Rotor permanent magnet conversion governing dynamo and its hub electric wheel

A variable frequency speed regulating motor and rotor technology, which is applied to synchronous motors with static armatures and rotating magnets, electric components, magnetic circuit rotating parts, etc. The low utilization rate affects the efficiency of the whole vehicle and affects the layout of the whole vehicle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

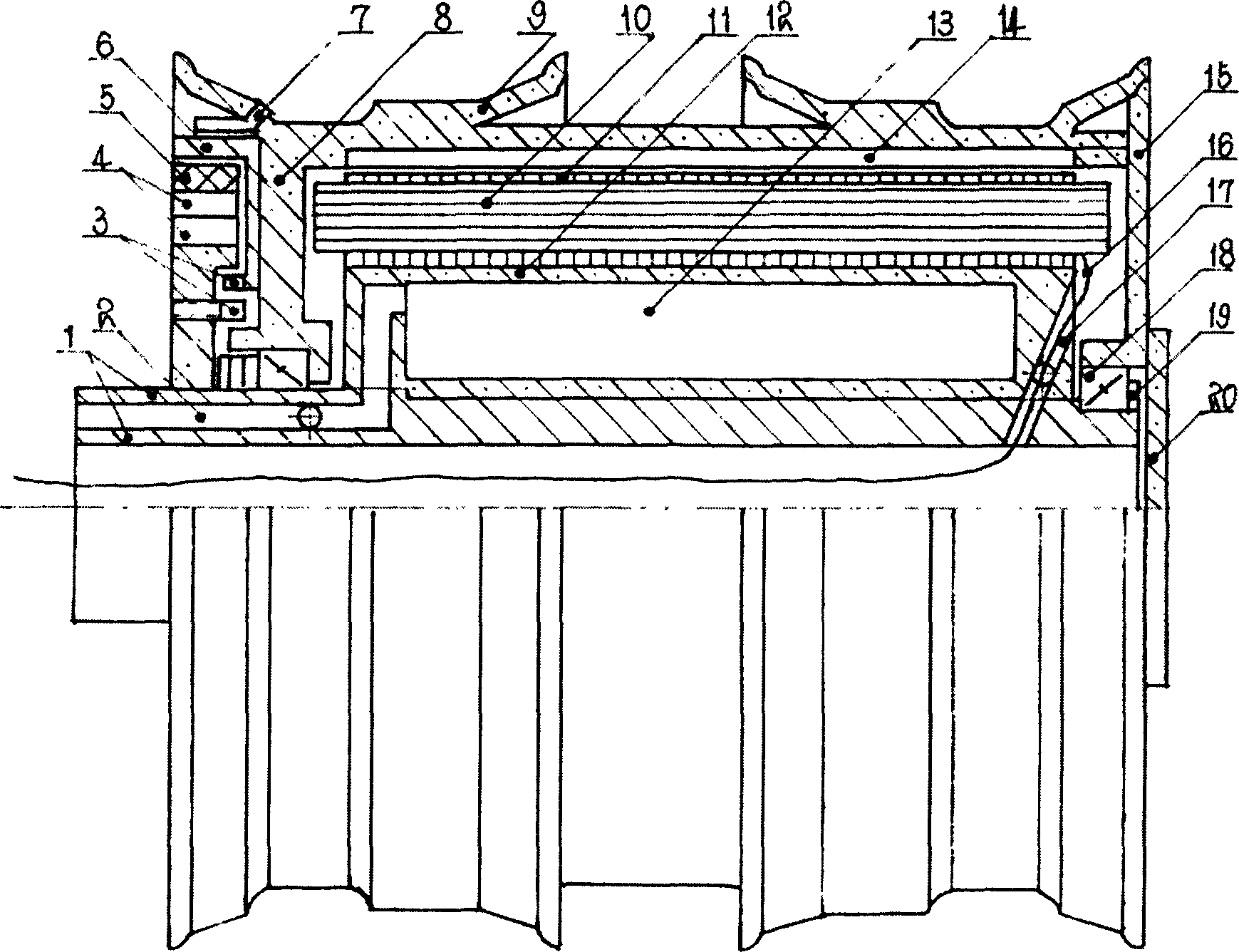

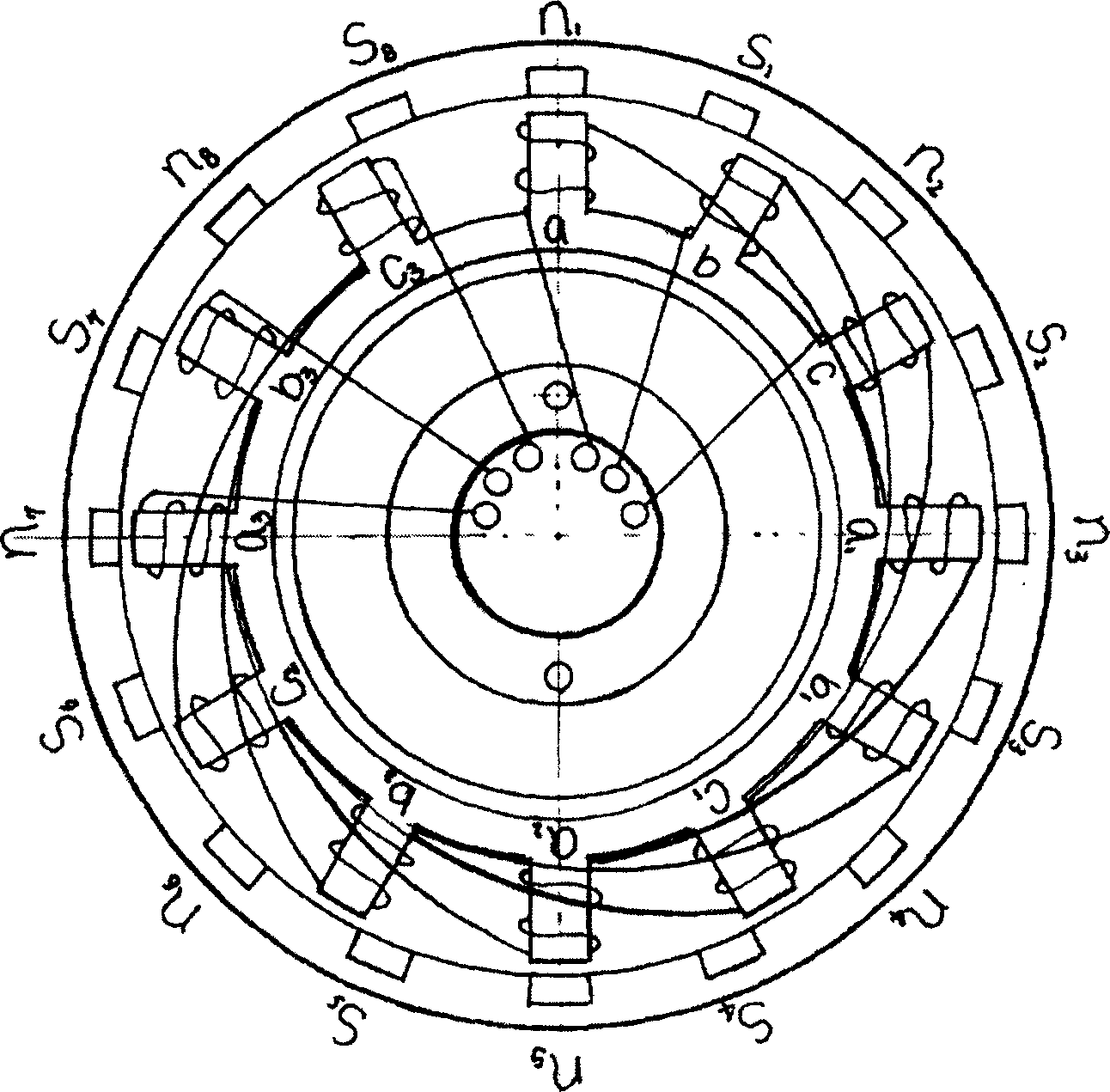

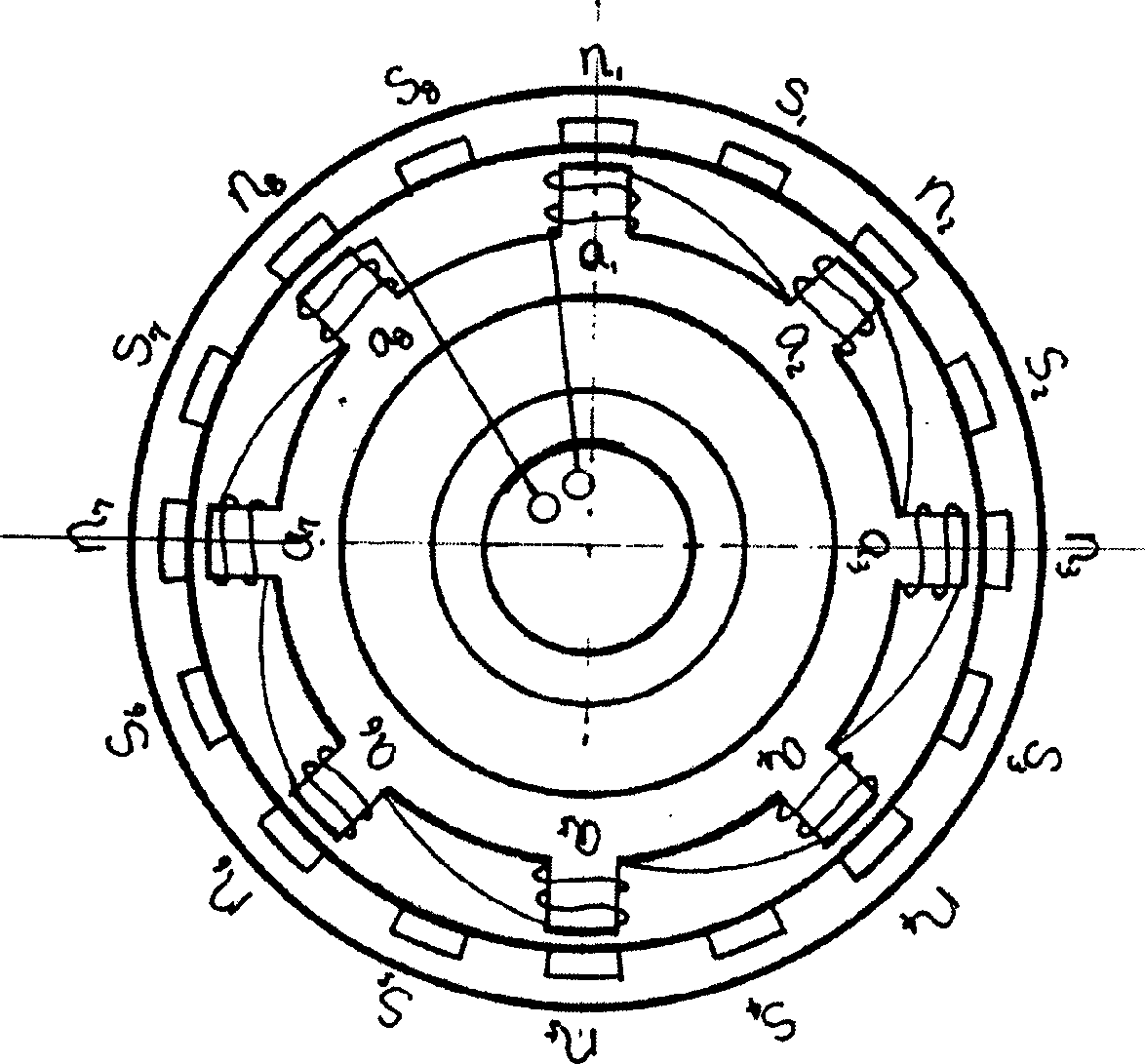

[0012] The three-stroke rotor permanent magnet variable frequency speed regulating motor is a rotor permanent magnet switch frequency conversion speed regulating three-phase motor. The stator and rotor are salient pole structures; the stator is made of silicon steel sheets, and the rotors are staggered in the order of N-S-N- It is inlaid with permanent magnets on the tile surface; the structure of its hub electric wheel is as follows: figure 1 Shown: The motor is an outer rotor type, and the stator winding is integrated with the motor shaft, that is, the wheel shaft. A cooling chamber 13 is provided between the hollow shaft 1 and the iron core 11. It is made of a carrier 12 cast from magnesium-aluminum alloy with good thermal conductivity and high strength. For the passage hole 17 of the wire 16 leading to the stator winding 10 through the wall of the cooling chamber, a simple concentrated excitation winding 10 is provided on the salient pole of the iron core 11, and the windi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com