Silicon nitride - boron nitride- silicon dioxide ceramic wave-transparent material and preparation process thereof

A technology of wave-transmitting material and silicon dioxide, which is applied in functional ceramic materials and special fields, can solve the problems of poor ablation performance, influence wave-transmitting performance, and large dielectric constant, and achieve good mechanical properties and dielectric properties. The method is scientific and reasonable, and the effect that meets the application requirements

Active Publication Date: 2005-01-26

SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

View PDF0 Cites 32 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

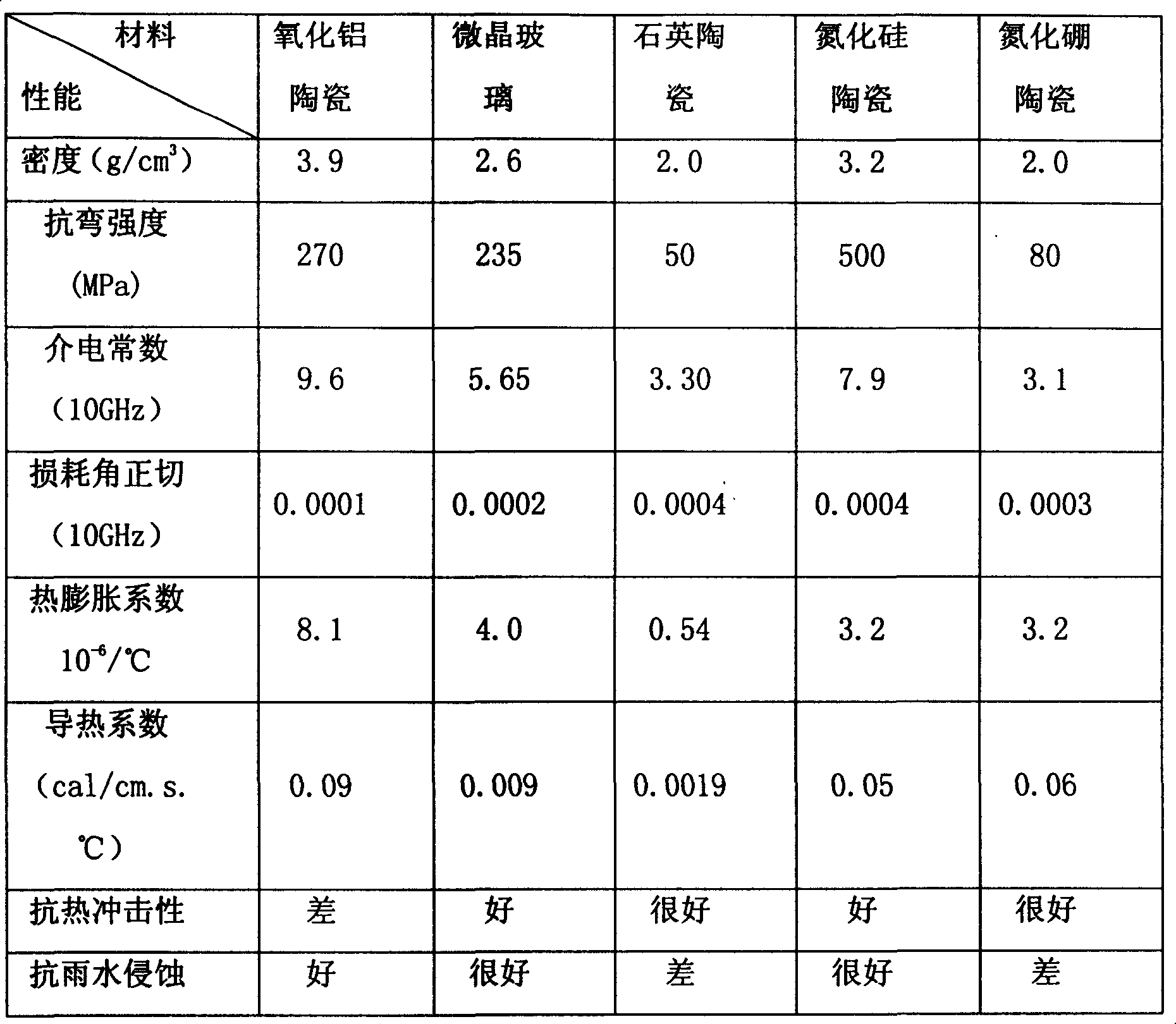

[0006] High-performance ceramic wave-transparent materials are one of the key directions of material research at home and abroad. In the past, the research focused on quartz ceramics. Due to the low mechanical and temperature resistance and poor ablation performance of quartz ceramics, its application has been greatly affected. limits

In recent years, research on silicon nitride ceramics and boron nitride ceramic materials has been mainly carried out internationally. Since silicon nitride ceramic materials were mainly used as structural ceramics in the past, their mechanics, temperature resistance and ablation resistance are in the material Medium is the best, but its dielectric constant is large, which affects its wave-transmitting performance; boron nitride ceramics have a low dielectric constant, and their stability is very good, but the mechanical properties of boron nitride ceramics are poor, And easy to deliquescence in the air

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0029] density

Embodiment 2

[0031] density

[0032] Others are with embodiment 1.

Embodiment 3

[0034] density

[0035] Others are with embodiment 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Login to View More

Abstract

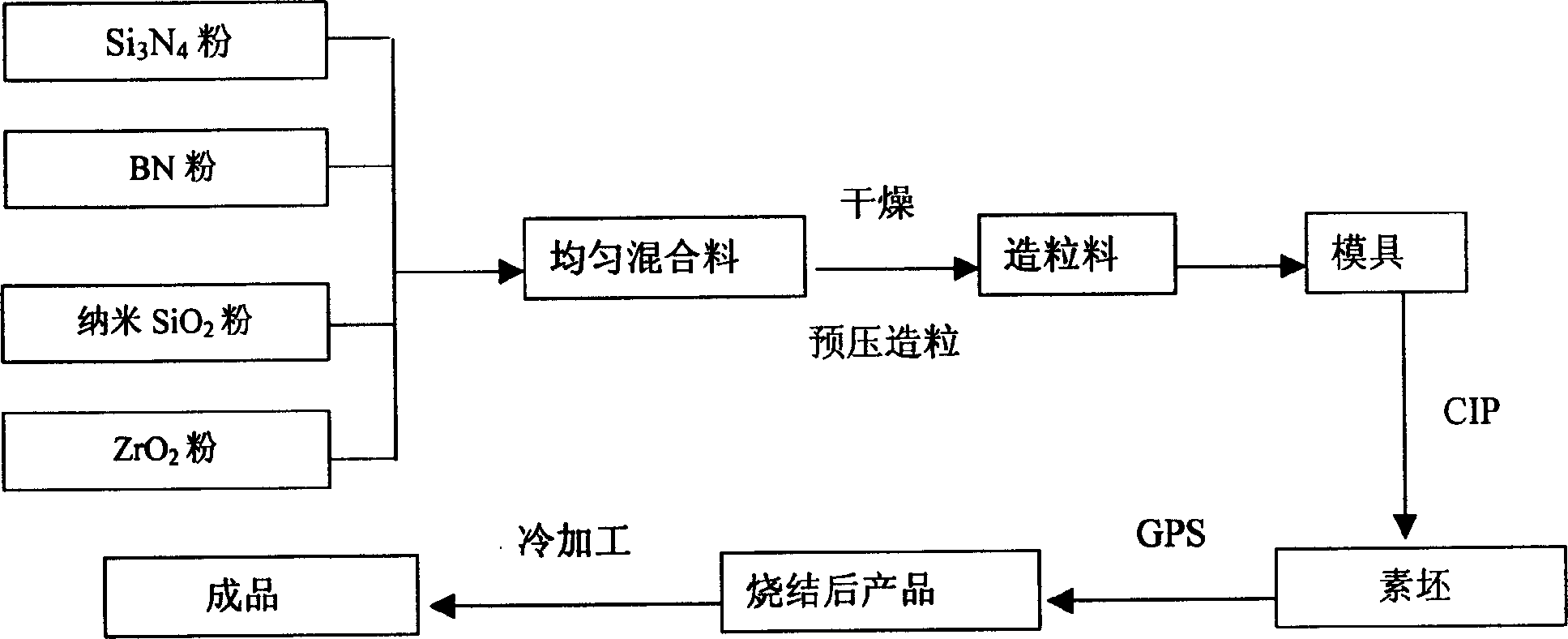

The invention relates to a ceramic wave-transmitting material and preparing method thereof, wherein the material is prepared from sub-micron high purity silicon nitride, boron nitride, zirconium dioxide and nano silica flour through batching, homogeneously mixing by means of supersonic wave and chemical dispersion method, forming through cold isostatic compaction method, and high-sintering in nitrogen atmosphere.

Description

technical field [0001] The invention relates to a ceramic wave-transparent material and a preparation method thereof, and belongs to the technical field of special and functional ceramic materials. Background technique [0002] The performance of the radome depends on the selected material. In the guidance system, the transmission efficiency and aiming error of the radome are very sensitive to the dielectric properties of the material and their relationship with temperature, frequency, etc., and the material is required to have a low dielectric constant ( ε<10) and dielectric loss, and the dielectric properties do not change significantly with temperature and frequency (such as temperature rise of 100°C, ε change<1%). The high Mach number of the missile makes the instantaneous heating rate of the radome as high as 120°C / S or more. Therefore, when the temperature is raised, the molecular structure of the material is required to be stable, and the material properties (su...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B35/14C04B35/48C04B35/583C04B35/584C04B35/622

Inventor 张伟儒王重海刘子峰高芳刘建范景林徐鸿照

Owner SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com