Transparent vanadate glass and method for making same

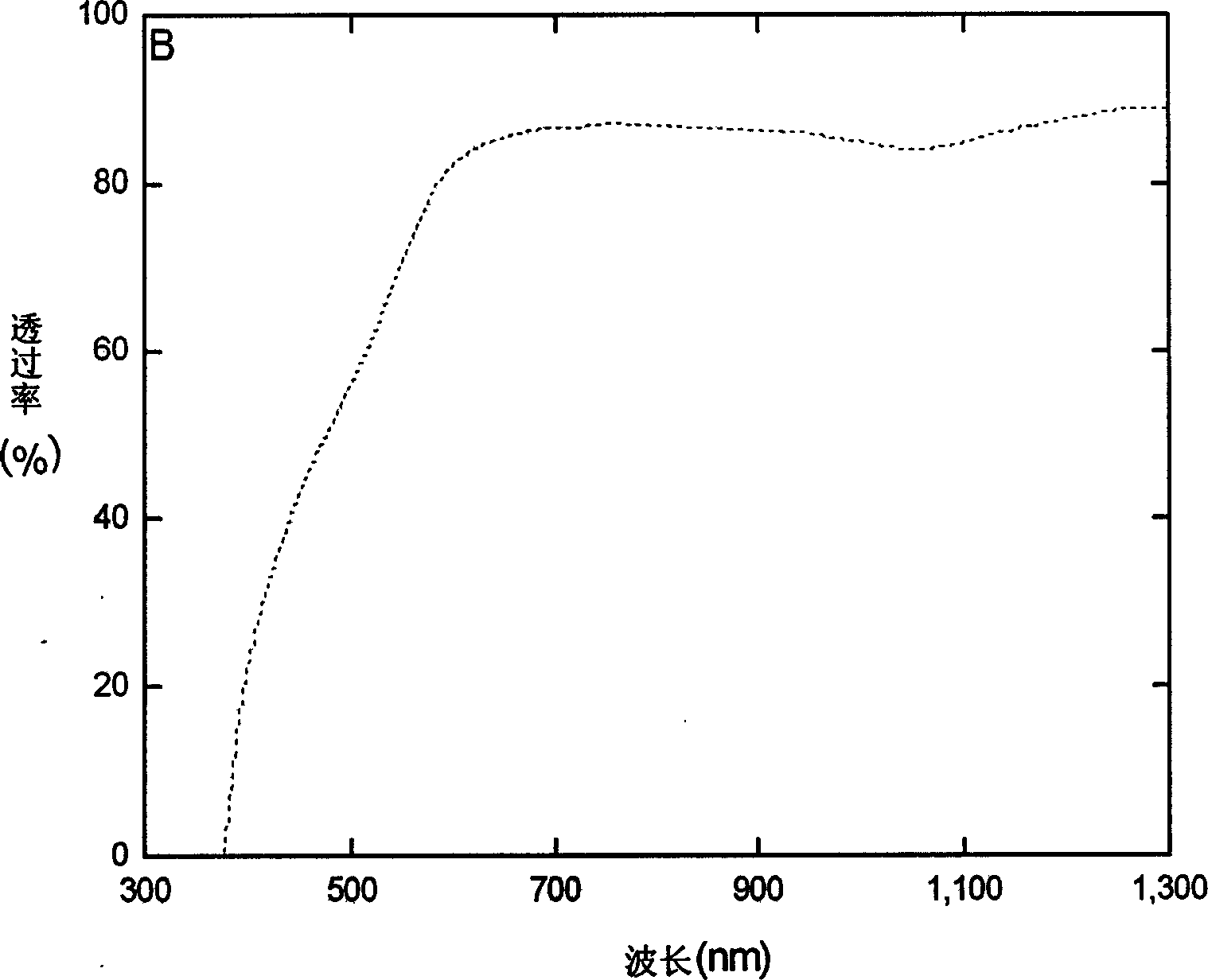

A technology of vanadate and glass, which is applied in the field of optical materials, can solve the problems that optical fibers cannot be drawn, it is difficult to grow, and the development of optical amplifiers is limited.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] According to the following main substance anion mass percentage V 2 o 5 : 22%; SiO 2 : 28%; Na 2 O: 5%; K 2 O: 10%; Cs 2 O: 5%; CaO: 12%, BaO: 18% Weigh the vanadate glass raw materials and mix them evenly, add them into a platinum crucible and melt at 1400°C for 2 hours under dry oxygen with a concentration of more than 99%. Pouring into shape. Cool in the annealing box from (Tg+10)°C to (Tg-100)°C at a rate of 1°C per hour, then take it out and cool it naturally. After cutting and polishing, the desired transparent vanadate glass can be obtained.

Embodiment 2

[0014] According to the following main substance anion mass percentage V 2 o 5 : 31%; SiO 2 : 19%; Na 2 O: 5%; K 2 O: 16%; CaO: 7%, BaO: 11%; SrO: 11%. Weigh the vanadate glass raw materials and mix them evenly, then add them to a platinum crucible and melt them at 1400°C under dry oxygen with a concentration of more than 99%. Hours, cast into molds. Cool in the annealing box from (Tg+10)°C to (Tg-100)°C at a rate of 5°C per hour, then take it out and cool it naturally. After cutting and polishing, the desired transparent vanadate glass can be obtained.

Embodiment 3

[0016] According to the following main substance anion mass percentage V 2 o 5 : 30%; SiO 2 : 20%; Na 2 O: 8%; K 2 O: 12%; Cs 2 O: 3%; CaO: 15%, BaO: 3%, SrO: 9%. Weigh the vanadate glass raw materials and mix them evenly, then add them to a platinum crucible and melt them at 1400°C under dry oxygen with a concentration of more than 99%. Hours, cast into molds. Cool in the annealing box from (Tg+10)°C to (Tg-100)°C at a rate of 1°C per hour, then take it out and cool it naturally. After cutting and polishing, the desired transparent vanadate glass can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com