Method of manufacturing bus electrode of plasma display board

A bus electrode and plasma technology, which is applied in the production field of plasma display panel bus electrodes, can solve the problems of complex thin-film photolithography process, low material utilization rate, and long production cycle, and achieve small space occupation and high material utilization rate. The effect of high and huge equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

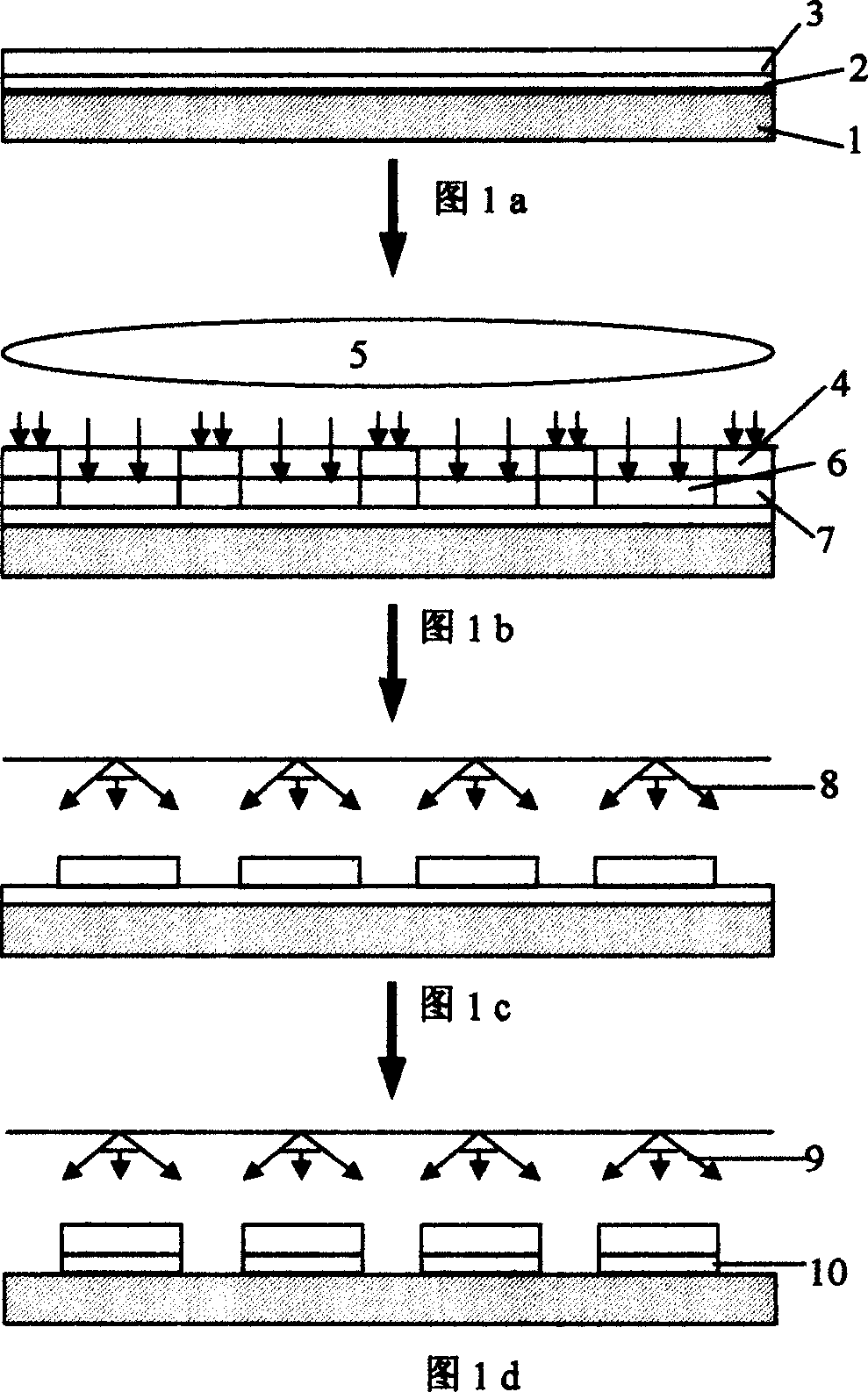

[0025] The substrate is cleaned, and the substrate includes a base glass substrate 1 and a transparent conductive film 2 covered on its surface.

[0026] The photosensitive adhesive 3 is hot-pressed on the surface of the transparent conductive film 2, and the adhesive film should be smooth without air bubbles.

[0027] Exposure: spread the mask plate 4 with line graphics on the surface of the photosensitive adhesive 3 and press it tightly so that the photosensitive adhesive 3 and the mask plate 4 have no gap. Then use ultraviolet light 5 to irradiate mask plate 4 and photosensitive adhesive 3 vertically, ultraviolet light 5 can penetrate the transparent area on mask plate 4 and irradiate the corresponding parts of photosensitive adhesive 3, so that this part of photosensitive adhesive is cured to form a cured The photosensitive glue 6 ; the opaque area on the mask plate 4 can block the irradiation of the ultraviolet light 5 and keep the corresponding parts of the photosensitiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com