Composite housing type lightning arrester

A composite jacket and lightning arrester technology, which is applied in the field of lightning arresters, can solve the problems of thick valve plates, many processing steps, and difficulties in tooling realization, and achieve the effect of high toughness and few manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

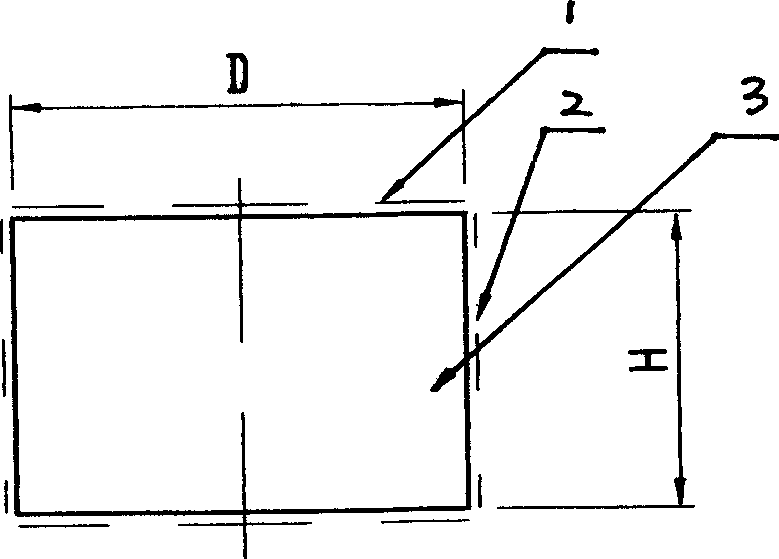

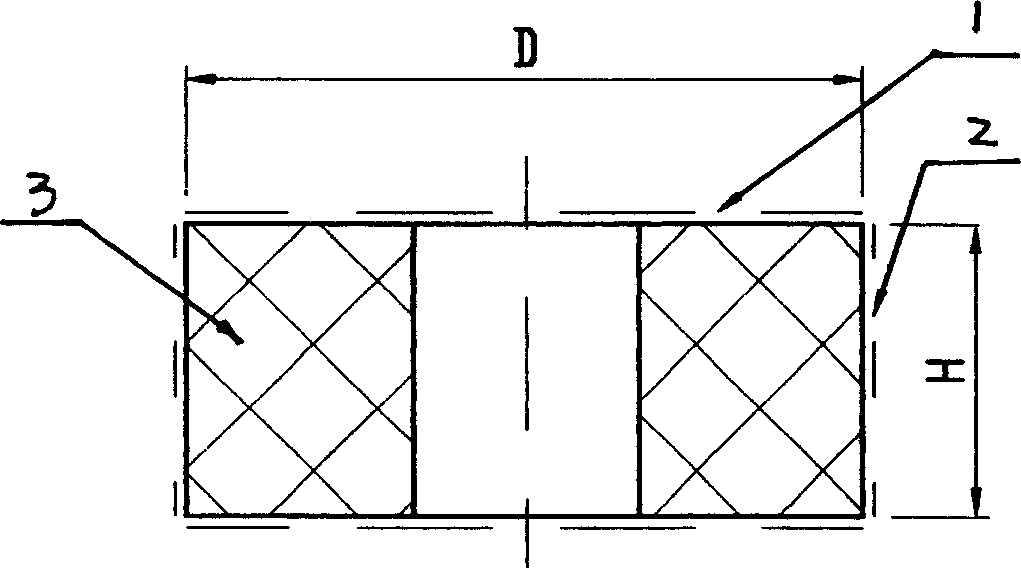

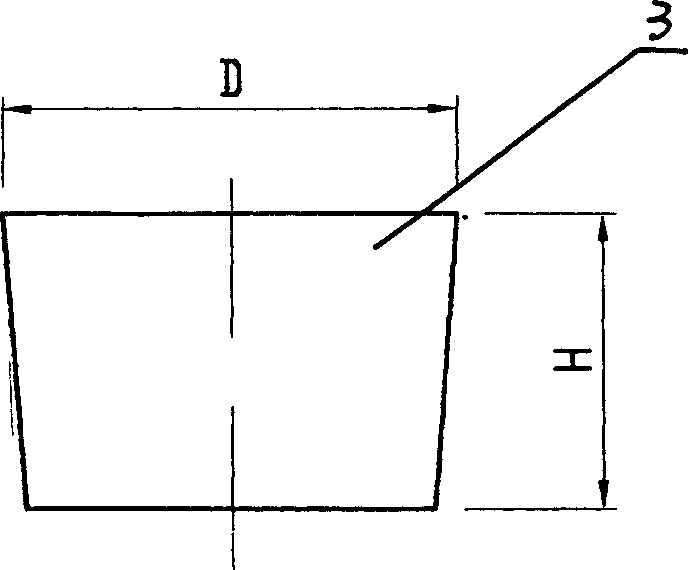

Image

Examples

Embodiment approach 1

[0047] See attached Picture 10 After the long rod-shaped valve body 14 is fired, both ends are coated with silver during heat treatment to form electrodes. The electrical test is qualified, and two metal flanges (that is, the upper metal sleeve 15 and the lower metal sleeve 18) are glued on both ends of the long rod-shaped valve body 14 with conductive adhesive. Coupling the coupling agent on the long rod valve body 14 and the metal flange, and then vulcanizing the weather-resistant composite jacket 5, thereby forming a gapless composite jacket lightning arrester. The long rod valve body 14 bears various natural forces that the arrester should bear through the metal flange. This feature makes it can be used as a lightning arrester and meet the requirements of post insulators, which can be made into insulator arresters or post arresters (see Picture 10 ).

[0048] See attached Picture 12 After the long rod valve body 14 is fired, both ends are coated with silver to form electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com