Method for synthesizing Yiyuyin through catalysis of acetaldehyde

A technology of acetaldehyde catalysis and acetoin, which is applied in chemical instruments and methods, preparation of carbon-based compounds, preparation of organic compounds, etc., can solve the problems of difficult purification of products, high cost, increased production cost, etc., and achieves less by-products. , the effect of high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

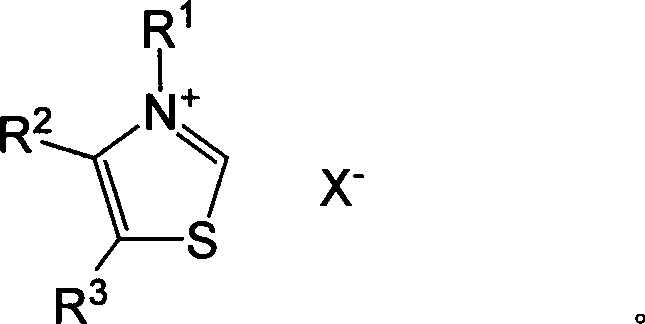

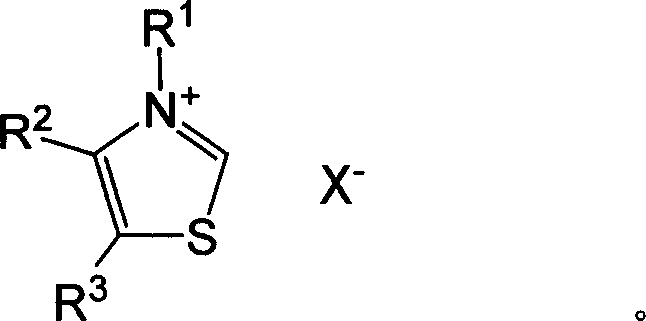

Method used

Image

Examples

Embodiment 1

[0014] 700 grams of acetaldehyde and 7 grams of ((1wt%) 5-benzyl-4-(N-methyl-N-anilino)-3-octyl-1,3-thiazole chloride salt were added to the two-liter autoclave , start stirring and heat up, control the reaction temperature at 100° C., and the reaction time is 5 hours. Gas chromatography analysis after the reaction shows that the conversion rate of acetaldehyde is 85%, and the product selectivity is 94%.

Embodiment 2

[0016] 700 grams of acetaldehyde and 7 grams of ((1wt%) 5-benzyl-4-(N-methyl-N-anilino)-3-octyl-1,3-thiazole chloride salt were added to the two-liter autoclave , start stirring and heat up, control the reaction temperature at 120° C., and the reaction time is 3 hours. Gas chromatography analysis after the reaction shows that the conversion rate of acetaldehyde is 93%, and the product selectivity is 97%.

Embodiment 3

[0018] 700 grams of acetaldehyde and 7 grams of ((1wt%) 5-benzyl-4-(N-methyl-N-anilino)-3-octyl-1,3-thiazole chloride salt were added to the two-liter autoclave , start stirring and heat up, control the reaction temperature at 140° C., and the reaction time is 0.5 hour. Gas chromatography analysis after the reaction shows that the acetaldehyde conversion rate is 98%, and the product selectivity is 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com