Polymeric electrochromic devices

An electrochromic, polymer technology, used in transportation and packaging, synthetic resin layered products, instruments, etc., can solve problems such as poor conductivity of coating films, film ruptures, and plastic substrates that cannot withstand high deposition temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

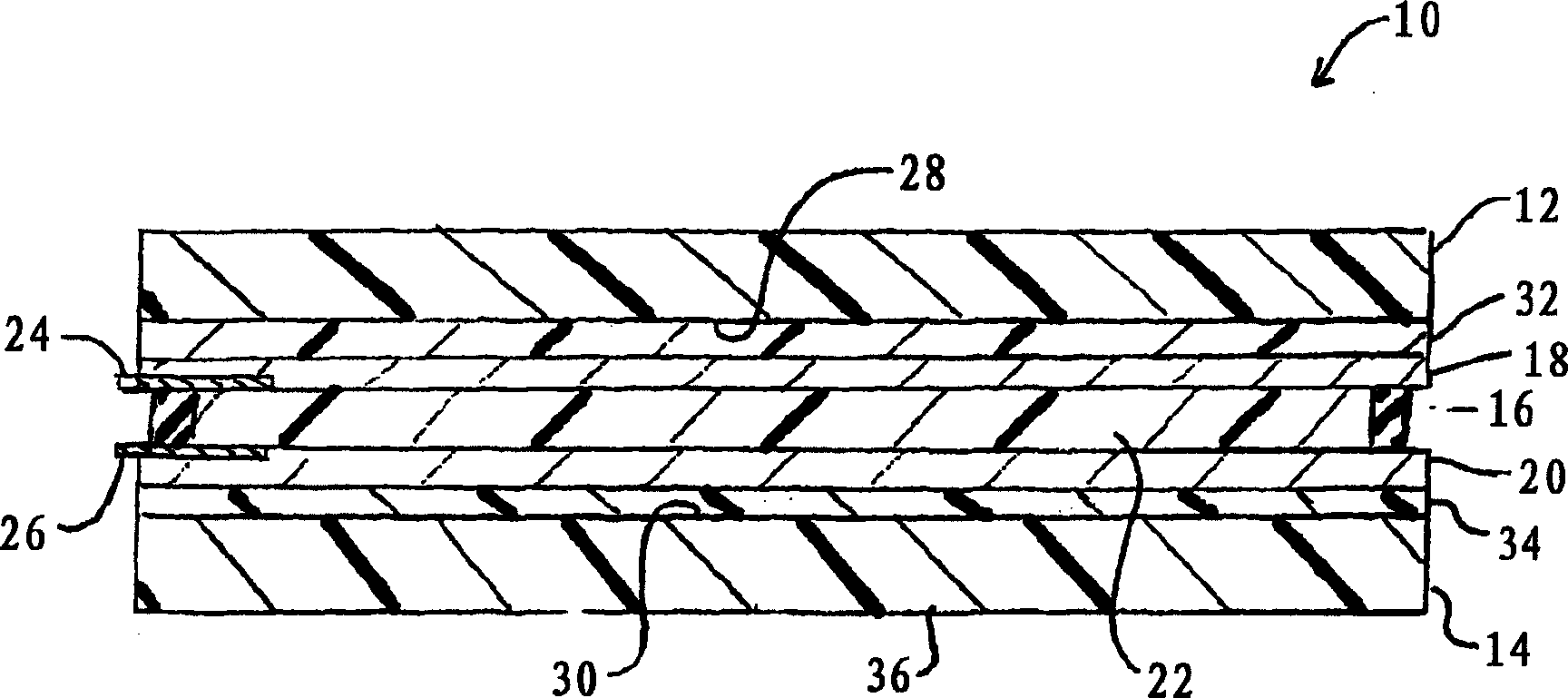

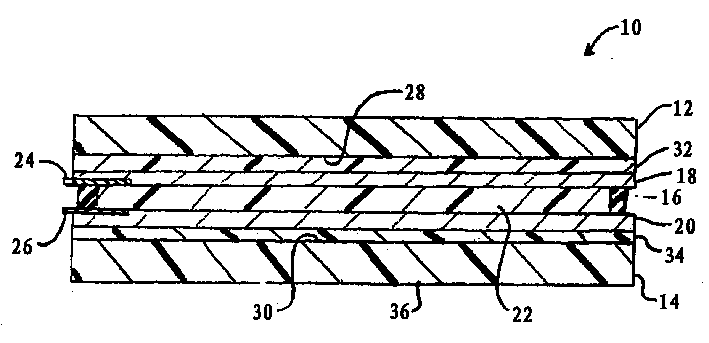

Image

Examples

example 1

[0066] The primer composition was prepared as follows:

[0067] The cyanoethylacrylate / acrylic acid oligomer was prepared at 25% solids in cyclohexane. The crosslinker 2-(3,4-epoxycyclohexyl-5,5-spiro-3,4-epoxy)cyclohexane-idexane is added to react with at least 50% of the carboxylic acid groups. Dibutyl dilaurate was added as catalyst.

[0068] The prepared solution was applied to the surface of an elongated acrylic plastic substrate and cured at a temperature of 190°F (88°C). A plastic substrate including a primer composition on its surface was placed in a vacuum chamber, and an indium tin oxide (ITO) coating was sputter-deposited from a metal cathode on the surface of the primer layer to a resistance value of 10Ω / □.

[0069] This process is repeated for the second substrate.

[0070] Electrochromic devices were fabricated from two elongated acrylic plastic substrates coated with an indium tin oxide coating. More specifically, a solution of xylene viologen perchlorate, d...

example 2

[0073] A primer composition was prepared using 0.1 equivalents of carbonate diol, KM-1667 solids from Stahl Corp, 0.9 equivalents of trimethylolpropane, and 1.0 equivalents of solids polyisocyanate Mondur MR from Bayer Corp. The final solution was a 10% solids solution in diacetone alcohol.

[0074] The freshly prepared solution was applied to one surface of two substrates made of solid Lexan® polycarbonate sold by G.E.Corp and cured at 230°F (110°C) for 4 hours. The composite substrates were placed in a vacuum chamber, and then a conductive coating of ITO was sputter-deposited from a metal cathode on top of the primer composition coating on each substrate, with sheet resistance values in the range of 3-10Ω / □.

[0075] The electrochromic device described in Example 1 was constructed using two coated substrates. When a voltage of 1.0 V was applied, the transmittance of the device switched from 67% to 0.2%. Electrochromic devices were stored for 2 months before testing. Alt...

example 3

[0077] Primer compositions were prepared at 25% solids in cyclohexanone for elongated acrylic and Plexglas(R) acrylic flakes composed of methyl methacrylate / acrylic copolymer. Cycloaliphatic diepoxide is added to react at least 25% of the carboxylic acid groups. The final solution was 10% solids.

[0078] As-made primer sets are applied to stretched acrylic and Plexglas acrylic sheets and cured at temperatures below 195°F (91°C). By magnetron sputtering from the metal cathode, an ITO conductive coating was applied to each surface with the primer, and the sheet resistance value of the ITO conductive coating was 3Ω / □.

[0079] Electrochromic devices such as those described in Example 1 were prepared from freshly prepared elongated acrylic substrates and Plexglas substrates. The transmittance of the device switched from 62% to 0.1% when a voltage of 1V was applied to the conductive coating. Electrochromic devices were stored for 3 months before testing. Although the electroch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com