Fruit-vegetable fresh-retaining film, and its production method and equipment

A technology of fruit and vegetable fresh-keeping and fresh-keeping materials, which is applied in food preservation, food science, application, etc. It can solve the problems of unstable product quality, lack of antibacterial, slow manual coating operation, etc., and achieve superior product performance and improved work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

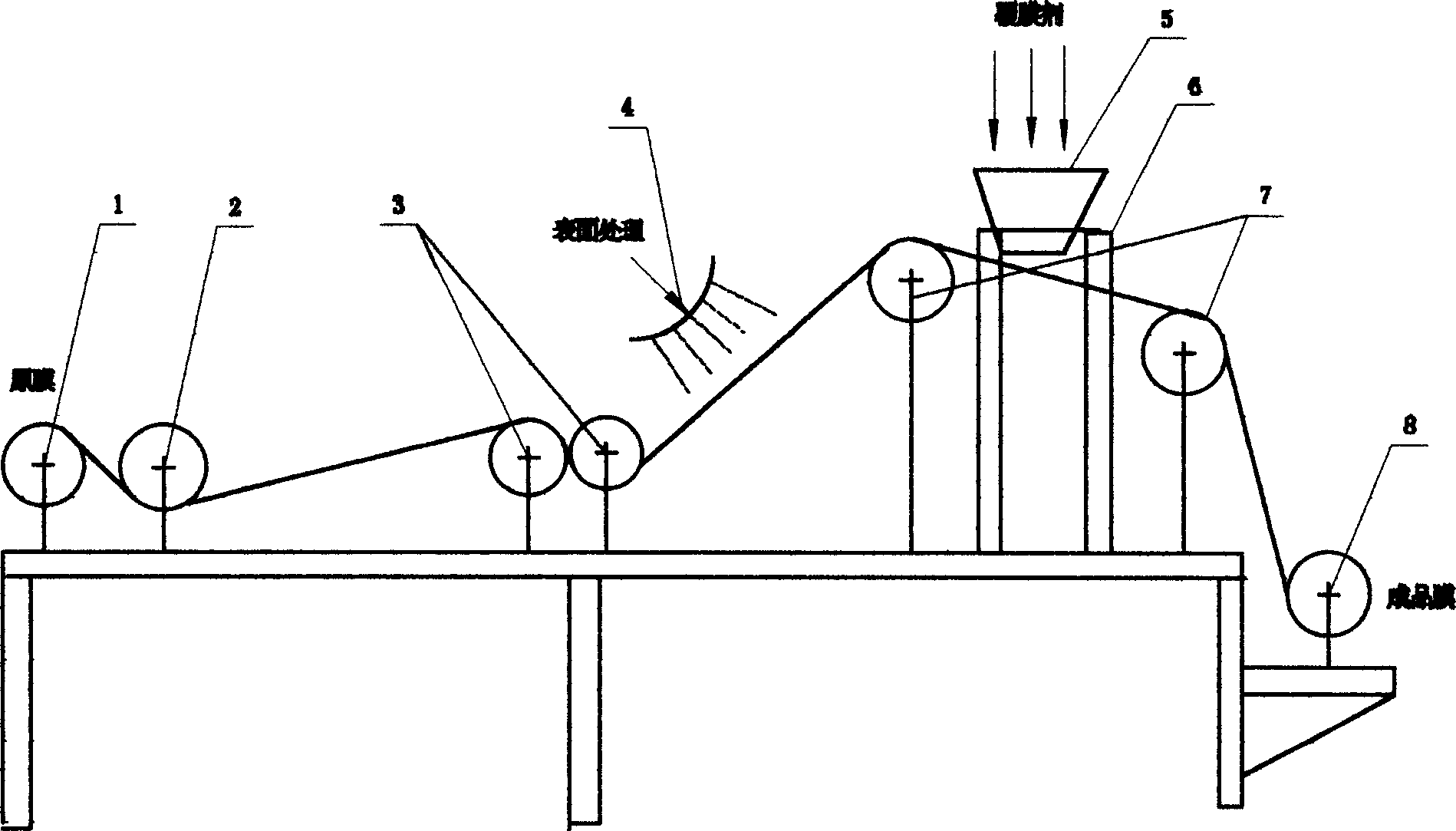

Image

Examples

Embodiment 1

[0026] Embodiment 1: get thickness and be 0.005mm polyethylene film 1000 square meters, modified starch 20kg, lecithin 10g, sucrose ester 15g, citric acid 5 grams, carbendazim 10g, after punching on the preservative film production equipment, through The sucrose ester aqueous solution is used for surface treatment, and the mixture of modified starch and lecithin is evenly coated on the surface of the treated film to obtain a fresh-keeping film with fruit freshness preservation function, and the storage time of mangoes packed with the fresh-keeping film can be extended by more than 50%.

Embodiment 2

[0027] Embodiment 2: get thickness and be 1000 square meters of high and low pressure polyethylene (blend) film of 0.005mm, water-based polyacrylate adhesive 10kg, carboxymethyl cellulose 5kg, dimethyl fumarate 10g, sucrose 5kg, silica bath soil 3kg, after carrying out surface treatment through aqueous polyacrylate solution on the preservative film production equipment, the mixture of carboxymethyl cellulose, dimethyl fumarate and silicon bath soil is evenly coated on the film surface that has been processed, obtains The fresh-keeping film has the function of keeping fruit fresh, and the storage time of citrus packed with the fresh-keeping film can be extended by more than 50%.

Embodiment 3

[0028] Embodiment 3: getting thickness is 1000 square meters of high-pressure polyethylene film of 0.01mm, polyvinyl alcohol starch glue 15kg, chitosan and its modified substance 1.5kg, green fresh element 5g, ascorbic acid 1kg, oxalic acid 0.5kg, in fresh-keeping After the surface physical treatment is carried out on the film production equipment, it is first coated with polyvinyl alcohol starch glue, and then the remaining substances are made into a solution and evenly coated on the surface of the treated film to obtain a fresh-keeping film with fruit freshness preservation. The storage time of litchi packed in plastic wrap can be extended by more than 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com