Superblack wool fabric having nano-structure fiber surface and its preparing method

A fiber surface and nanostructure technology, applied in ultrasonic/sonic fiber treatment, dyeing, textiles and papermaking, etc., can solve the problems of inability to obtain ultra-black fabrics, limited deepening effect, rising cost, etc., and achieve excellent ultra-black effect , Improving the diffusion ability and reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

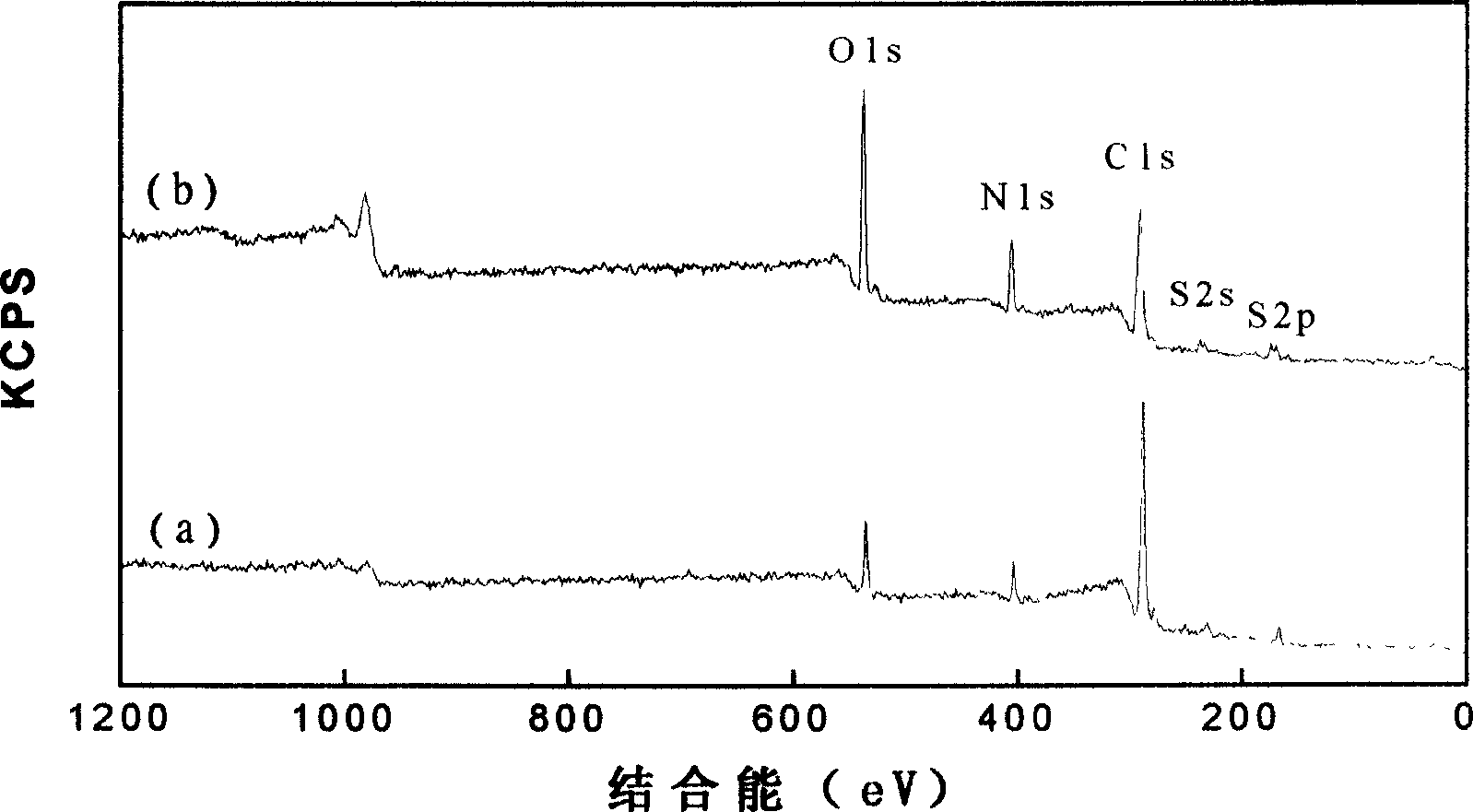

[0029] Put the wool fabric into the low-temperature plasma reaction chamber, vacuumize, and when the pressure in the reaction chamber reaches 4Pa, start to introduce air to balance the vacuum degree in the reaction chamber at 26Pa, then start discharging, and perform low-temperature plasma treatment for 30 minutes with 200W power The discharge treatment of the nanometer-scale concave-convex structure is formed on the surface of the fiber, and the diameter or width of the concave part is 30-200nm.

[0030] The above-mentioned wool fabric having a nano-scale concave-convex structure on the surface was dyed according to the following conditions.

[0031] Dye Recipe % (o.w.f. to fabric weight)

[0032] Acid Media Black T 2

[0033] Pingping plus 0.3

[0034] Acetic acid 2

[0035] pH 4~4.5

[0036] Red alum 1.20

[0037] Bath ratio 1:20

[0038] Process curve: such as Image 6 shown.

[0039] The ultra-black wool fabric with nano-scale concavo-convex structure on the fiber ...

Embodiment 2

[0041] Put the wool fabric into the low-temperature plasma reaction chamber, vacuumize it, and when the pressure in the reaction chamber reaches 7Pa, start to introduce oxygen to balance the vacuum degree in the reaction chamber at 160Pa, then start discharging, and perform low-temperature plasma treatment for 60 minutes with 50W power discharge treatment. Except that Acid Media Black 2B was used instead of Acid Media Black T, other dyeing conditions were the same as in Example 1. The ultra-black wool fabric with nano-scale concavo-convex structure on the fiber surface is obtained, and the width of the concavity is 30-200nm.

Embodiment 3

[0043] Put the woolen fabric into the low-temperature plasma reaction chamber, vacuumize it, and when the pressure in the reaction chamber reaches 7Pa, start to feed helium / nitrogen (volume ratio is 6 / 4) to balance the vacuum degree in the reaction chamber at 67Pa, then start discharging, and carry out For low-temperature plasma treatment, discharge treatment was performed for 1 minute with 300W power. The other dyeing conditions were the same as in Example 1 except that acid media black PV was used instead of acid media black T. The ultra-black wool fabric with nano-scale concavo-convex structure on the fiber surface is obtained, and the width of the concavity is 30-200nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge power | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com