Improved compositions, methods and devices for high temperature lead-free solder

A composition, solder technology, applied in welding/cutting medium/material, welding equipment, welding medium, etc., can solve problems such as poor mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

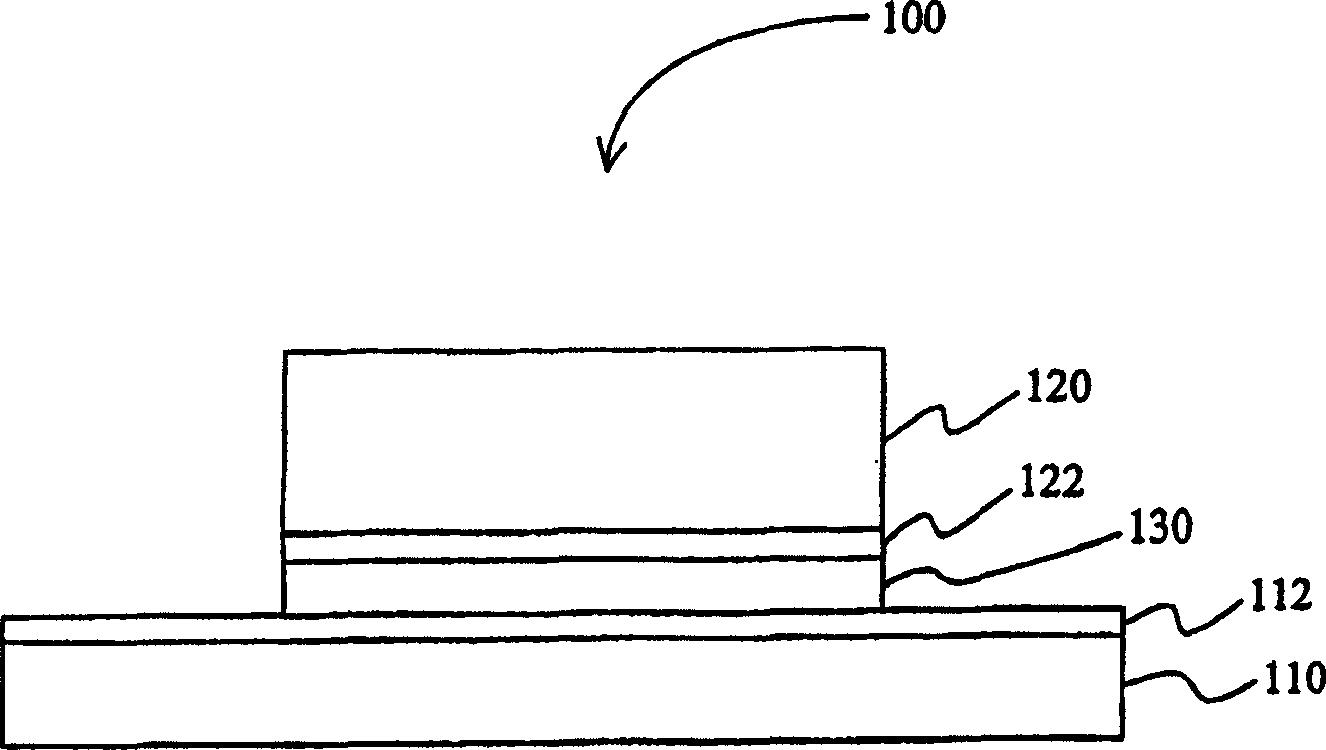

[0047] Solder joints are often subjected to shear loads due to differences in the coefficients of thermal expansion of different materials. Therefore, alloys joining these materials are particularly desirable to have a lower shear modulus and thus better thermomechanical fatigue resistance. For example, in die attach applications, especially when relatively large dies are attached to a carrier, the low shear modulus and better thermomechanical fatigue resistance help prevent die cracking.

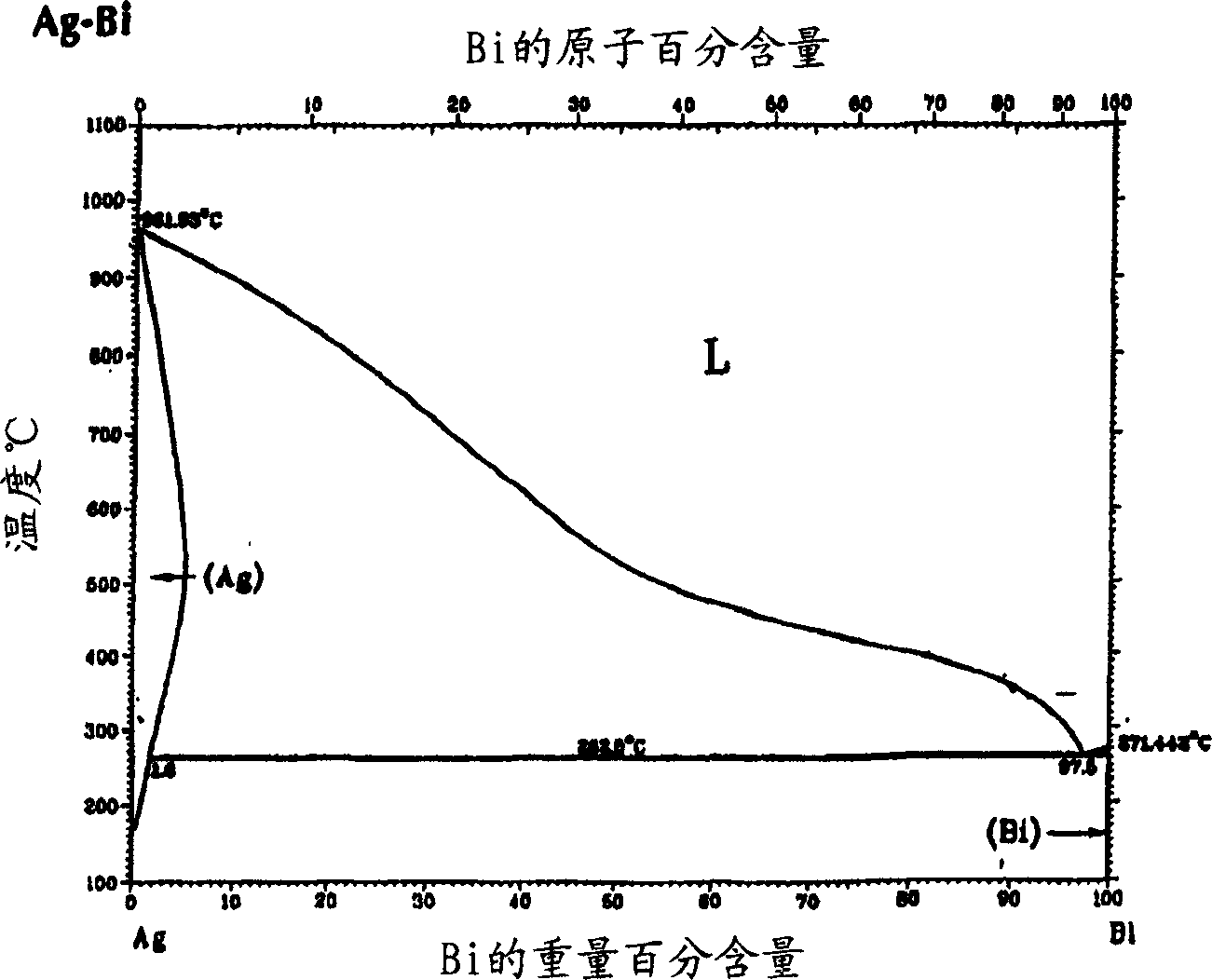

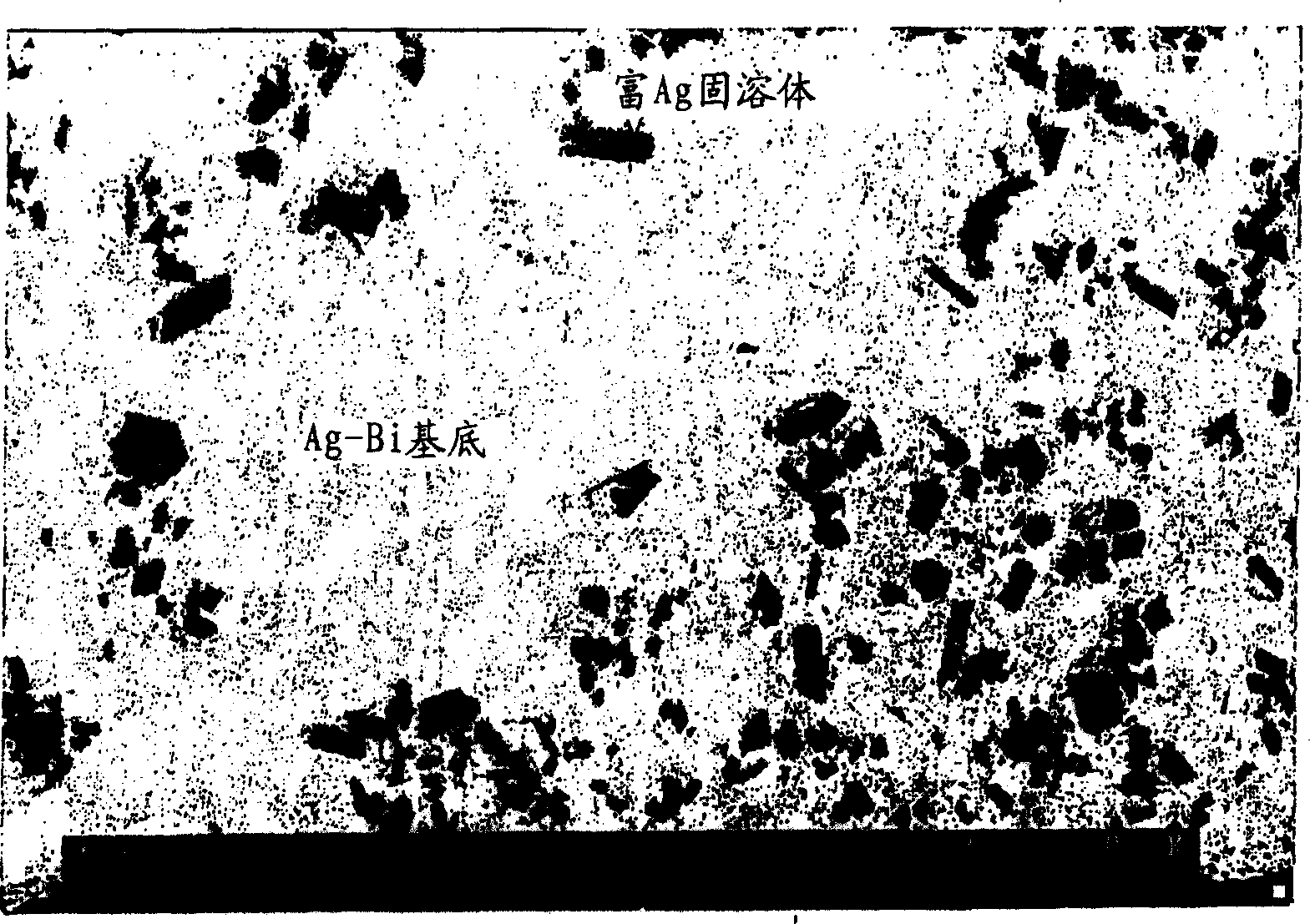

[0048] Based on the known elastic moduli of pure metals, the fact that Ag and Bi show partial solid mutual solubility, and the fact that the Ag-Bi system contains no intermetallic or intermediate phases, the expected room temperature shear for Ag-Bi alloys has been calculated The shear modulus is in the range of about 13-16 GPa (assuming room temperature shear moduli are additive, ie subject to the law of mixtures). Compared to 25GPa for Au-25%Sb and Au-20%Sn alloys (calculated using the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com