Computerized controller for industrial sewing machine

An industrial sewing machine and controller technology, applied in sewing equipment, program-controlled sewing machines, textiles and papermaking, etc., can solve the problems of low parking accuracy, cumbersome operation, bulky volume, etc., and reduce peripheral circuit devices and signal interference. , the effect of reducing the size of the circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

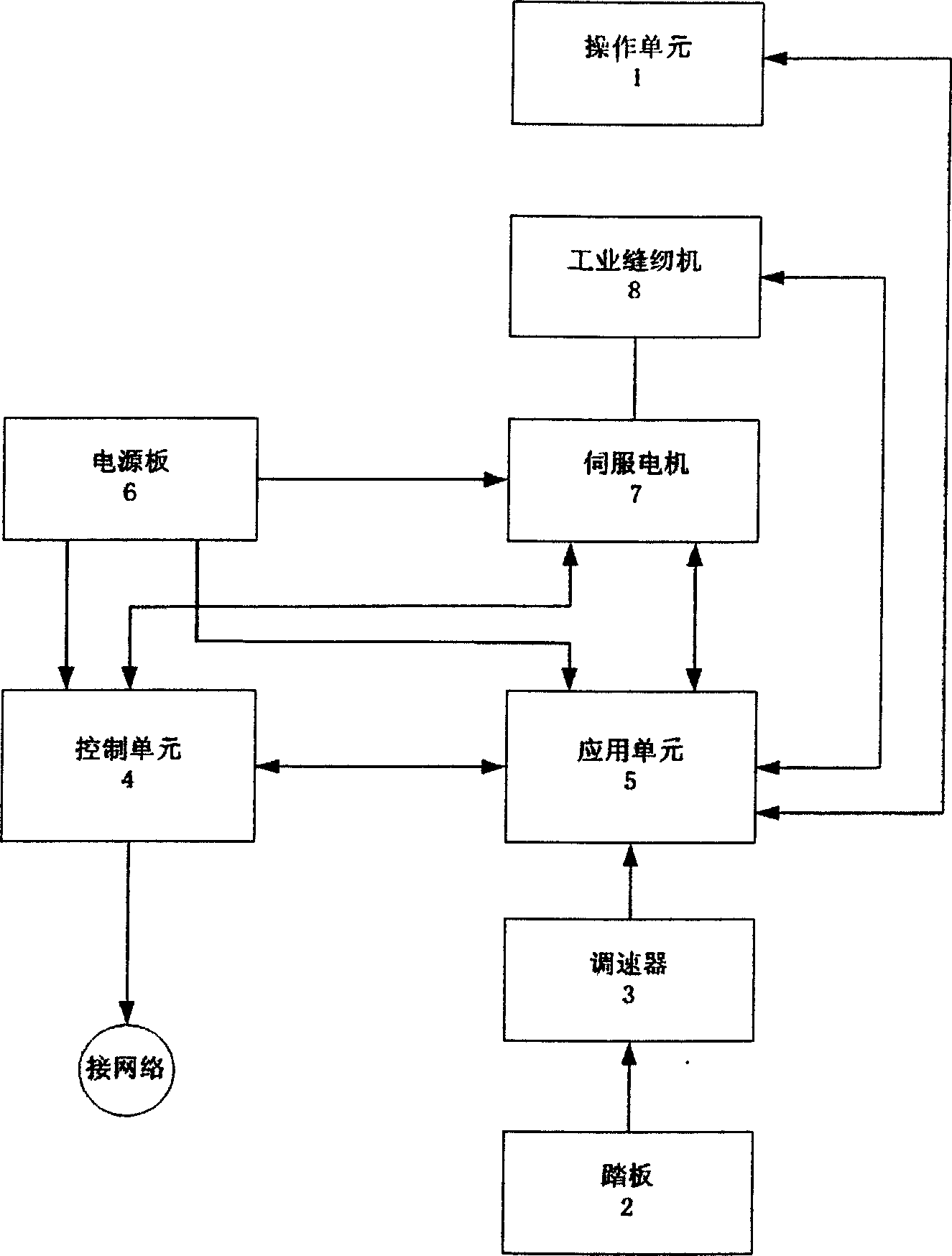

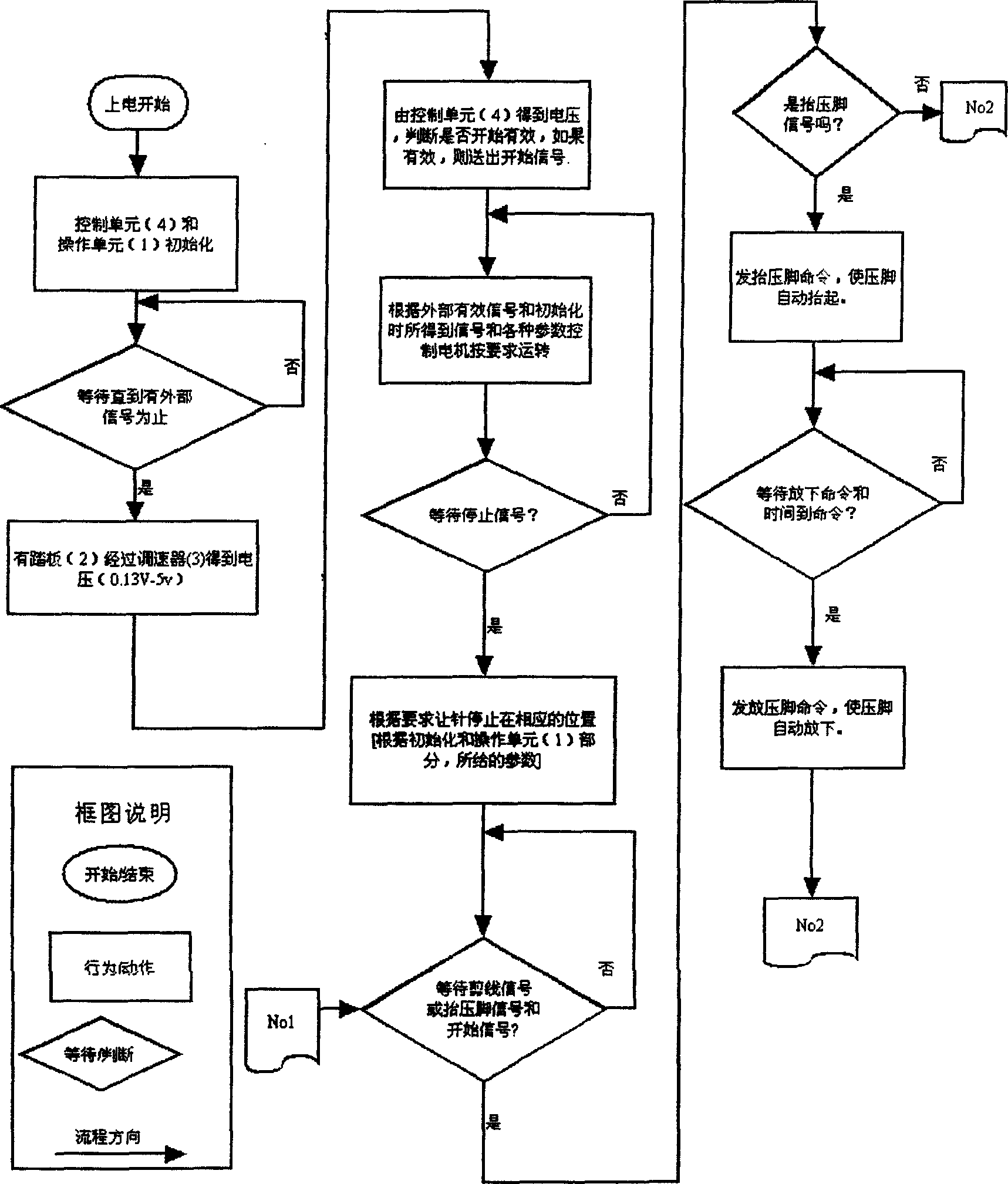

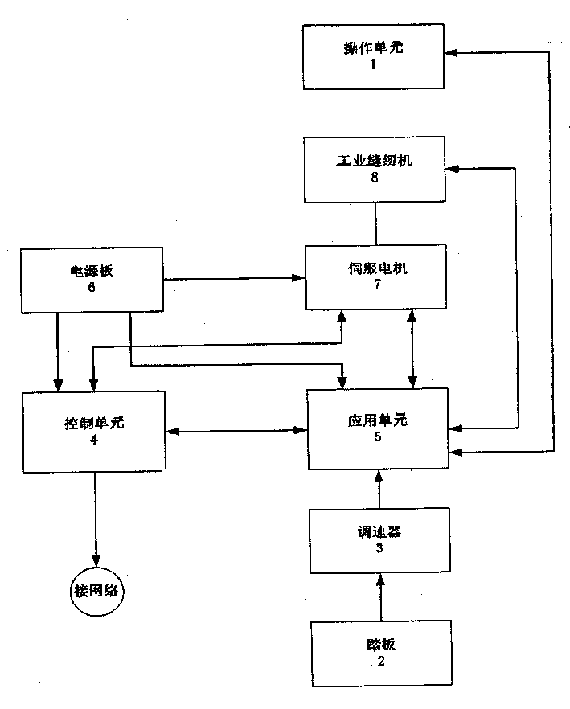

[0010] Embodiment: the system composition of the present invention is as figure 1 shown. The control unit (4) includes a DSP board and a power control board. The DSP board mainly adopts a DSP chip and peripheral components. The DSP chip adopts the TMS320F240 series of Texas Instruments. The DSP chip is responsible for all motor interfaces and the photoelectric encoder control of the sewing machine. The power control board contains a three-phase pulse width modulation (PWM) converter, which is responsible for PWM power amplification and motor electronic dynamic brake control; the application unit board (5) contains an 89C51 single-chip microcomputer, which is mainly responsible for various applications of industrial sewing machines, such as Pattern storage, sewing program, stitch compensation and other application control; the power board (6) provides the power required by each component; the servo motor (7) adopts a 550W, 3000RPM brushless DC motor, including a three-phase Hal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com