Purifying and producing process for high purity follicle stimulating hormone in urine

A follicle-stimulating hormone and production process technology, which is applied in the field of follicle-stimulating hormone products through purification, can solve the problems of FSH variability, no biological activity, and unsuitability for industrial production, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Coupling of red dye and Sepharose 4B: Weigh a certain amount of red dye (azo dye, such as Reactive Red 120) ligand and add it to distilled water, so that the initial ligand concentration is 0.5-3.5% (W / V) In between, stir to dissolve, then add 10-50% (W / V) to wash and filter the Sepharose 4B gel, place it in a constant temperature water bath shaker and rise to the required reaction temperature (40-80°C) within 1-10min , then add dyeing aids for dyeing (such as NaCl), and then add NaCl after 30 minutes 2 CO 3 (The final concentration is 10-25g / L) fix for 15min, then add a catalyst (such as DABCO) and react for 2-10 hours. The pH of the reaction was controlled between 9-10. The coupled gel was washed repeatedly with pure water for later use.

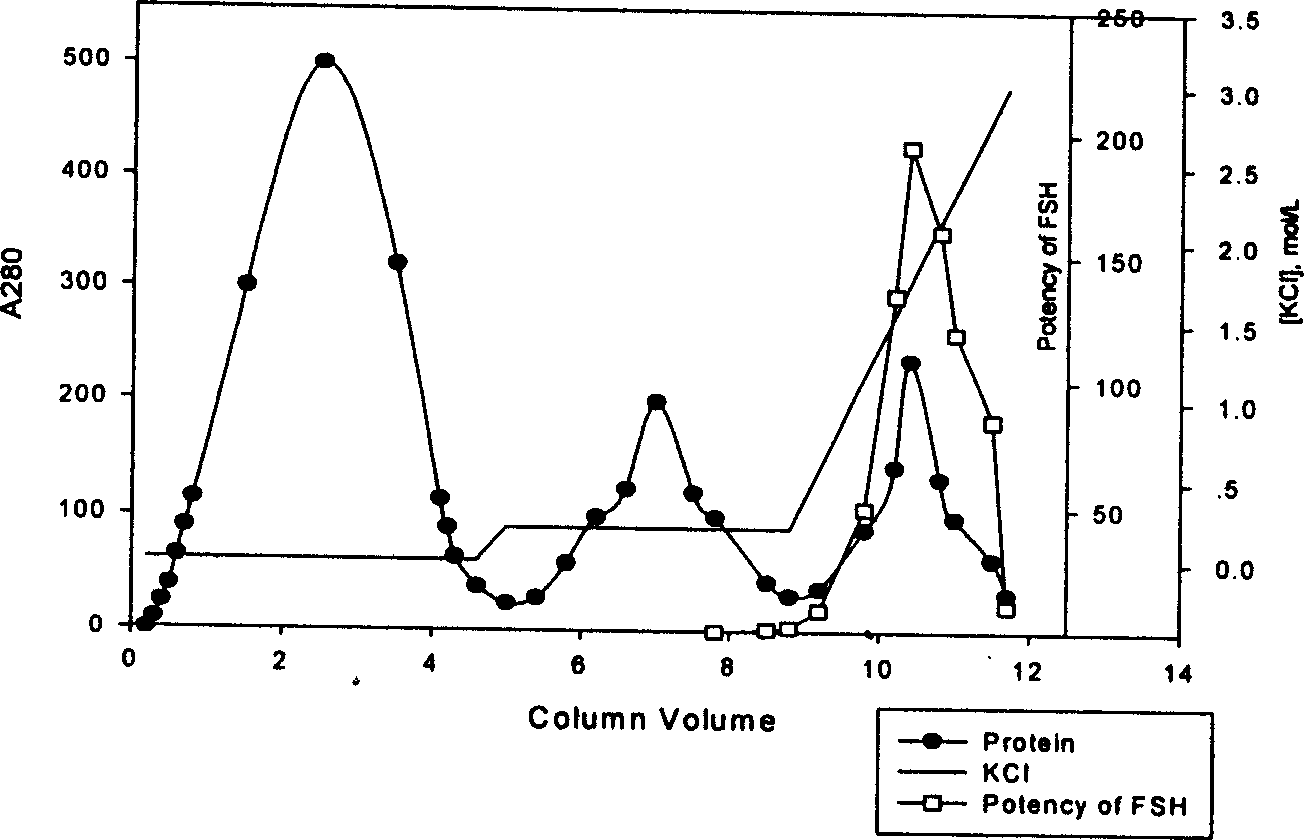

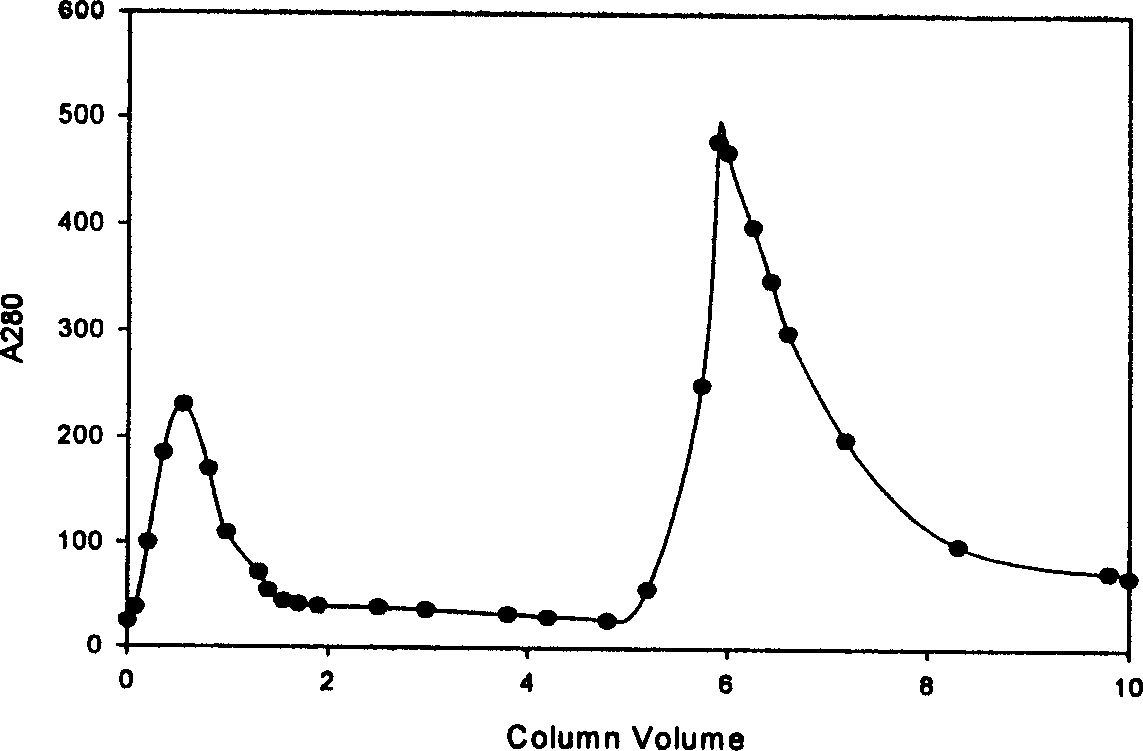

[0012] Purification step 1 of FSH - treatment of crude product: the activity of FSH in crude HMG is about 1 IU / mg, and the activity of LU is about 1 IU / mg. Because the HMG crude product contains a lot of miscellaneous proteins, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com