Dental article and process for surface modification of dental article

A surface modification and product technology, applied in dental preparations, dentistry, dental prostheses, etc., can solve the problems of low resin strength and deformation, and achieve the effect of enhancing bonding performance, beautiful appearance and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

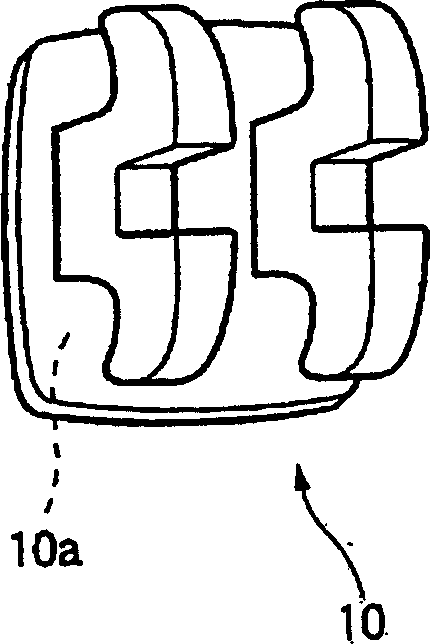

[0095] (Preparation of brackets)

[0096] A polycycloolefin (trade name: Zeonor 1020R; glass transition temperature: 105°C; produced by ZEON Corporation) was subjected to ordinary injection molding to prepare Figure 1A The bracket 10 shown in. The total weight of the ten brackets 10 thus produced was 0.265 g.

[0097] (Surface Modification of Brackets)

[0098] The brackets thus prepared were washed with ethanol at room temperature for 30 minutes, and then dried at 50° C. for 30 minutes.

[0099] Subsequently, an acetone solution containing 3% by weight of polyvinyl acetate as a hydrophilic polymer and 2% by weight of benzophenone as a graft polymerization initiator was coated on the bonding surface of the bracket, and then Dry at 50°C for 30 minutes. Thereafter, 100 ml of an aqueous solution containing 5% by weight of acrylic acid as a reactive monomer was charged into a reaction container made of quartz glass. The bracket was then also placed in the reaction vessel. Th...

Embodiment 2

[0103] The procedure of Example 1 was repeated, except that the polycycloolefin was replaced by a copolymer of cycloolefin and ethylene (Topas6013; heat distortion temperature: 130° C.; manufactured by Mitsui Chemicals Co., Ltd.). The bonding surface of the thus-produced bracket was then subjected to surface modification in the same manner as in Example 1, whereby "bracket B" was obtained.

Embodiment 3

[0105] Brackets were prepared in the same manner as in Example 1. The bonding surface of the bracket thus obtained was then subjected to surface modification in the same manner as in Example 1. Under the illumination that has been filtered to cut off the components of 600nm and below 600nm, use a Bis-GMA (bisphenol A-glycidyl methacrylate) photopolymerizable adhesive (trade name: Ideal lightcure, available from GAC International, USA) Inc.) on the adhesive surface of the bracket thus prepared. The brackets thus coated were then placed in a closed container protected from light for 7 days, thus obtaining "Brackets C".

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com