Method of making liquid crystal display

A technology of liquid crystal display and manufacturing method, which is applied to static indicators, instruments, transistors, etc., can solve the problems of difficulty in controlling the leakage current, complicated manufacturing process, and low image quality, so as to avoid risks and probability, improve Electrical performance, the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

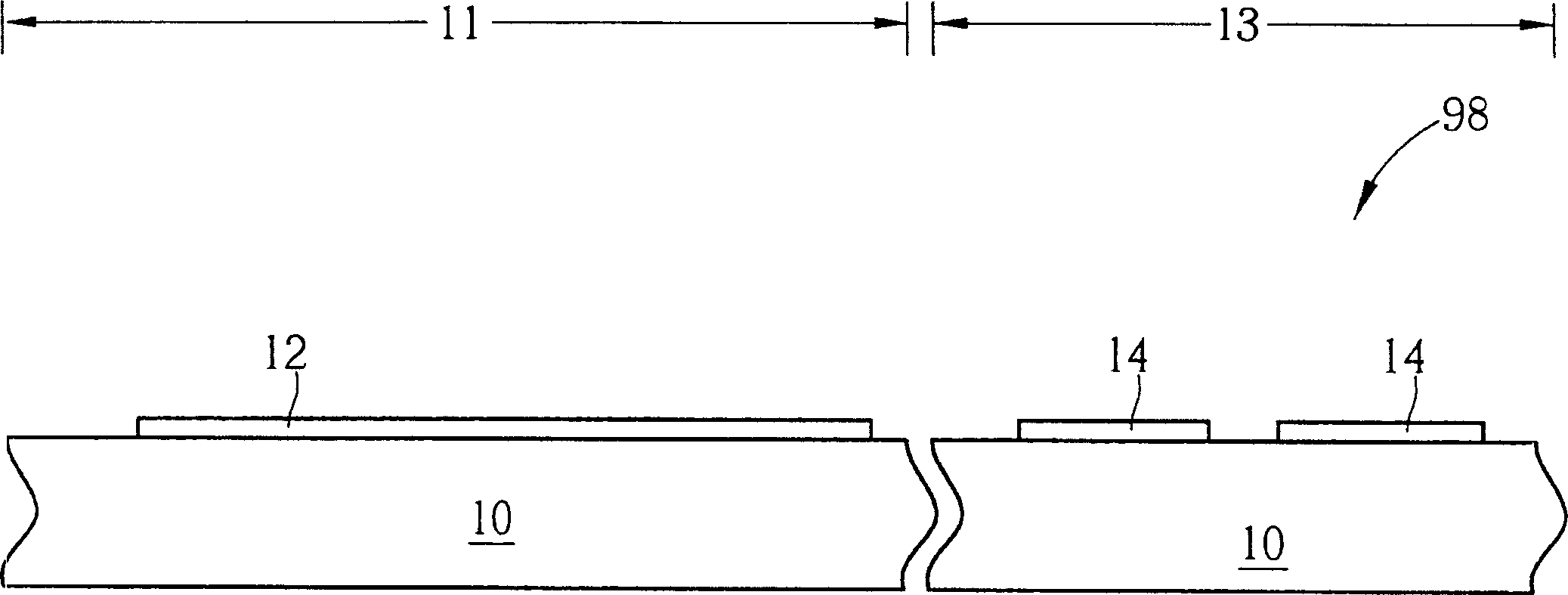

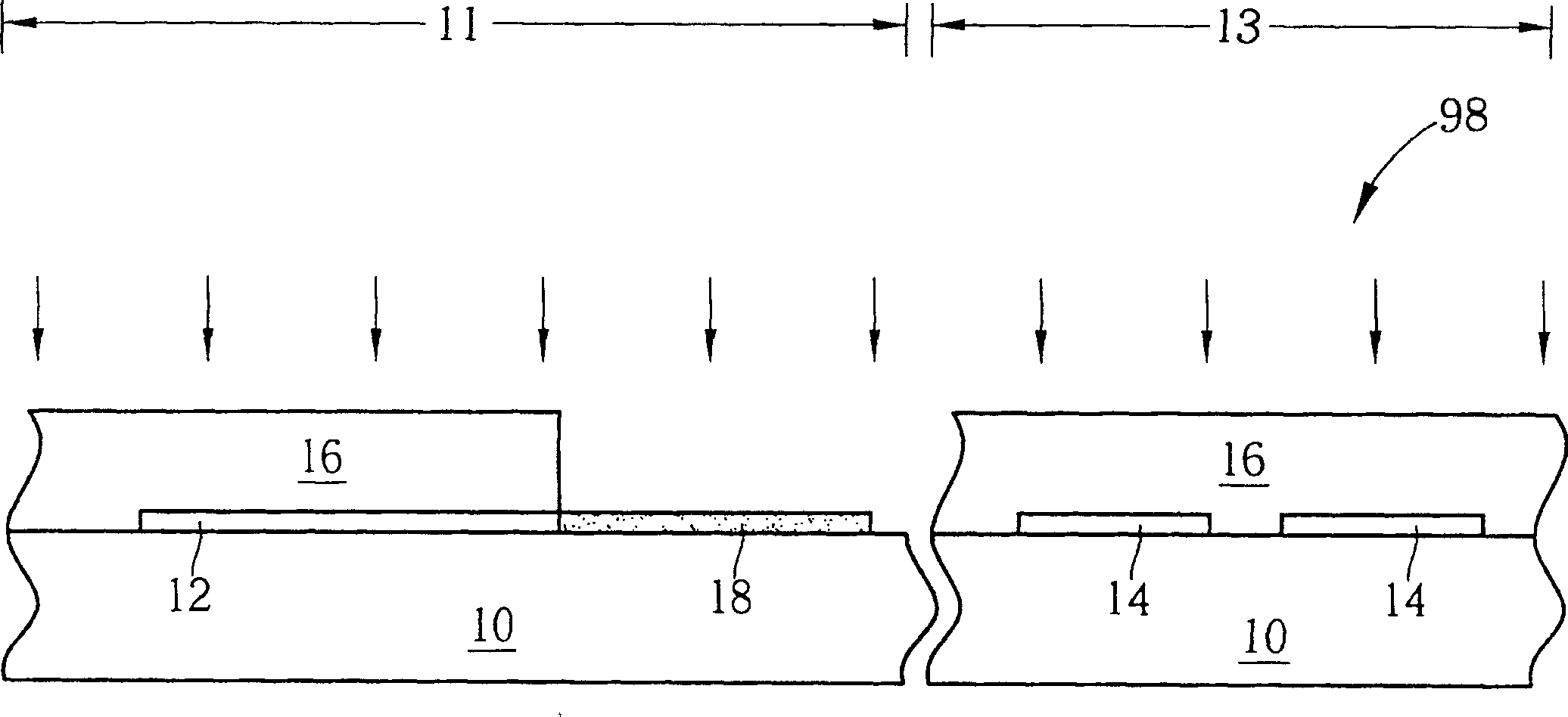

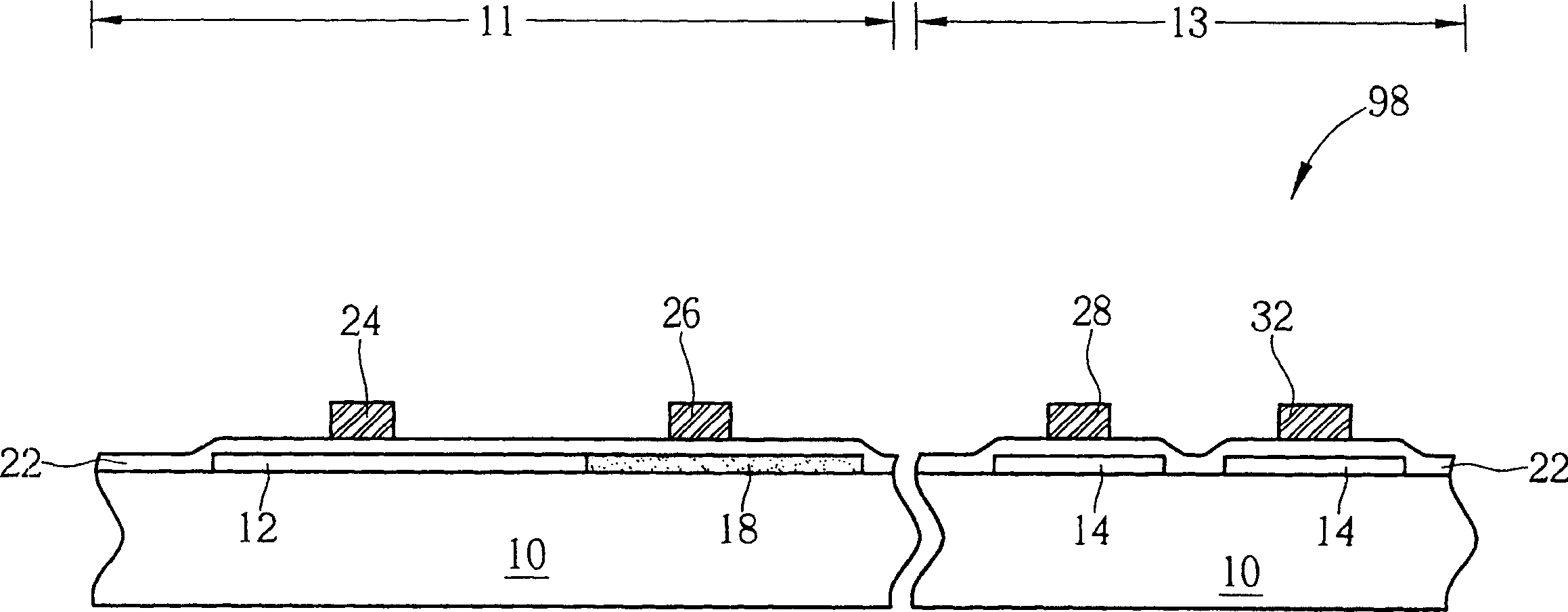

[0064] Please refer to Figure 9 to Figure 13 , Figure 9 to Figure 13 It is a schematic diagram of a method of manufacturing a low-temperature polysilicon thin film transistor liquid crystal display 174 in the first embodiment of the present invention. Such as Figure 9 As shown, the low-temperature polysilicon thin film transistor liquid crystal display of the present invention is manufactured on an insulating substrate 100. The insulating substrate 100 must be made of a light-transmitting material, usually a glass substrate or a quartz substrate, and the surface of the insulating substrate 100 includes a pixel. The array area 101 and a peripheral circuit area 103 .

[0065] In the present invention, an amorphous silicon film (not shown) is first formed on the surface of the insulating substrate 100 by a sputtering process or other processes, and then an excimer laser annealing process is performed to recrystallize the amorphous silicon film (not shown). into a polysilico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com