High temperature proton exchange film fuel cell membrane electrode and its preparing method

A fuel cell membrane and proton exchange membrane technology, applied in solid electrolyte fuel cells, fuel cells, battery electrodes, etc., can solve the problems of high contact resistance, affecting proton transmission, etc., and achieve good high-temperature water retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

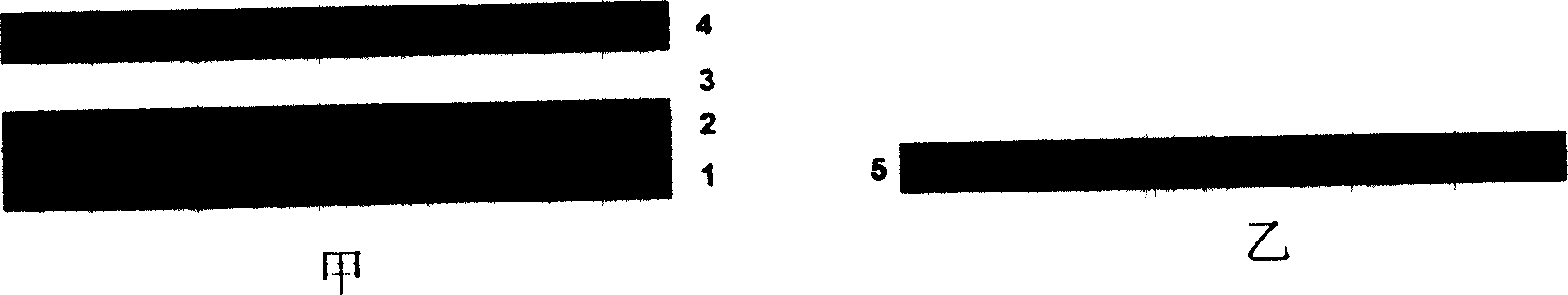

Method used

Image

Examples

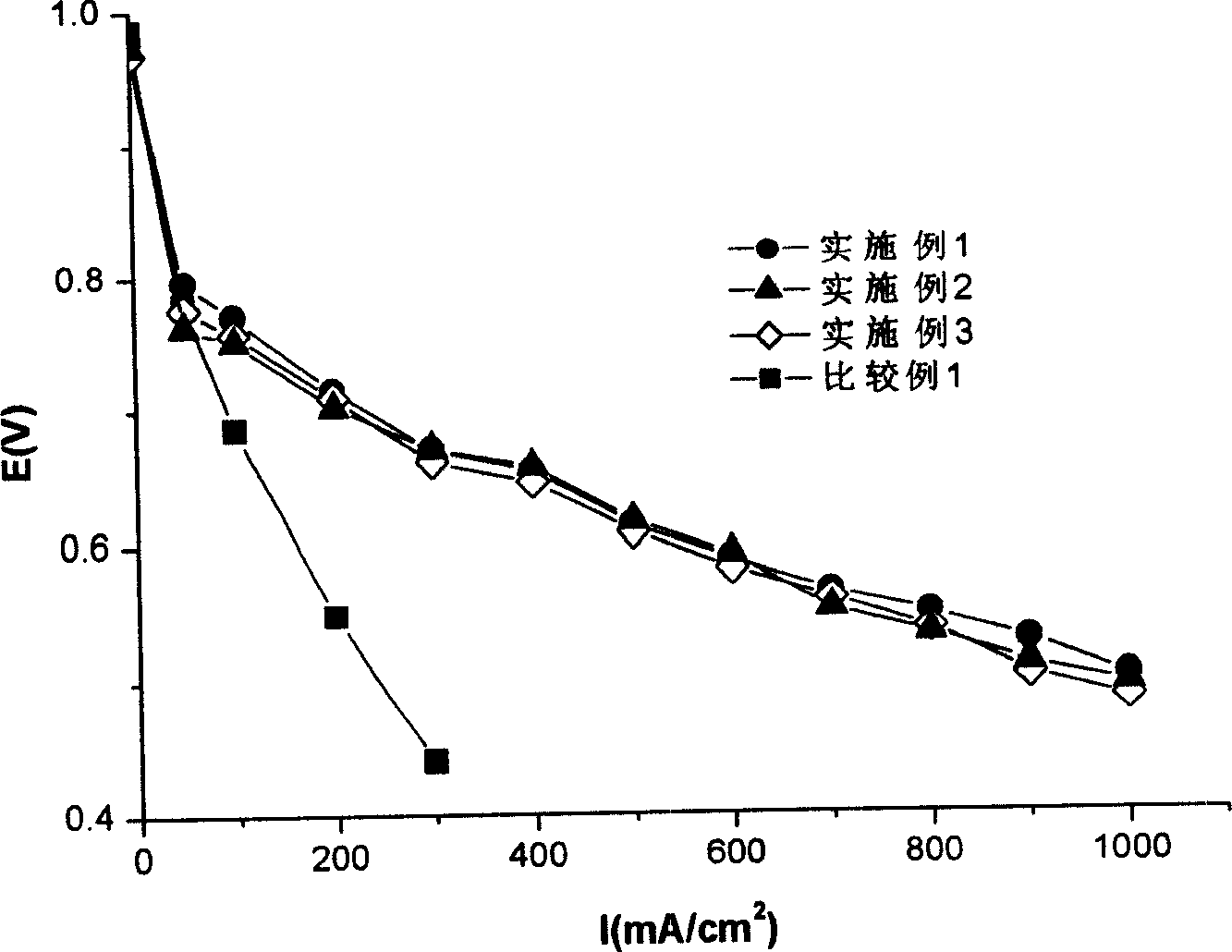

Embodiment 1

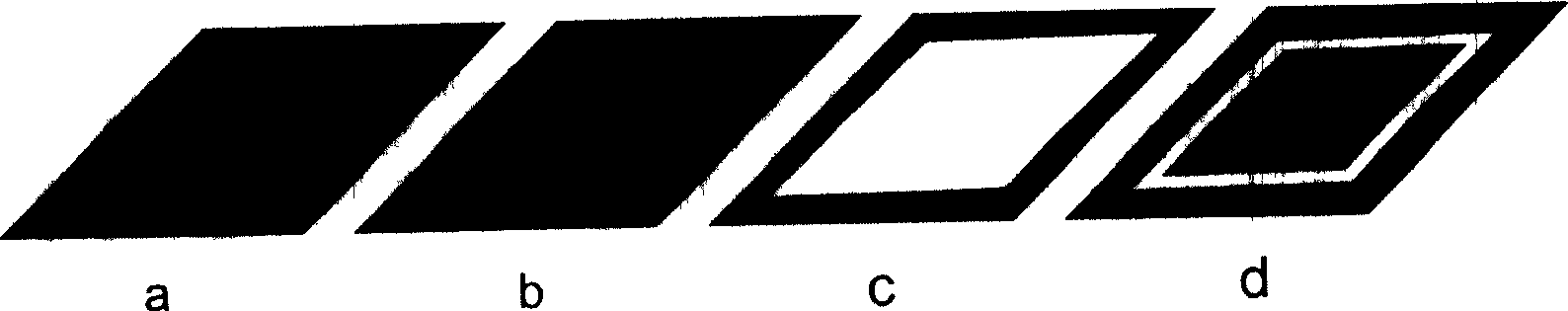

[0043] Preparation of the membrane electrode main unit. A layer of hydrophobic layer (sublayer) composed of conductive carbon black and polytetrafluoroethylene (PTFE) particles was evenly compounded on the surface of the hydrophobically treated carbon paper, and calcined at 350°C for 20min to obtain a gas diffusion layer. Prepare catalyst slurry according to carbon-supported platinum catalyst: Nafion® resin: isopropanol is a mass ratio of 3: 1: 300, get part of the slurry, and print to the second hydrophobic layer (sublayer) of the gas diffusion layer by screen printing side, vacuum-dried for 1-10 hours, so that the catalyst layer is hardened on the surface of the gas diffusion layer. Mix 33ml of tetraethyl orthosilicate and 300ml of absolute ethanol evenly, then dropwise add a mixture of 240ml of absolute ethanol and 60ml of 0.3M hydrochloric acid, and keep stirring at a temperature of 50°C for 12h to obtain nano-SiO 2 of aqueous solution. nano-SiO 2 The aqueous solution i...

Embodiment 2

[0046] The preparation method of the membrane electrode main unit and the single cell assembly and test conditions are the same as in Example 1, except that the water-retaining layer is mainly composed of nano-TiO 2 And Nafion resin composition. Its preparation method is as follows: add 25ml of glacial acetic acid to 100ml of tetrabutyl titanate, mix well, slowly pour into 600ml of water under vigorous stirring, continue stirring for 3h, after hydrolysis is complete, add 10ml of 70wt% nitric acid, After heating to 80 °C, continue to stir for 2 h to prepare nano-TiO 2 colloidal solution. Then the nano-TiO 2 The aqueous solution was mixed with isopropanol and 5wt% Nafion solution, and ultrasonicated for 30 min. The volume ratio of isopropanol to 5wt% Nafion solution is 2: 1; if TiO 2 and the mass of Nafion resin is 100%, then TiO 2 The proportion is 10wt%. The average thickness of the prepared cathode catalyst layer (the side with the hydrophobic layer) is 4 μm, and the av...

Embodiment 3

[0048] The preparation method of the membrane electrode main unit and the single cell assembly and test conditions are the same as in Example 1, except that the water-retaining layer is mainly composed of nano-Zr(HPO 4 ) 2 And Nafion resin composition. Its preparation method is as follows: take 1.5M zirconium oxychloride (ZrOCl 2 ) solution 100ml and the dehydrated alcohol of 400ml are evenly mixed, then dropwise add the mixed solution of the dehydrated alcohol of 400ml and 20ml 1M phosphoric acid, continue to stir 24h under the temperature of 80 ℃, obtain containing nanometer Zr (HPO 4 ) 2 of aqueous solution. Then Zr(HPO 4 ) 2 The aqueous solution was mixed with isopropanol and 5wt% Nafion solution, and ultrasonicated for 10 min. The volume ratio of Virahol and 5wt% Nafion solution is 2: 1; if Zr(HPO 4 ) 2 And the quality of Nafion resin is 100%, then Zr(HPO 4 ) 2The proportion is 10wt%. The average thickness of the prepared cathode catalyst layer (the side with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com