Electret polypropylene melt-blown nonwovens and method for preparation

A polypropylene melt-blown, non-woven fabric technology, applied in the field of non-woven fabrics, can solve problems such as inability to use liquid filtration, unsuitable for use, etc., to achieve the effect of ensuring quality, stable quality, and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] (1) Manufacture of tourmaline polypropylene masterbatch

[0058] First, 100 parts by weight of tourmaline particles, 4.5 parts by weight of low molecular weight polyethylene wax and 0.1% of antioxidant 1010 powder are poured into a high-speed mixer, and stirred for 5 minutes at a speed of 2500r / min; then 10 parts by weight of titanic acid The coupling agent diluted in petroleum ether with twice the volume of titanate was added to the high-speed mixer three times, stirring for 10 minutes between each time; it was taken out and vacuum-dried at about 100°C for 2 hours.

[0059] Next, pour the modified tourmaline particles and 400 parts by weight of polypropylene slices into a high-speed mixer and mix again for 10 minutes. Finally, put the mixed raw materials into a twin-screw compounding extruder and melt them at a temperature of about 150°C. Extruded, cooled in a water bath, cut into tourmaline polypropylene masterbatch.

[0060] (2) Manufacture of electret polypropylene...

Embodiment 2~9

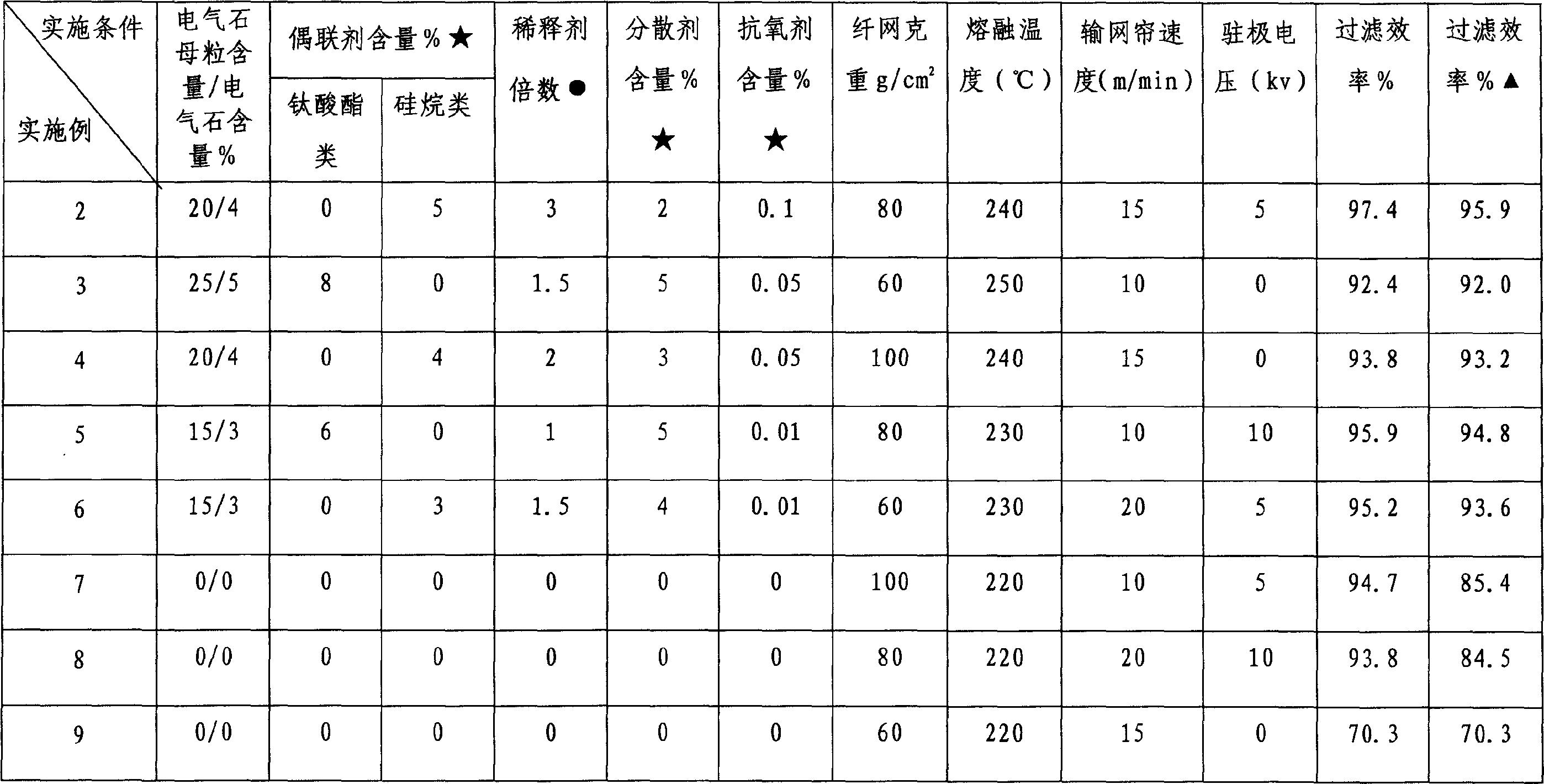

[0065] In Examples 2 to 9, Examples 3 and 4 are examples of electret polypropylene melt-blown nonwovens of the present invention, which are designed for filtering liquids; Describe the embodiment of composite electret polypropylene melt blown nonwoven fabric; And embodiment 7,8,9 then is the general polypropylene melt blown that compares with the electret polypropylene melt blown nonwoven fabric of the present invention Examples of nonwoven fabrics, but the process of Examples 2 to 9 is basically the same as that of Example 1, except that the processing conditions or parameters are different. For clarity, the specific process conditions or parameters of Examples 2-9 are listed in Table 1 uniformly.

[0066] The specific process data sheet of table 1 embodiment 2-9

[0067]

[0068] ★Percentage of tourmaline weight ●Multiple of volume of coupling agent ▲Refers to filtration efficiency after heat treatment, heat treatment temperature 80℃, relative humidity 80%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com