-1%, pore-enhancing agent 7-3 %, water 5-1%. The composition and preparation of the molding binder and the pore-enhancing agent are the same as in Example 1, and three blanks I, II, and III are obtain...

Embodiment 3

[0051] Taking alumina ceramic powder with a particle size of 5 μm as an example, the preparation process is as follows:

[0052] ①Ceramic powder treatment process: alumina (5μm) 70%, high temperature binder solution: 30%. The ceramic powder treatment process is the same as in Example 1 to obtain the required aggregate particles.

[0053] ②Bill preparation process: The mass percentage of the blank is composed of: 80-95% of aggregate particles, 8-1% of forming binder, 7-3% of pore-enhancing agent, and 5-1% of water. Wherein: the composition and preparation of forming binder, pore-enhancing agent, and water are the same as in Example 1.

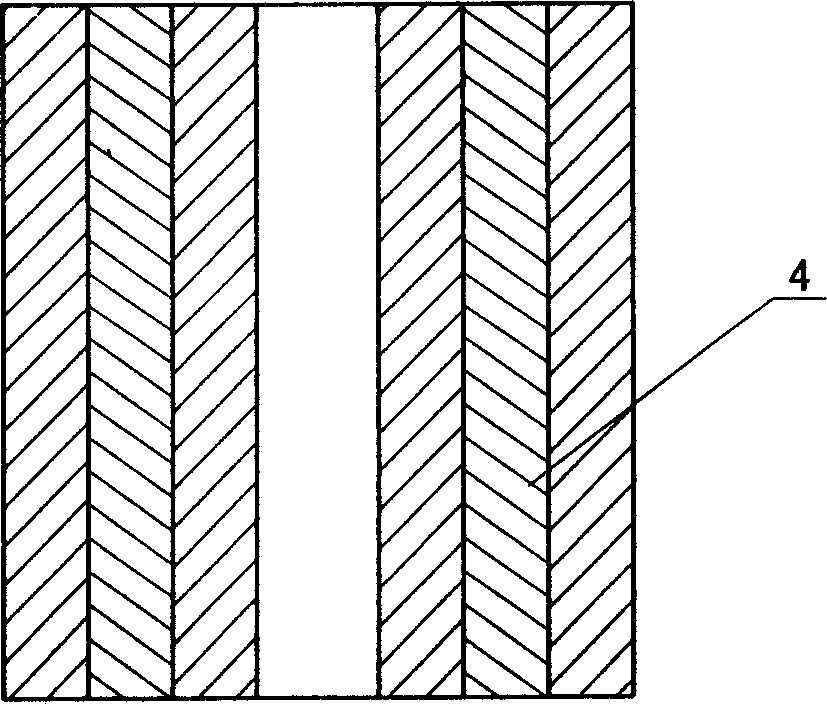

[0054] ③Molding process: evenly vibrate the billet and put it into the mold, then take off the abrasive layer, and perform isostatic pressing. Dry at 60-100°C for 3-6 hours.

[0055] ④Sintering process: the dried body is fired at 1300°C for 1-2 hours to obtain the alumina porous ceramic or ceramic filter element of the present invention.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com