Metal mask plate

A metal mask, metal mask technology, applied in optics, instruments, opto-mechanical equipment, etc., can solve the problems of troublesome and complicated production, high cost, expensive investment, etc., so as to reduce the cost of lithography equipment and reduce the difficulty of production technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

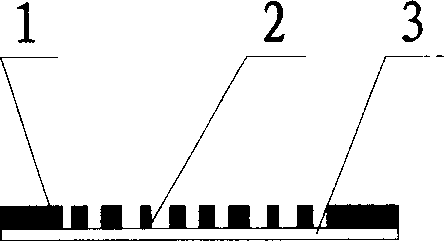

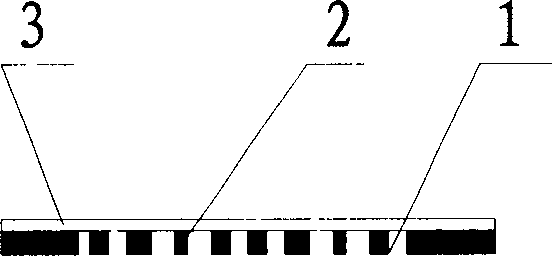

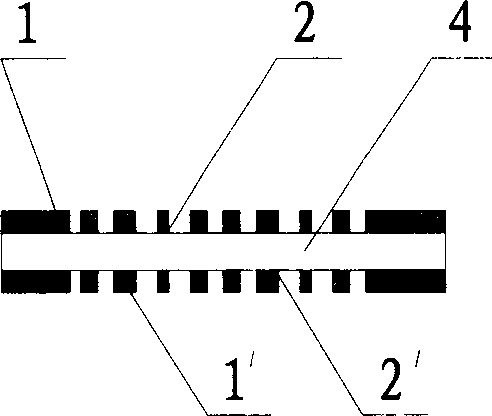

[0018] Such as figure 1 As shown, embodiment 1 of the present invention is made up of chromium mask pattern thin layer 2, the sio2 film or substrate 3 positioned below and the metal mask pattern book layer 1 with the same pattern as the chromium mask pattern layer 2 above, wherein The thickness of the sio2 thin film or substrate 3 is at least 1 μm, the thickness of the chromium mask pattern thin layer 2 is 5-150 nm, and the metal material of the metal mask pattern book layer 1 is gold, silver or copper or aluminum, and its thickness is 5 nm. -150nm. The general wavelength or long wavelength laser can pass through the nanometer metal mask whose pattern size is much smaller than the wavelength, because the metal mask with ultrafine pattern produces a surface with a very short wavelength under the irradiation of general wavelength or long wavelength laser. Plasma wave, the plasma wave can pass through the holes and slots of the thin layer 2 pattern of the nano-chromium mask patt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com