ZnO based transparent thin film transistor and its prepn. method

A thin-film transistor and thin-film technology, which is applied in the field of ZnO-based thin-film transistors and their preparation, can solve problems such as restricted fields of work, opacity, etc., and achieve the effects of cost reduction, simple production process, and easy application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

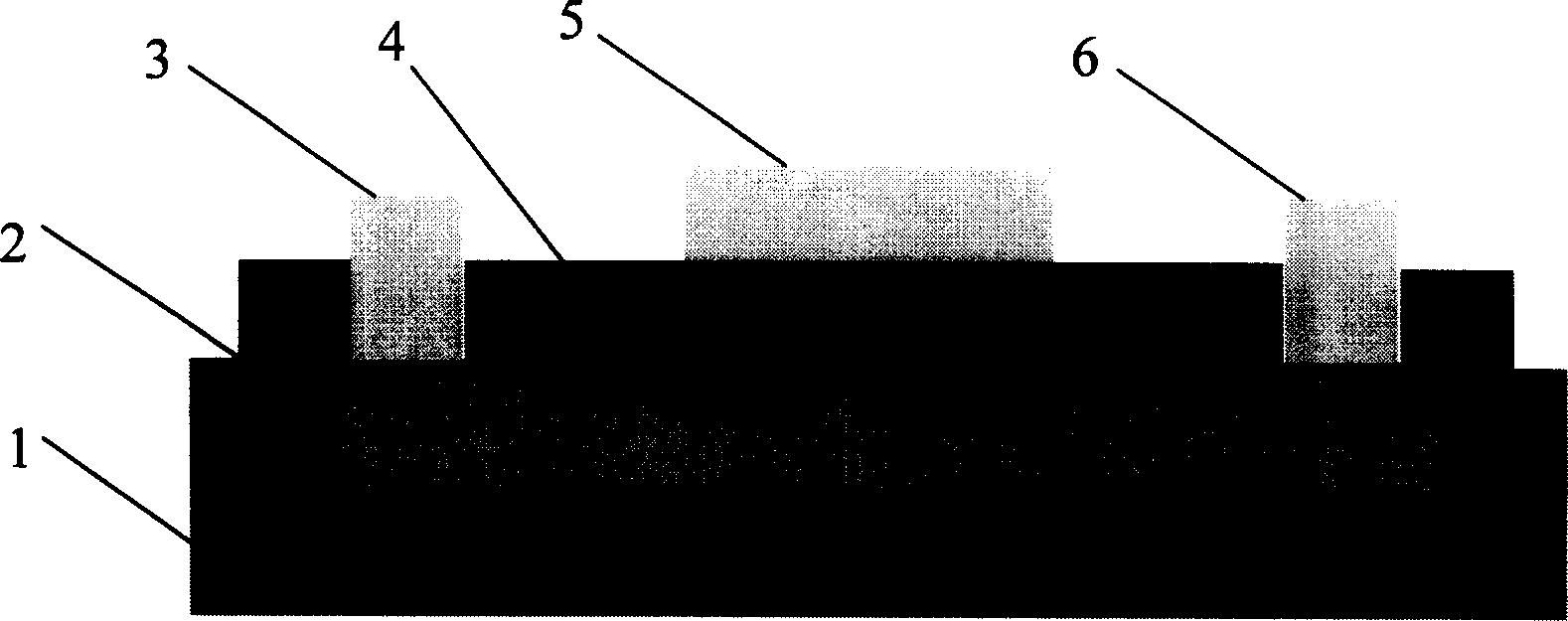

[0016] Refer to attached figure 1 , illustrating the structure and implementation method of the ZnO-based thin film transistor of the present invention: deposit n-ZnO thin film 2 on the substrate 1, and then conduct the first photolithography to separate small transistor units. Then rapid thermal annealing (RTA) (600-800°C O 2 atmosphere) to increase the channel resistance and improve the crystallization properties of ZnO. Then uniformly coat a layer of photoresist on the surface, engrave a pattern with a photolithography layout, and then deposit a layer of ATO film 4 as a gate insulating layer, and engrave an electrode window by a lift-off process. Then rapid thermal annealing (RTA) (600-800°C O 2 atmosphere) to improve the electrical properties of the ATO / ZnO interface. Then deposit the ITO thin film transparent electrode, and use wet photolithography to form the source electrode 3, the gate electrode 5, and the drain electrode 6. Rapid thermal annealing at 300°C is then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com