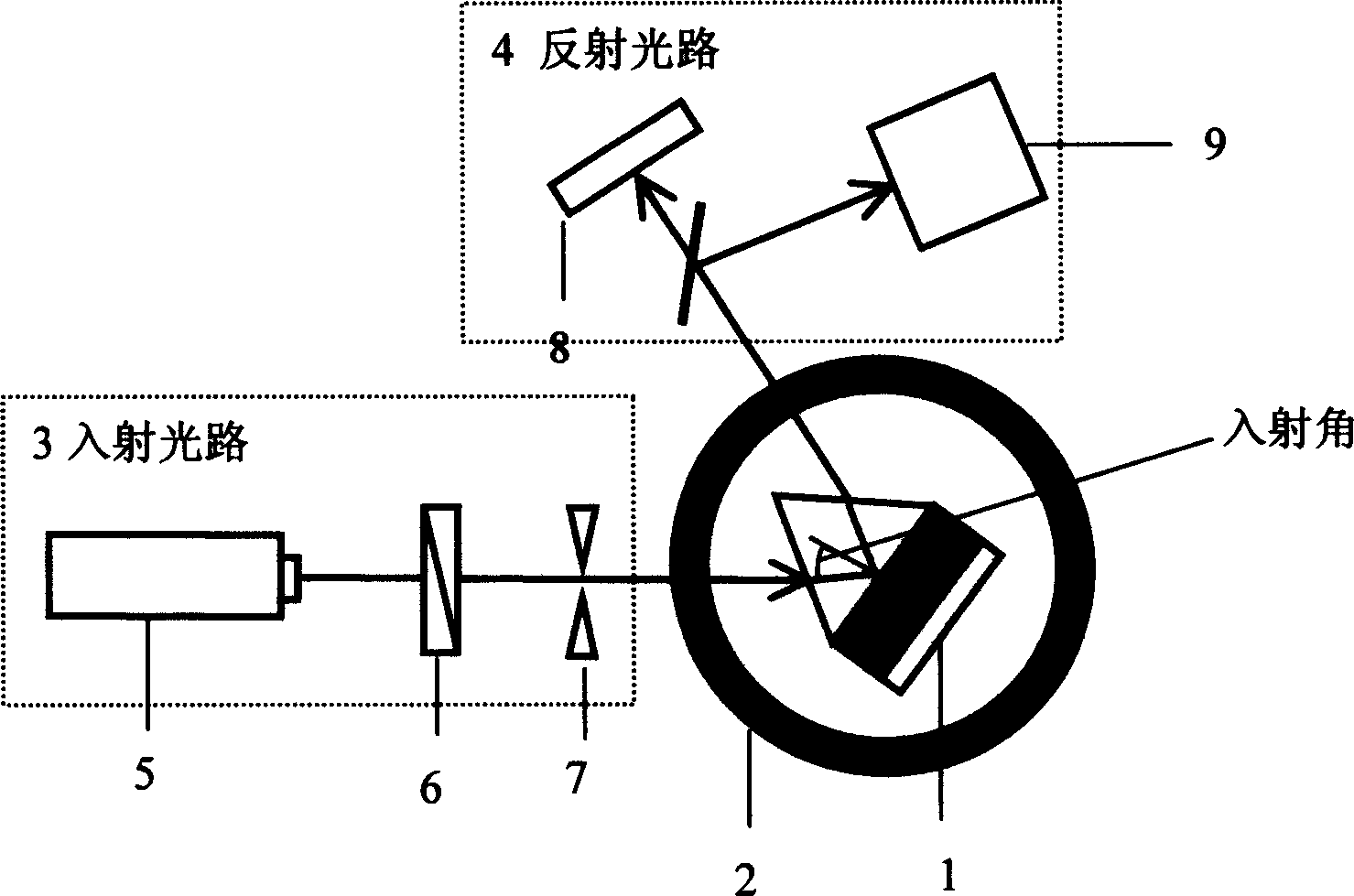

Apparatus and method for calibrating spectrum by prism/waveguide coupling unit

A coupling unit and spectral shaping technology, applied in the field of laser applications, can solve the problems of phase distortion, high cost, laser side effects, etc., and achieve the effects of strong shaping ability, easy production and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

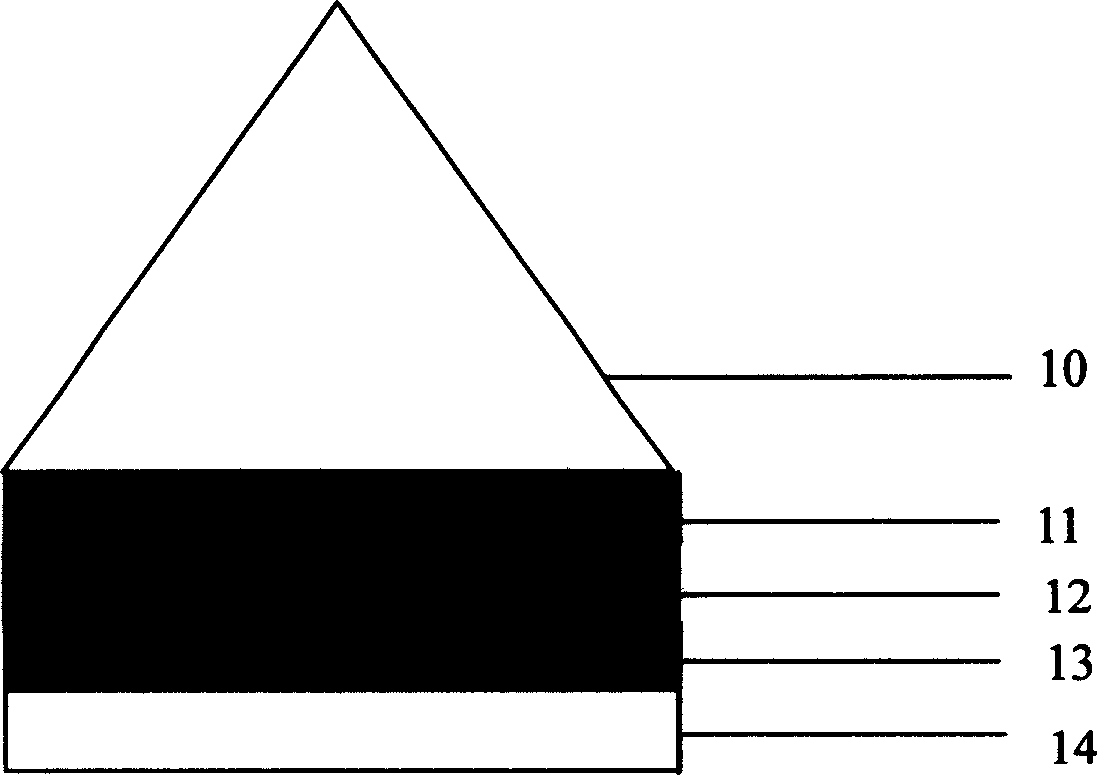

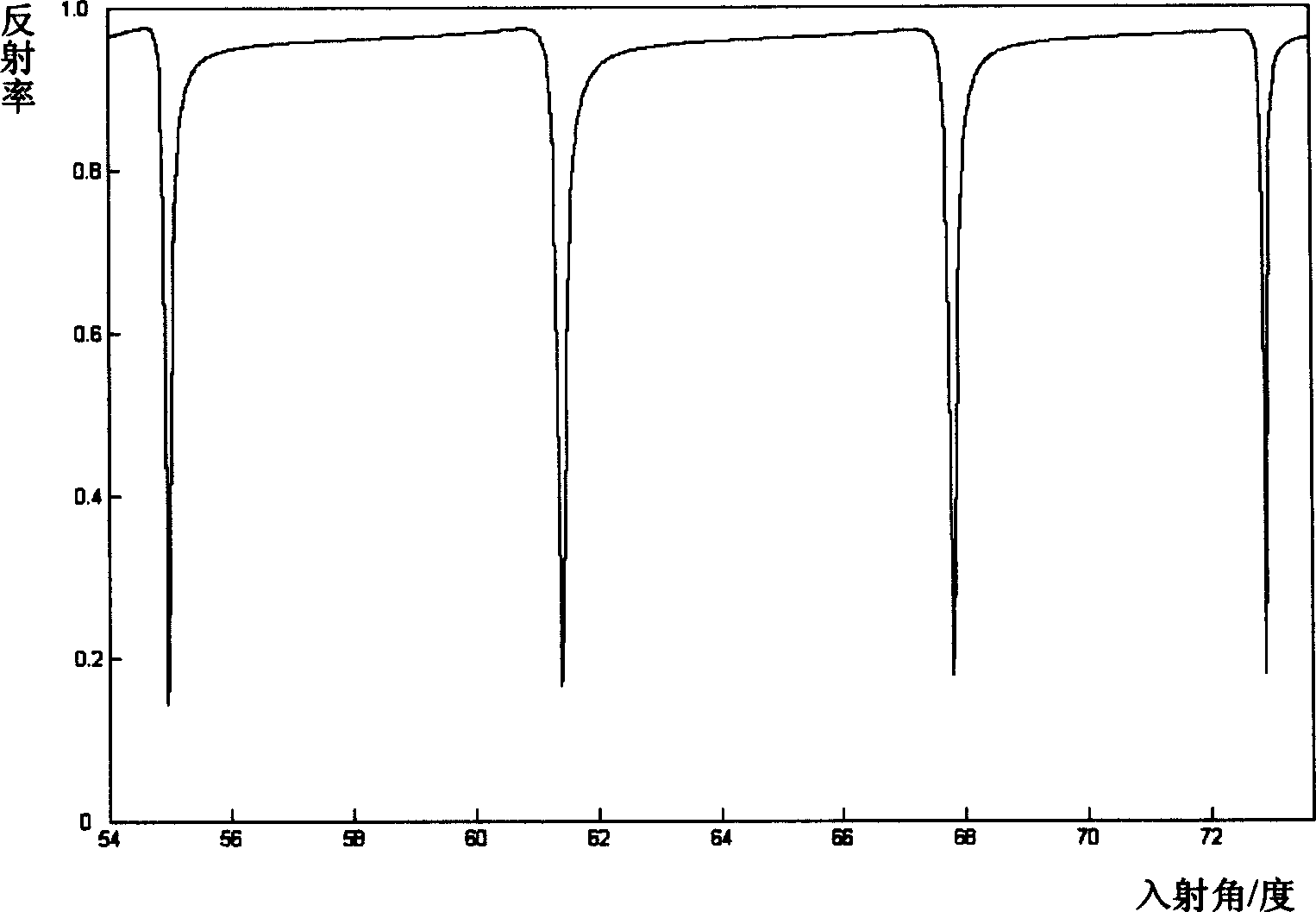

[0031]The incident laser parameters are: center wavelength 800 nm, half width 10 nm. The parameters of the prism / waveguide coupling unit are: the refractive index of the prism 10 is 1.784, the cover layer 11 is a silver film, the thickness is 40 nanometers, the dielectric constant is ε=-20+i, and the waveguide layer 12 adopts a cross-linked organic polymer , with a thickness of 1.7 microns and a refractive index of 1.71. The isolation layer 13 is PMMA with a thickness of 2 microns and a refractive index of 1.5. The substrate layer 14 is a silver film with a thickness of 100 nanometers and a dielectric constant of ε=-20+i.

[0032] Adjust the polarizer 6 so that the polarization direction is horizontal, corresponding to the TM mode, rotate the turntable 2, and observe the light intensity measured by the photodetector at the same time, so that the light intensity reaches the minimum value, observe the reshaped spectrum on the spectrometer, and continue to fine-tune the incident a...

Embodiment 2

[0035] The incident laser parameters are: center wavelength 1310 nm, half width 10 nm. The parameters of the prism / waveguide coupling unit are: the refractive index of the prism 10 is 1.784, the cover layer 11 is a silver film, the thickness is 40 nanometers, the dielectric constant is ε=-54+4i, and the cross-linked organic polymer used in the waveguide layer 12 Thickness is 1.7 micron, and refractive index is 1.71, and isolation layer 13 is PMMA, and thickness is 2 micron, and refractive index is 1.5, and substrate layer 14 is silver film, and thickness is 100 nanometers, and dielectric constant is ε=-54+4i .

[0036] Adjust the polarizer 6 so that the polarization direction is horizontal, corresponding to the TM mode, rotate the turntable 2, and observe the light intensity measured by the photodetector at the same time, so that the light intensity reaches the minimum value, then observe the reshaped spectrum on the spectrometer, and continue to fine-tune the incident angle. ...

Embodiment 3

[0039] The incident laser parameters are: center wavelength 800 nm, half width 10 nm. The parameters of the prism / waveguide coupling unit are: the refractive index of the prism 10 is 1.784, the cover layer 11 is a silver film, the thickness is respectively 40, 50 and 60 nanometers, the dielectric constant is ε=-20+i, and the waveguide layer 12 adopts Cross-linked organic polymer with a thickness of 1.7 microns and a refractive index of 1.71. The isolation layer 13 is PMMA with a thickness of 2 microns and a refractive index of 1.5. The substrate layer 14 is a silver film with a thickness of 100 nanometers and a dielectric constant of ε =-20+i.

[0040] Adjust the polarizer 6 so that the polarization direction is horizontal, corresponding to the TM mode, rotate the turntable 2, and observe the light intensity measured by the photodetector at the same time, so that the light intensity reaches the minimum value, then observe the reshaped spectrum on the spectrometer, and continue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com