Sandwich construction fiber reinforced elastic body pipe compensator and forming method thereof

A pipeline compensator and fiber-reinforced technology, which is applied in expansion compensation devices for pipelines, pipe components, pipes/pipe joints/fittings, etc., can solve the problems of reduced high temperature resistance, environmental hazards, and the actual life of solid particles is lower than the design Value and other issues, to achieve the effect of improved fatigue life and resistance to solid particle wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

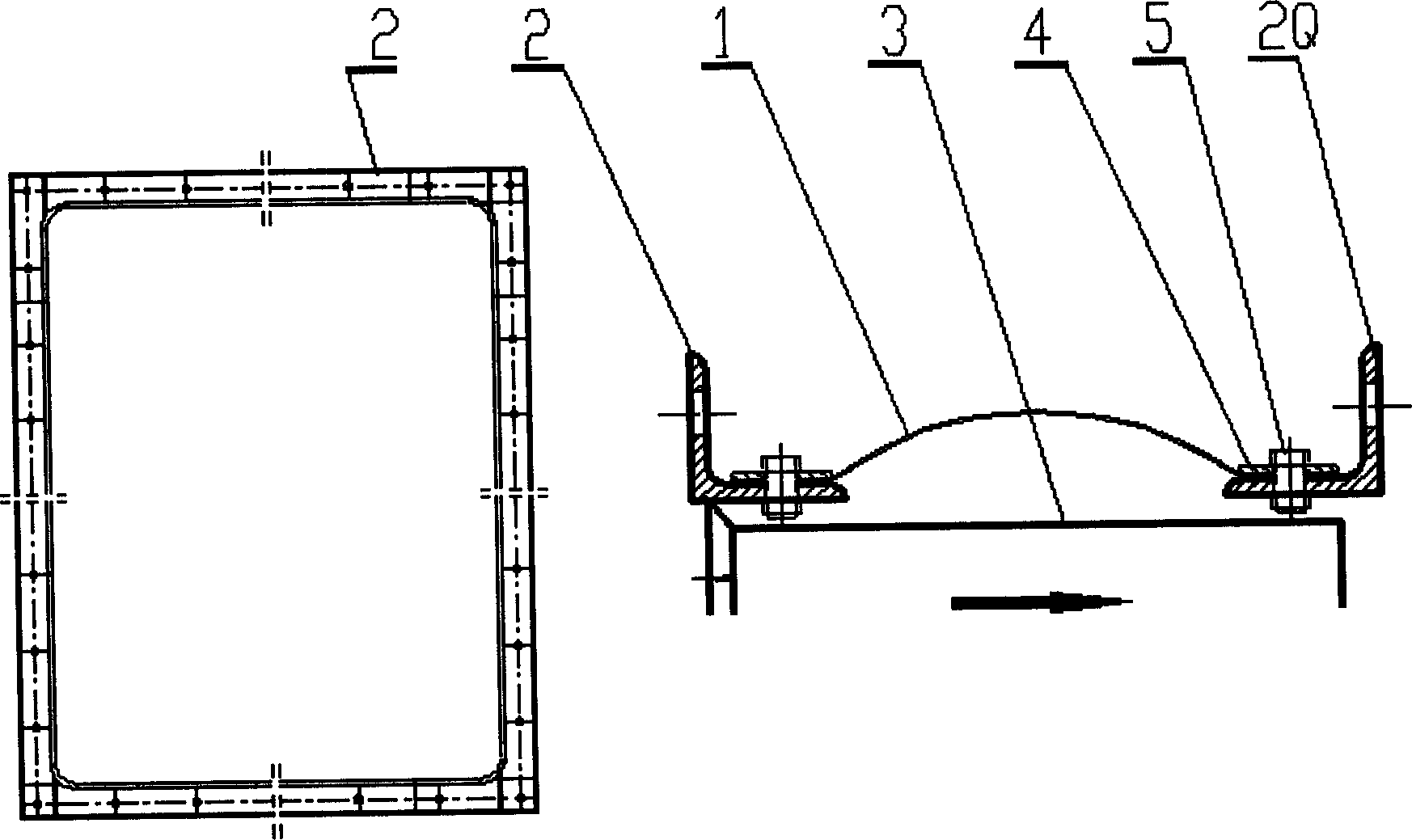

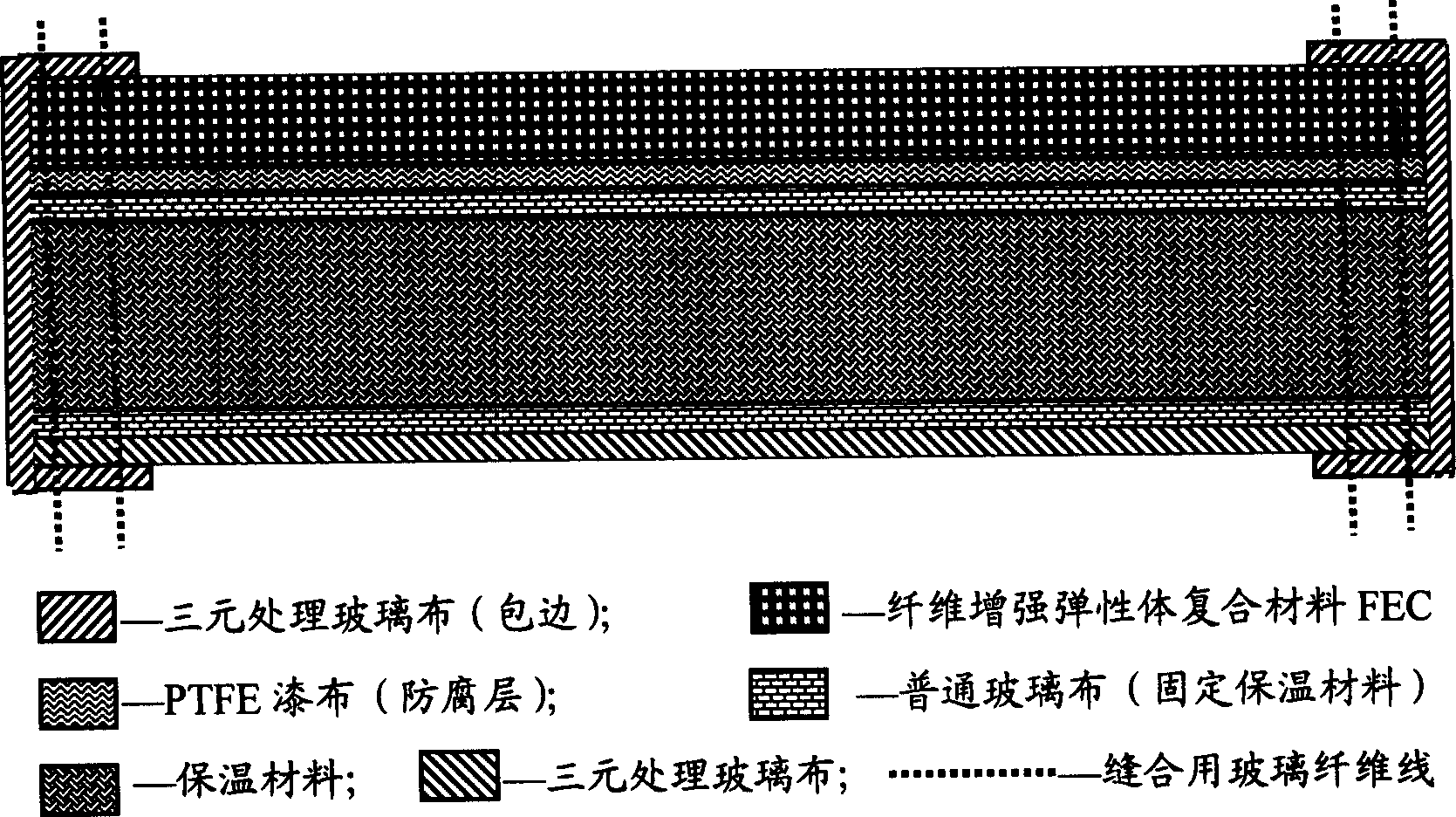

[0025] Example 1: The working medium of the compensator is flue gas, its inner diameter is 430mm×1980mm, the axial installation length is 400mm, the compensation amount is ≤10mm; the design pressure P≤1000Pa, and the temperature t≤150°C. See figure 1 , The multi-layer structure fiber-reinforced elastomer pipeline compensator of this embodiment is installed by two flanges 2 fixedly connected to the two ends of the compensation pipe section 1, and one end of the two flanges 2 The diversion sleeve 3 in the compensation pipe section 1 is formed. The pipe wall structure of the compensation pipe section 1 is: the outer layer is a fiber reinforced elastomer composite material (FEC), and the specific form of the material is a fiber cloth reinforced by a mixture of non-asbestos fiber and steel wire. Rubber; the second layer is an anti-corrosion layer made of polytetrafluoroethylene (PTFE) varnished cloth; the third layer is an insulating layer made of block glass wool or ceramic wool wrap...

Embodiment 2

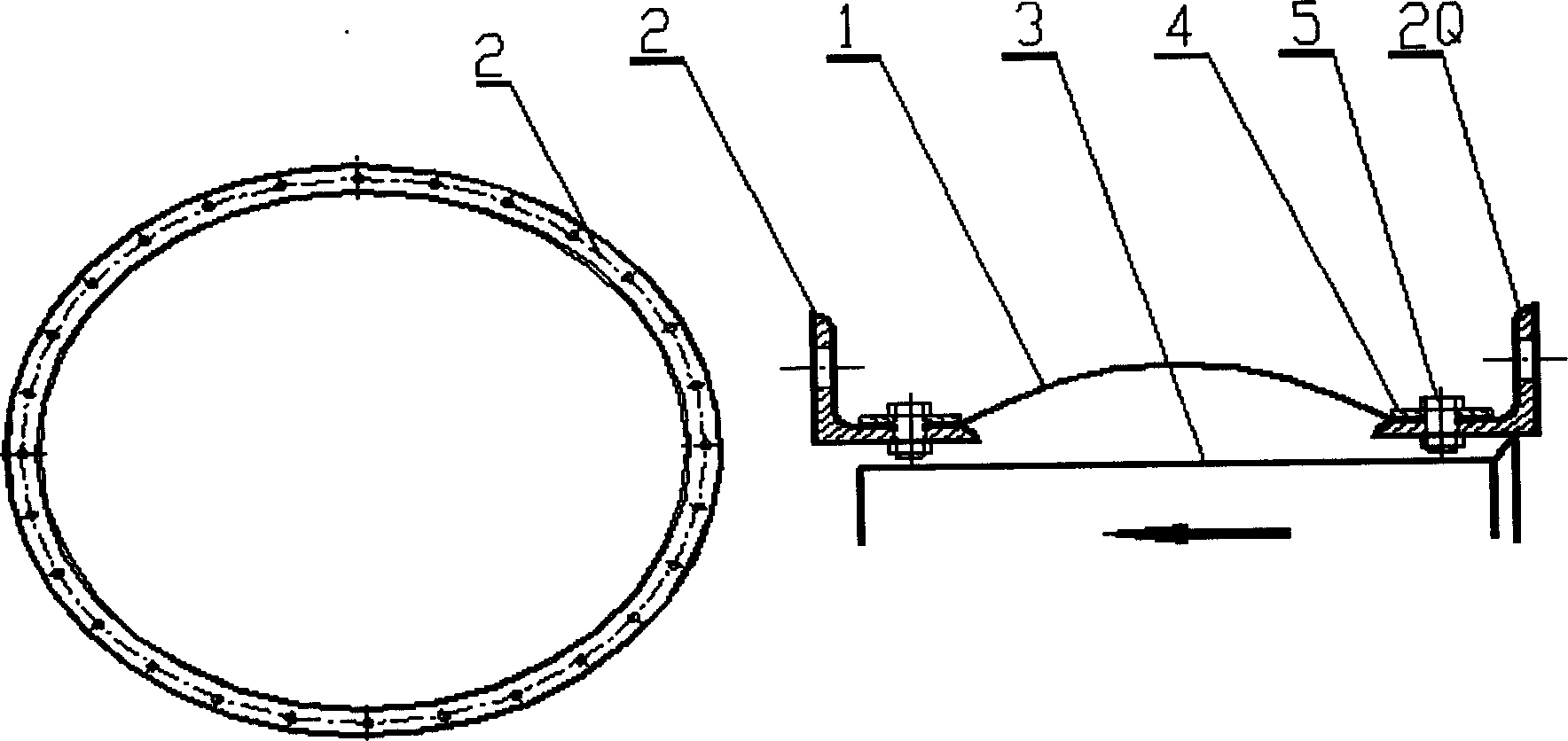

[0034] Example 2: see figure 2 This embodiment is basically the same as the above embodiment, the difference is that the compensation tube section 1 is a circular tube, the manufacturing process of this embodiment is basically the same as the above embodiment, and the multilayer structure composite material is also basically the same, see Figure 6 . The working medium of the compensator of this embodiment is flue gas, the inner diameter is 2200mm, the axial installation length is 400mm, the compensation amount is ≤10mm, the design pressure P≤1000Pa, and the temperature t≤300°C.

[0035] In the multi-layer fiber reinforced rubber composite material, the rubber is fluorine rubber, and the reinforcement is a woven cloth of glass fiber and stainless steel wire (10% by volume). The fiber-reinforced fluororubber composite material is prepared according to the traditional process. The formula and vulcanization conditions of fluorine rubber are shown in Table 2:

[0036] Table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com