Process for preparing wet type paint coagulating agent and its application

A coagulant and wet technology, applied in the field of environmental pollution control, can solve the problems of unsatisfactory performance and efficiency of chemical additives, and achieve the effect of maintaining long-term safe operation, improving absorption capacity, and excellent adsorption bridging effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

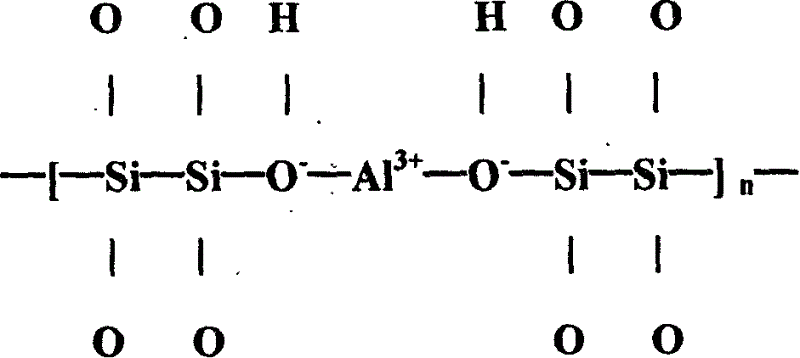

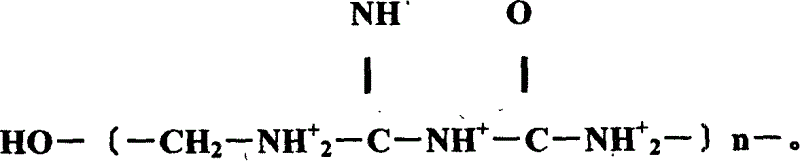

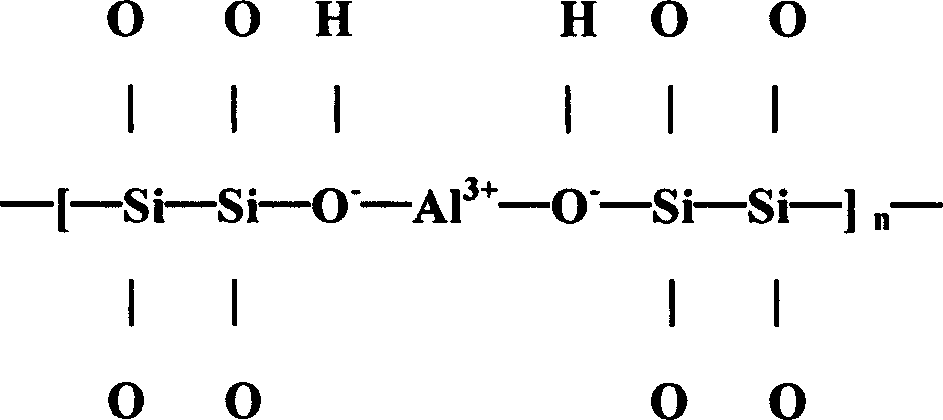

Method used

Image

Examples

Embodiment 1

[0025] Preparation of inorganic polymer substance I: at 20°C, with 42.2 g of Na 2 SiO 3 9H 2 O prepared SiO 2 For an aqueous solution with a weight percent content of 4-5%, add hydrochloric acid at a rate of 20ml / min at a stirring speed of 70rpm to adjust the pH value to 5.0, and after aging for 40min, add AlCl with a weight percent concentration of 23% 3 ·6H 2 78.6 g of O aqueous solution is copolymerized, stirred until it is completely dissolved, and finally a caustic soda solution with a concentration of 20% by weight is added to alkalize the pH value to 4.5-5.5, and it can be matured after 3 hours.

[0026] Preparation of water-soluble low-molecular-weight condensate II: use a water-soluble low-molecular-weight condensate with a molecular weight of 10,000-20,000 (produced by American Surfactant Technologies, trade name Surteck 6253).

[0027] Preparation of paint coagulant: mix 50 grams of the above-mentioned inorganic polymer substance I with 50 grams of water-soluble...

Embodiment 2

[0032] Preparation of inorganic polymer substance I: at 20°C, mix 20g (0.096mol) tetraethoxysilane with 123g water, add 1.0g of hydrochloric acid (31% by weight concentration) at a speed of 20ml / min to obtain SiO 2 The mixture whose weight percentage content is 4.0% adjusts the pH value to 5.0, and after reaction and aging for 1.5 hours, 144g weight percentage concentration of 16% AICl is added 3 .6H 2 The O aqueous solution is alkalized to pH 4.0-5.5 by adding soda ash solution (concentration: 20% by weight), and matured for 3 hours.

[0033] Preparation of water-soluble low-molecular condensate II: using a water-resistant agent (modified melamine-formaldehyde resin, solid content 66%).

[0034] Preparation of paint coagulant: mix 30 grams of the above-mentioned inorganic polymer substance I with 10 grams of water-soluble low-molecular condensate II, and dilute to SiO 2 The weight percent content is 1%, and it is prepared by adding 0.3 gram of glycerol.

[0035] The applic...

Embodiment 3

[0038]Preparation of inorganic macromolecular substance I: at 40 DEG C, 20 grams of water glass with a mole number of 3.1 is dissolved in 60 grams of water, and 50 grams of sulfuric acid with a concentration of 10% by weight is mixed with the above-mentioned solution at a speed of 30ml / min. The stirring speed is 50rpm, adjust the aging pH value to 4.0, after aging for 20min, add 11.4 grams of ZnCl 2 Copolymerize, finally add sodium hydroxide to basify to pH 4.0-5.0, and ripen for 3 hours.

[0039] Preparation of water-soluble low-molecular-weight condensate II: Mix 21 grams of dicyandiamide with 62.1 ml of formaldehyde and 4 grams of ammonium chloride, add 8 ml of 65% sulfuric acid, stir and heat to 50°C, keep for 1 hour, add 4 grams of chloride For ammonium, continue to react for 2 hours and cool to room temperature. The molecular weight is 1,000-100,000.

[0040] Preparation of lacquer coagulant: 9.5 grams of inorganic polymer substance I prepared above and 0.5 gram of wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com