Laser quick forming system and forming method with six shaft machine hand for powder material

A laser rapid prototyping, powder material technology, used in laser welding equipment, manufacturing tools, welding equipment, etc., to achieve high forming accuracy, wide application range, and improve the programming environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention will be described in detail below with reference to a specific embodiment.

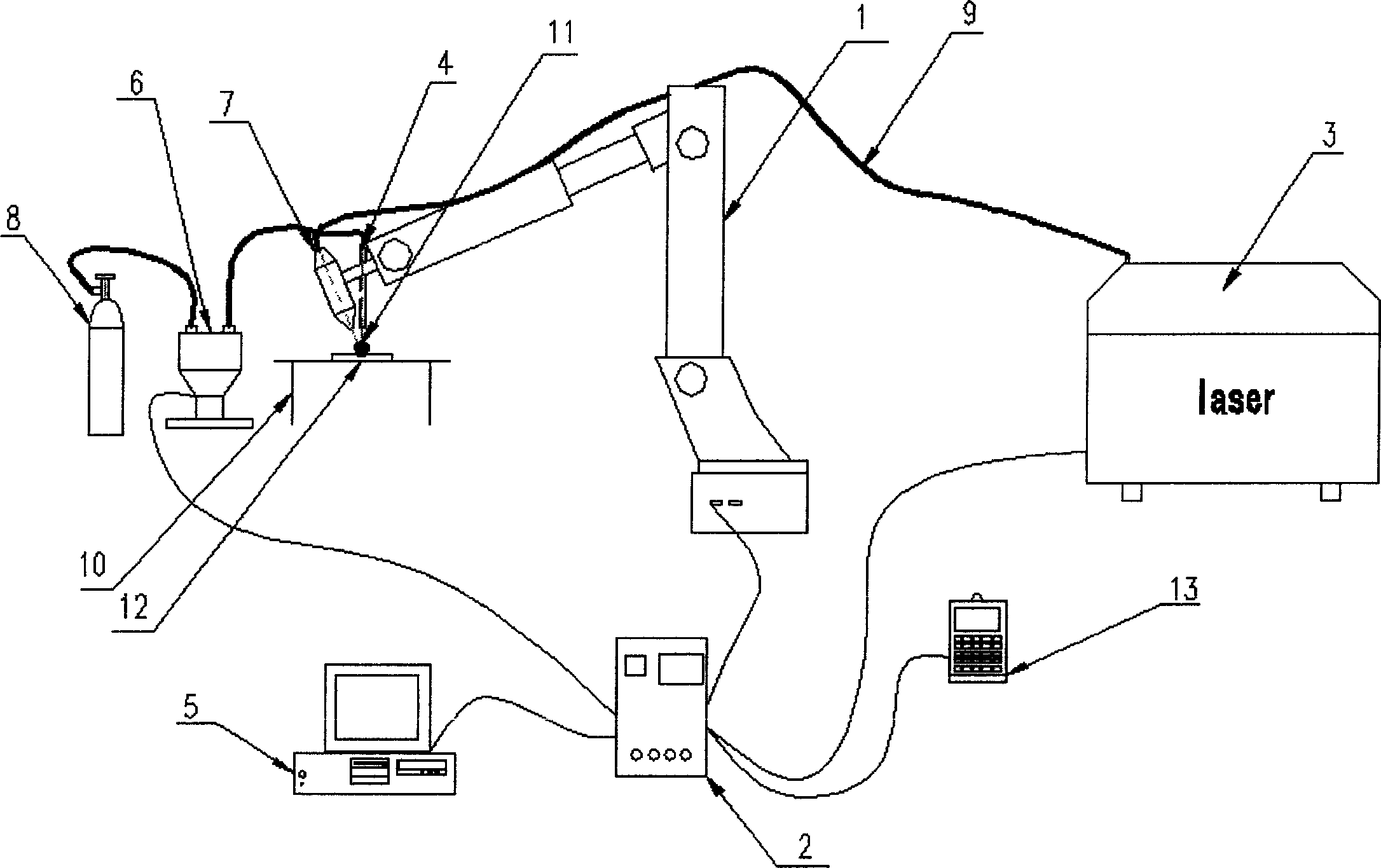

[0041] Refer to the attached figure 1 . Six-axis robot hand 1 adopts Shougang Motoman SK16 robot hand, the positioning accuracy is -0.1mm-+0.1mm, robot hand controller 2 model is XRC; laser 3 adopts HASS company's 1000WNd:YAG laser, the laser can pass through the optical fiber For transmission, the flexibility of the optical fiber itself makes it easy to use with a six-axis robot, so as to meet the needs of flexible processing in free space. The laser light is transmitted to the laser working head 7 through the optical fiber 9 . The laser 3 is connected with the robot controller 2 through the RS-232 standard serial port, so that the system can control the working state of the laser through the robot controller 2. Powder feeder 6 adopts JSF-1 automatic powder feeder. The powder feeder can convey powders of various materials and sizes. When tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com