Method for preparing octyl group micro column liquid phase chromatograph integrate column

A technology of liquid chromatography and monolithic column, which is applied in the field of preparation of micro-column liquid chromatography monolithic column, which can solve the problem of low chromatographic capacity and achieve the effects of simple preparation, strong stability and high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

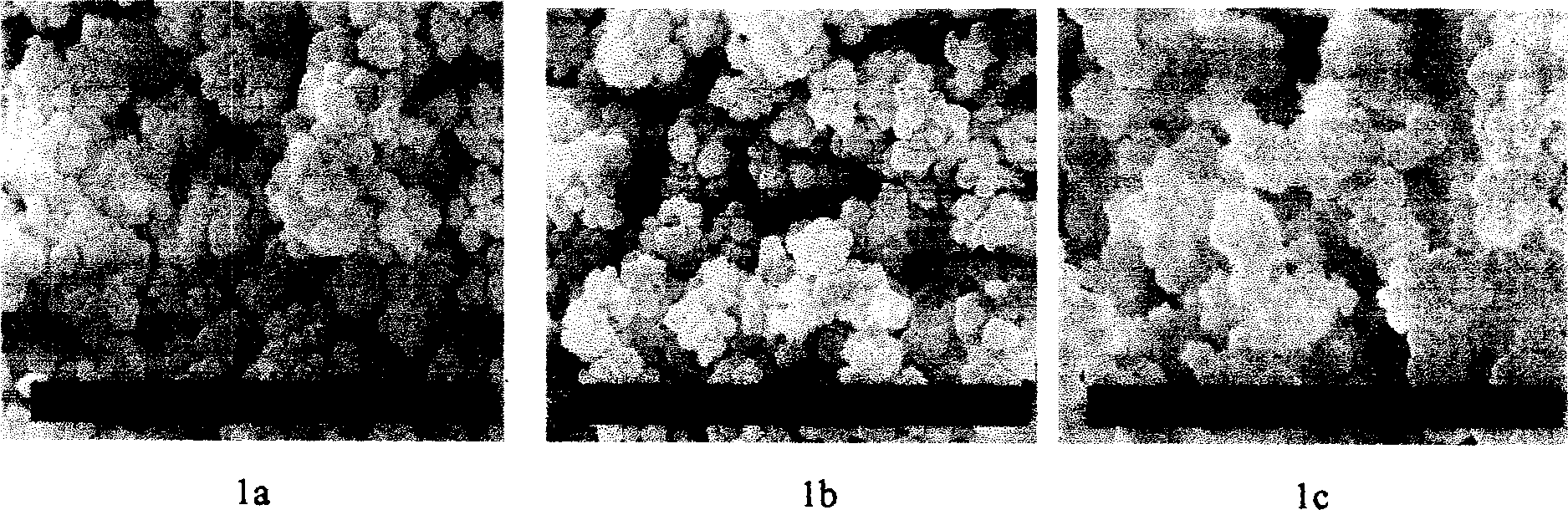

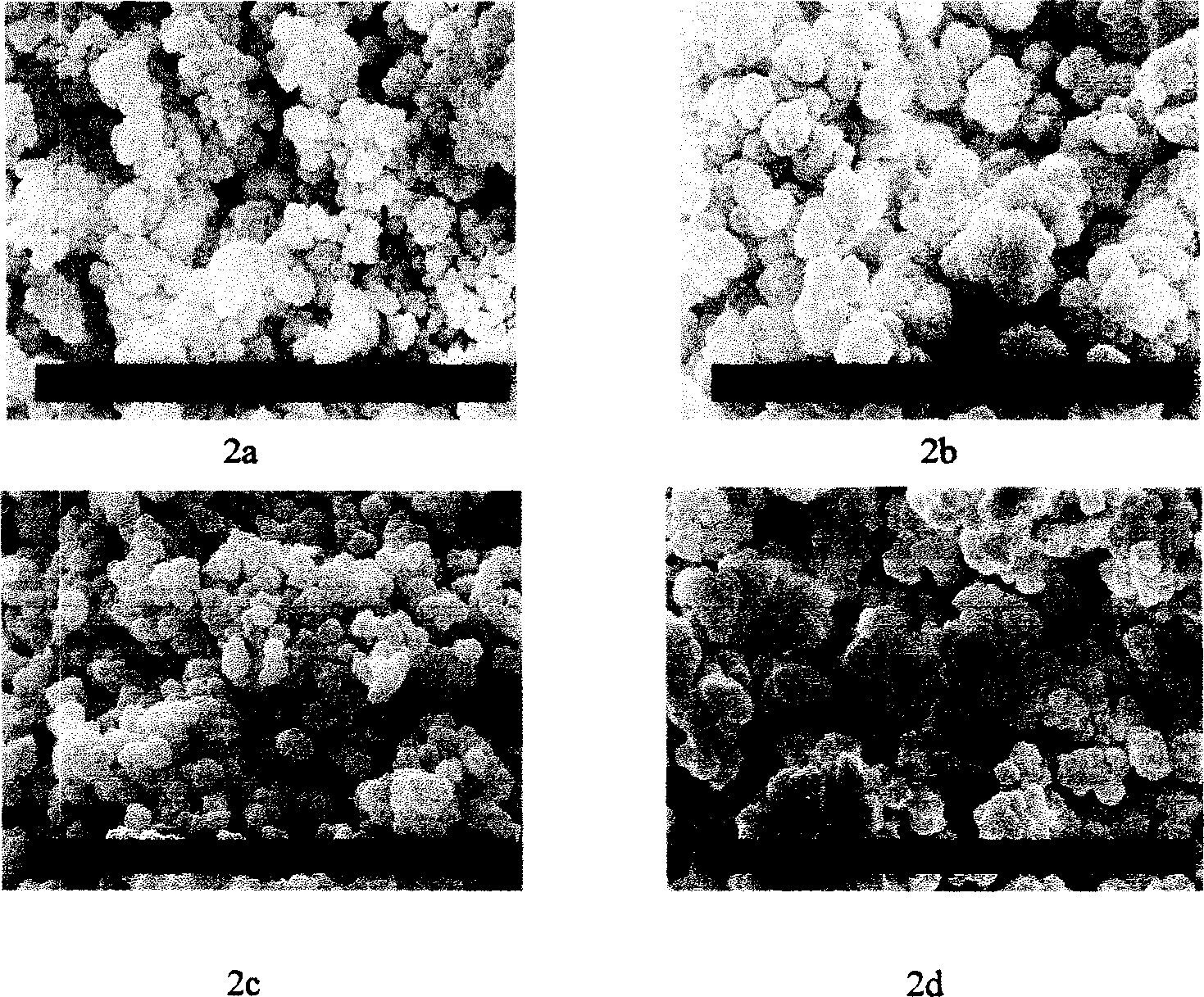

Image

Examples

Embodiment 1

[0023] 1) Cleaning treatment of the inner wall of the capillary: take a quartz glass capillary with an inner diameter of 530 μm and a length of 5 m, wash it with 0.1 mol / L HCl solution at a flow rate of 1.0 mL / min for 0.5 h, and then use deionized water at a flow rate of 1.0 mL / min. Rinse at a flow rate until the washing solution is neutral, then rinse with 0.1moL / L NaOH solution at a flow rate of 1.0mL / min for 2.0h, rinse with deionized water at a flow rate of 1.0ml / min until the washing solution is neutral, and finally use methanol to After flushing at a flow rate of 1.0mL / min for 15min, purging with nitrogen for 2h.

[0024] 2) Pre-bonding of the inner wall of the capillary: Prepare 3.0 mL of a mixed solution of γ-methacrylateoxypropyltrimethoxysilane (γ-MAPS) and methanol (γ-MAPS:MeOH=1:0.5), and then add 3 μL of dry Pyridine, ultrasonically degassed for 10 minutes, injected into the pretreated capillary with a syringe, sealed with rubber stoppers at both ends of the capil...

Embodiment 2

[0027] The cleaning treatment of the inner wall of the capillary is the same as in Example 1. In the pre-bonding of the inner wall of the capillary, 3.0 mL of a mixed solution of γ-methacryloxypropyltrimethoxysilane (γ-MAPS) and methanol (γ-MAPS: MeOH=1 : 1), then add 6 μL of pyridine, inject it into the pretreated capillary, seal both ends of the capillary, place it at 45° C. for 12 h, purging with nitrogen for 2 h, and seal both ends for later use. Configure the reaction monomer mixture, wherein MAOE: EDMA: AIBN=59.5%: 39.5%: 1%; the ratio between the porogen mixture is: propanol 60%, 1,4-butanediol 30%, water 10% ; The ratio between the reaction monomer mixture and the porogen mixture is 35%: 65%; Use a syringe to draw the reaction solution into a pre-bonded empty capillary tube with a length of 23 cm and an inner diameter of 250 μm, seal both ends with rubber plugs, and react at 60 ° C for 12 hours. After the reaction, connect it to the liquid chromatography pump and use ...

Embodiment 3

[0029] Take a capillary with an inner diameter of 50 μm, and the cleaning treatment of the inner wall is the same as in Example 1. In the pre-bonding of the inner wall of the capillary, 3.0 mL of a mixed solution of γ-methacryloxypropyltrimethoxysilane (γ-MAPS) and methanol (γ-MAPS) was prepared. MAPS:MeOH=1:1.5), then add 9 μL of triethylamine, inject it into the pretreated capillary, seal both ends of the capillary, place it at 50°C for 24 hours, purging with nitrogen for 4 hours, and seal both ends for later use . Configure the reaction monomer mixture, wherein MAOE: EDMA: AIBN is 59.5%: 39.5%: 0.5%; the ratio between the porogen mixture is: propanol 70%, 1,4-butanediol 20%, water 10% ; The ratio between the reaction monomer mixture and the porogen mixture is 40%: 60%, and the mixture is injected into an empty capillary tube with an inner diameter of 50 μm and a length of 23 cm. Finally, connect to the liquid chromatography pump and rinse with methanol for 6 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com