Composite proton exchange membrane for high-temp proton exchange membrane fuel cell and preparation method

A proton exchange membrane, fuel cell technology, applied in solid electrolyte fuel cells, fuel cells, fuel cell parts and other directions, can solve the problems of gas channeling, large increase, the impact of fuel cell durability, and achieve good high temperature water retention performance , the effect of good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

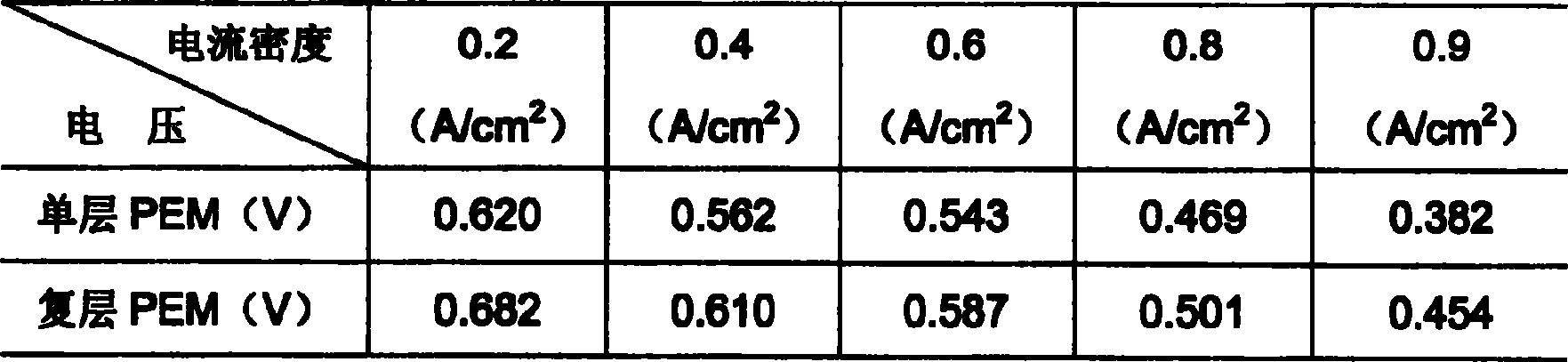

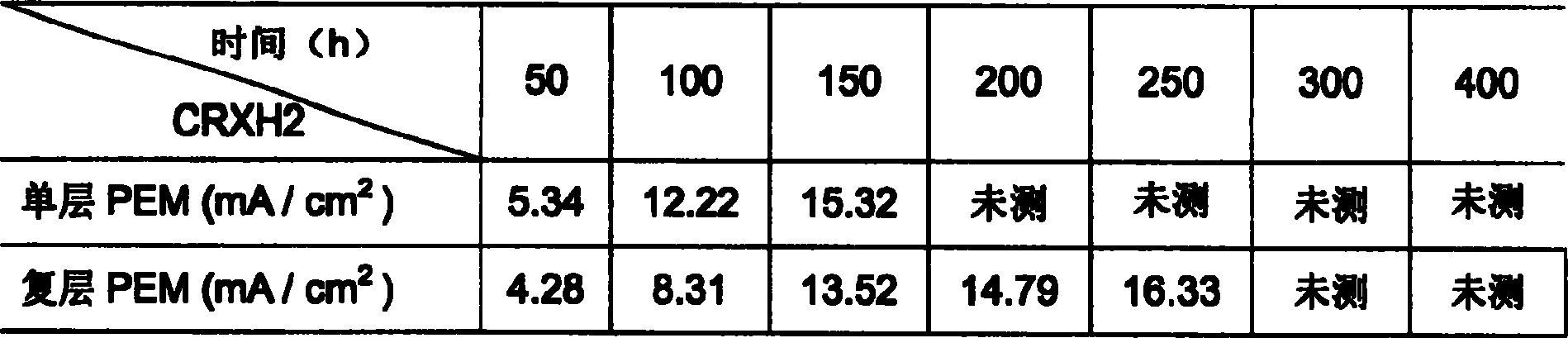

[0031] Preparation of single-layer porous polymer reinforced composite proton exchange membrane: select expanded polytetrafluoroethylene microporous membrane with an average thickness of 3 μm, an average pore diameter of 0.2 μm and a porosity of 85%, immerse in isopropanol for cleaning and pre-swelling treatment After taking it out and drying it, clamp the film with a thin aluminum frame; mix 33ml of tetraethyl orthosilicate with 300ml of absolute ethanol, then add dropwise 240ml of absolute ethanol and 60ml of hydrochloric acid with a molar concentration of 0.3M solution, continuously stirred at 50°C for 12h to obtain nano-SiO 2 aqueous solution; according to SiO 2 : Nafion The mass ratio of the resin to 1:10 will be nano-SiO 2 Aqueous solution and 5wt% Nafion Solution (DuPont company product) mixed, ultrasonic 30min, prepared SiO 2 with Nafion solution; the porous polymer membrane was immersed in SiO 2 After 20 minutes, take out the membrane, place it horizontally o...

Embodiment 2

[0039] Single-layer PEM is basically the same as Example 1, except that the expanded polytetrafluoroethylene microporous membrane used has an average thickness of 5 μm, an average pore diameter of 0.5 μm, and a porosity of more than 80%; The previous step was repeated 3 times for the membrane. The preparation method of the multilayer PEM is basically the same as that of Example 1, except that the number of layers of the porous polymer-reinforced composite proton exchange membrane in the stack is 3, and the hot pressing pressure is 2.5 MPa. The experimental methods of film stretching, single cell performance and accelerated life test are the same as those in Example 1. After measurement, the tensile strengths of expanded polytetrafluoroethylene microporous membrane, single-layer PEM and multi-layer PEM are 15MPa, 19MPa, and 37MPa, respectively. Table 3 and Table 4 respectively show the battery performance test and life acceleration test results of the composite membrane. It is...

Embodiment 3

[0045] The single-layer PEM is basically the same as in Example 1, except that the expanded polytetrafluoroethylene microporous membrane used has an average thickness of 10 μm, an average pore diameter of 0.5 μm, and a porosity greater than 80%; Repeat the previous step 4 times. The preparation method of the multilayer PEM is basically the same as that of Example 1, except that the number of layers of the porous polymer-reinforced composite proton exchange membrane in the stack is 2, and the hot pressing pressure is 5 MPa. The experimental methods of film stretching, single cell performance and accelerated life test are the same as those in Example 1. The tensile strengths of expanded polytetrafluoroethylene microporous membrane, single-layer PEM and multi-layer PEM are 22MPa, 28MPa and 47MPa respectively. Table 5 and Table 6 respectively show the results of the battery performance test and life acceleration test of the composite proton exchange membrane. It is not difficult ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com