Heavy oil energy saving agent and its preparing method

An energy-saving agent and heavy oil technology, which is applied in the field of fuel oil additives, can solve problems such as environmental pollution, low combustion efficiency, excessive harmful gas content in exhaust gas, etc., and achieve extensive social benefits, reduce pollution, improve quality and combustion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The heavy oil energy-saving agent of the present invention is composed of raw material vegetable oil, ethanolamine, oleic acid, potassium perchlorate, glycol ether, caustic soda and solvent according to the following parts by weight:

[0021] Vegetable oil 27.5; Ethanolamine 23.5; Oleic acid 3; Potassium perchlorate 1.5; Glycol ether 3; Caustic soda 3; Solvent amount.

[0022] Its preparation method is prepared according to the following process steps:

[0023] The first step, get raw vegetable oil, ethanolamine, caustic soda and appropriate amount of solvent by weight;

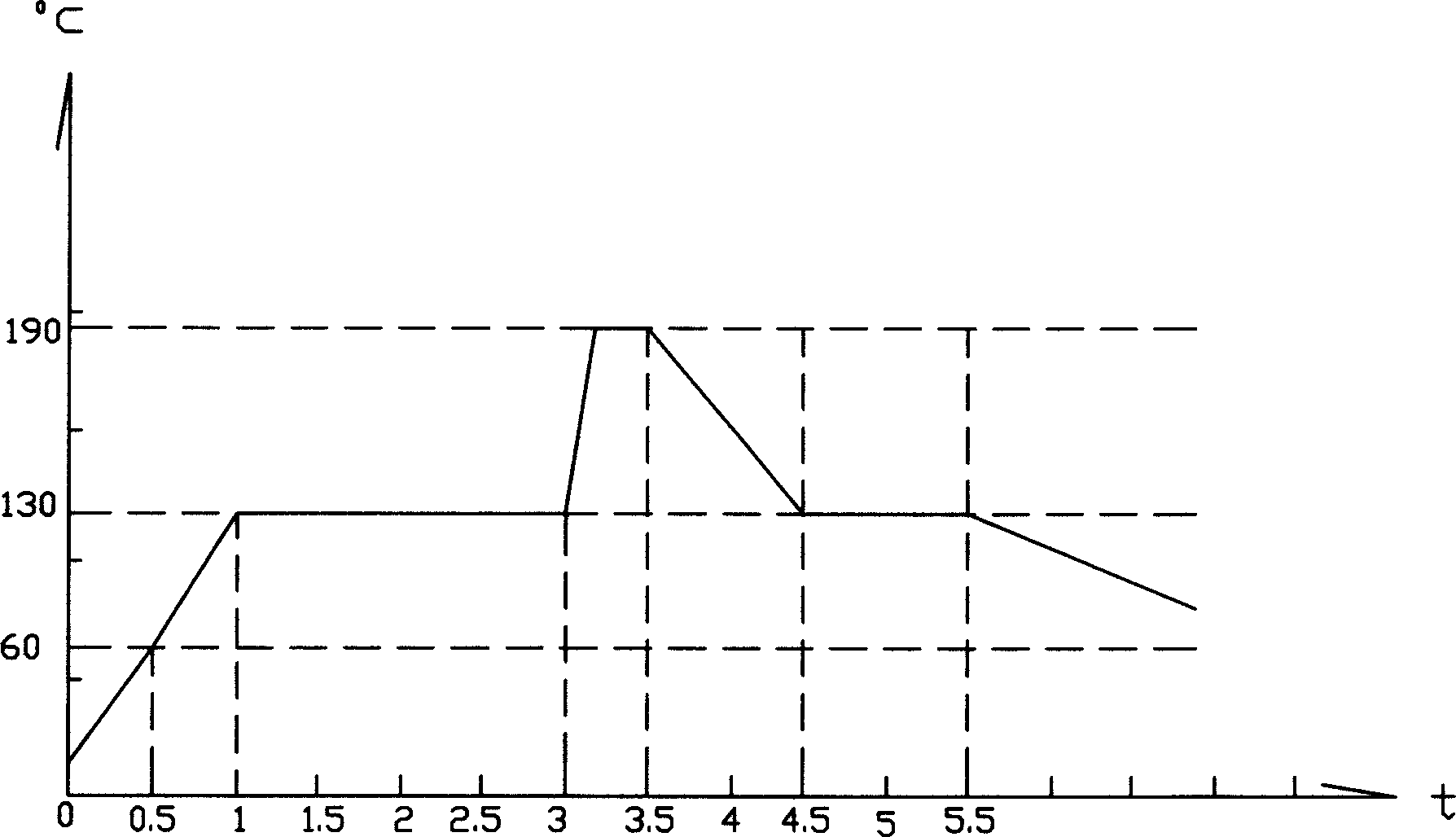

[0024] The second step is to place the raw materials of the first step in the reactor for heating reaction; the first temperature rise is from room temperature to 60±10°C, and the heating time is 0.5 hours; the second temperature rise is from 60±10°C to 130±10°C 10°C, the heating time is 0.5 hours, and then keep warm for 2 hours; the third time the temperature rises from 130±10°C to 190±10°C and then ...

Embodiment 2

[0027] The heavy oil energy-saving agent of the present invention is formed by combining raw material vegetable oil, ethanolamine, oleic acid, potassium perchlorate, glycol ether, caustic soda and solvent according to the following parts by weight: vegetable oil 29; ethanolamine 27.5; oleic acid 5; potassium perchlorate 2; Glycol ether 5; Caustic soda 4; Solvent hydrogen peroxide amount.

[0028] Its preparation method is prepared according to the following process steps:

[0029] The first step, get raw vegetable oil, ethanolamine, caustic soda and appropriate amount of solvent by weight;

[0030] The second step is to place the raw materials of the first step in the reactor for heating reaction; the first temperature rise is from room temperature to 60±10°C, and the heating time is 0.5 hours; the second temperature rise is from 60±10°C to 130±10°C 10°C, the heating time is 0.5 hours, and then keep warm for 2 hours; the third time the temperature rises from 130±10°C to 190±1...

Embodiment 3

[0033] The heavy oil energy-saving agent of the present invention is composed of raw material vegetable oil, ethanolamine, oleic acid, potassium perchlorate, glycol ether, caustic soda and solvent according to the following parts by weight:

[0034] Vegetable oil 30.5; ethanolamine 30.5; oleic acid 7; potassium perchlorate 3.5; glycol ether 7; caustic soda 6; appropriate amount of solvent water.

[0035] Its preparation method is prepared according to the following process steps:

[0036] The first step, get raw vegetable oil, ethanolamine, caustic soda and appropriate amount of solvent by weight;

[0037] The second step is to place the raw materials of the first step in the reactor for heating reaction; the first temperature rise is from room temperature to 60±10°C, and the heating time is 0.5 hours; the second temperature rise is from 60±10°C to 130±10°C 10°C, the heating time is 0.5 hours, and then keep warm for 2 hours; the third time the temperature rises from 130±10°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com