Process of preparing magnesium boron oxygen nano thread

A nanowire and boron-oxygen technology, which is applied in the field of preparation of magnesium boron-oxygen nanowires, can solve the problems of many impurities, difficult to remove, complex equipment, etc., and achieve the effect of simple process, improved mechanical properties and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Magnesium nitrate (Mg(NO 3 ) 2 Analytical purity 99%), boric acid (H 3 BO 3 Analytical purity 99%) and citric acid (C 6 h 8 o 7 ·H 2 (analytical purity 99%)) by molar ratio of magnesium nitrate: boric acid: citric acid = 1: 2: 5 solution, dried at 150 ° C to make a gel, then roasted at 750 ° C for 4 hours to generate white powder The white powder obtained above was dissolved in water, and the soluble B was removed by centrifugation. 2 o 3 Impurities, to get MgB 4 o 7 nanowires.

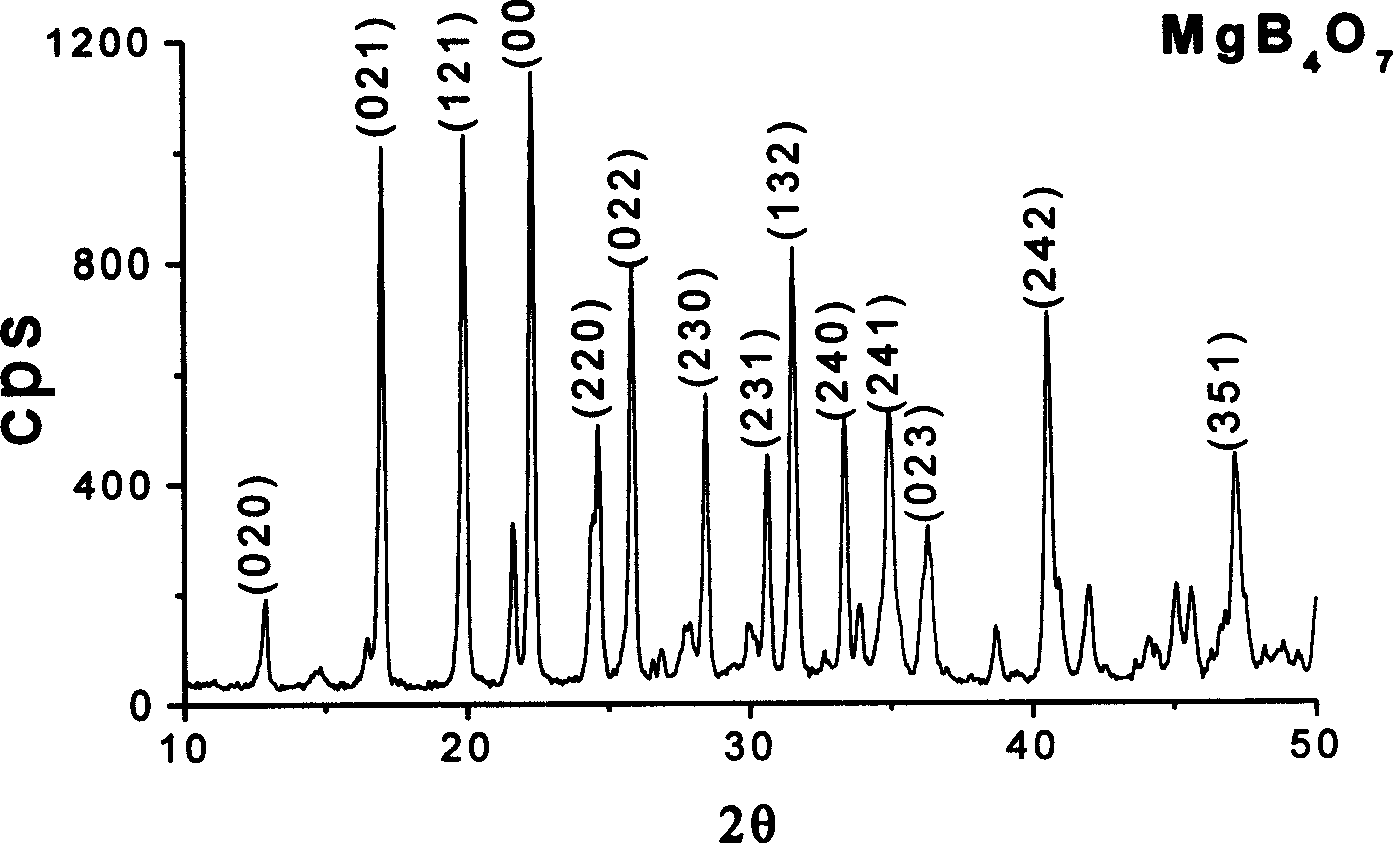

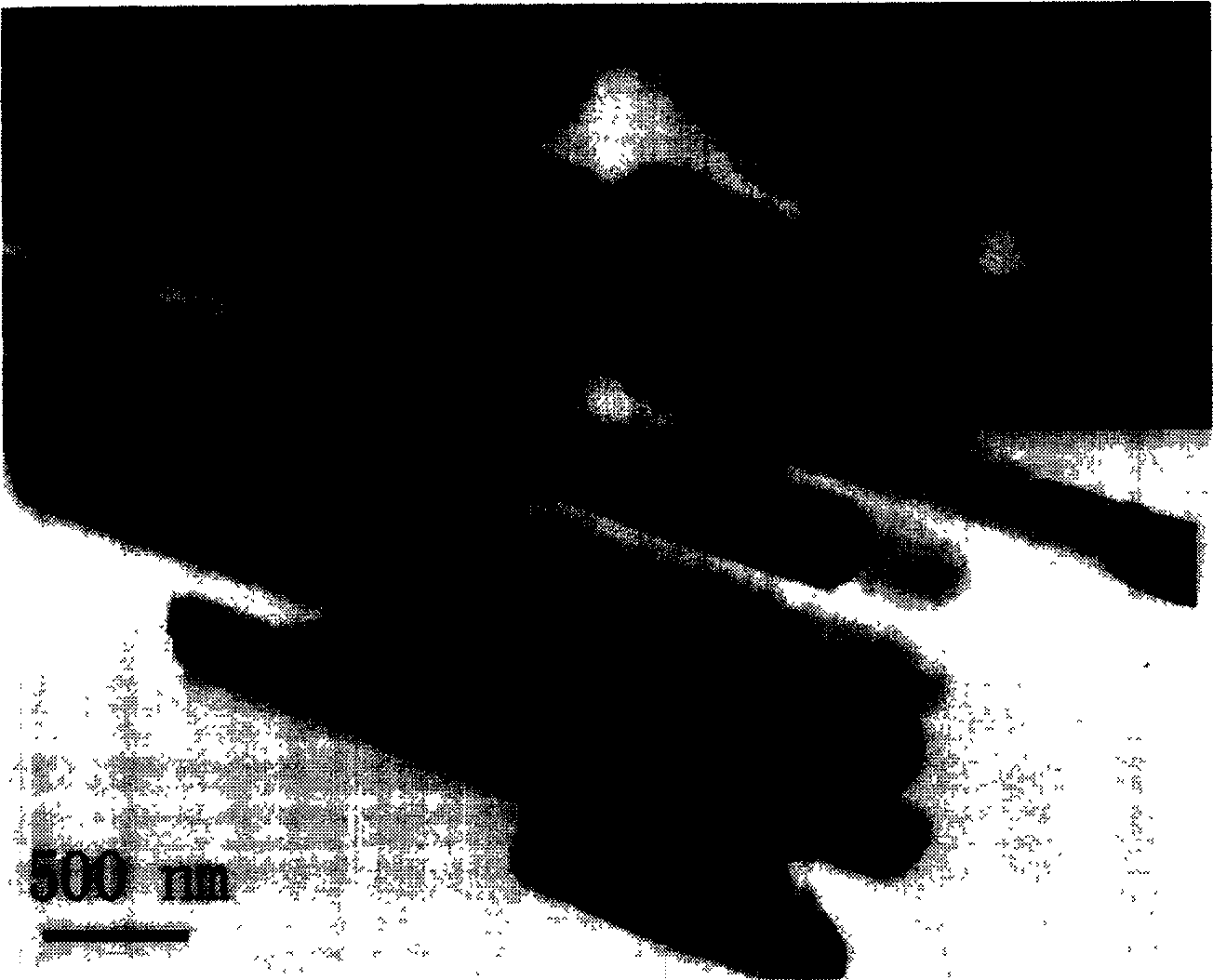

[0016] will dissolve B 2 o 3 MgB 4 o 7 Nanofilaments were detected by XRD (see figure 1 ), the experiments showed that the crystallization of nanowires will be better with the prolongation of calcination time. Using a scanning electron microscope (see figure 2 ) and transmission electron microscopy (see image 3 ). The results show that the magnesium boron oxygen nanowires produced by the sol-gel method are relatively uniform in diameter, about 500nm, and the length is in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com