Method for eliminating arene from kerosene distillation fraction

A technology of kerosene and distillates, applied in the field of refining aromatics, can solve the problems of high energy consumption and achieve the effect of improving separation efficiency and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

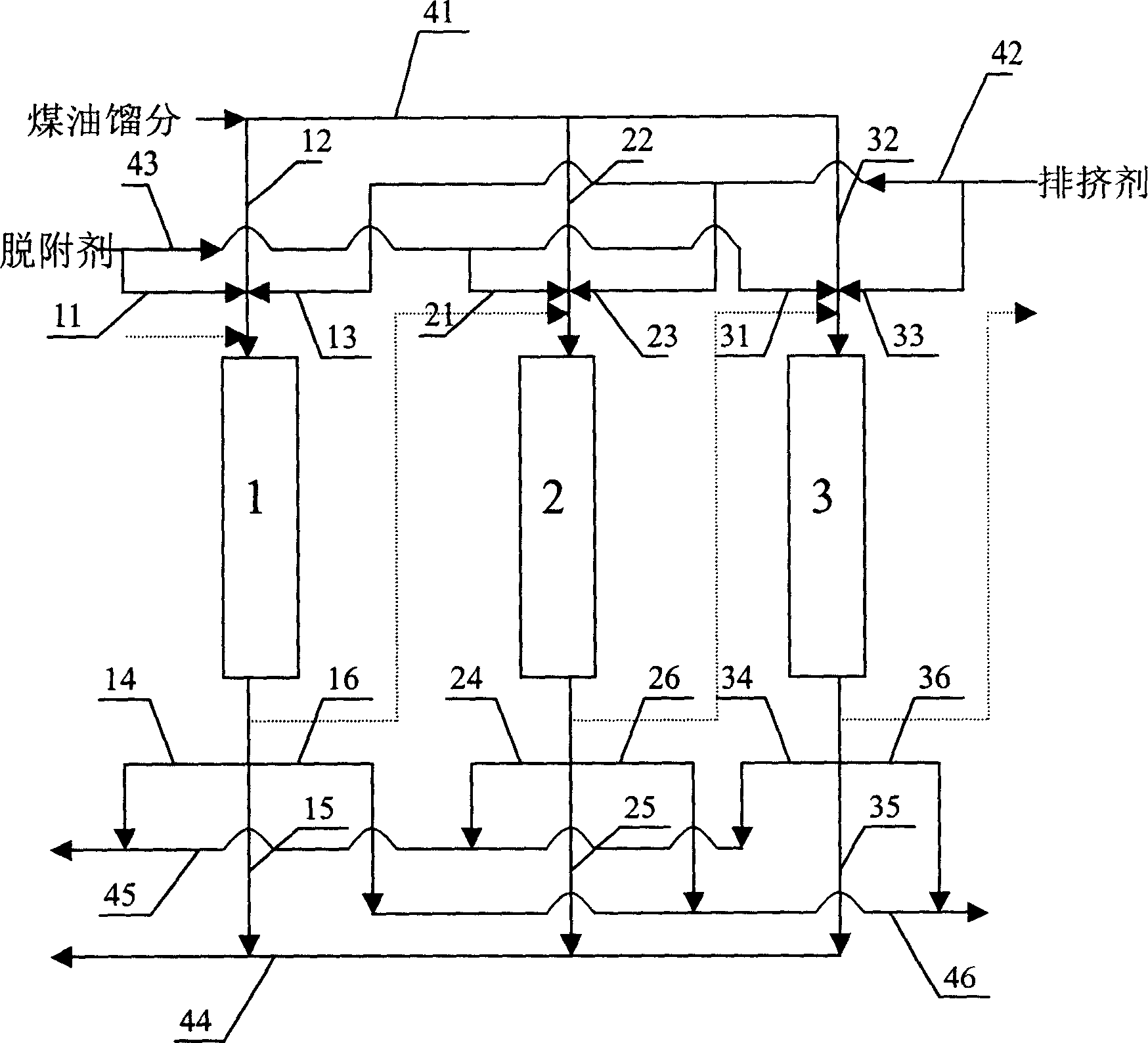

Method used

Image

Examples

example 1

[0025] Prepare the sorbent.

[0026] Get 150 grams of coarse-porous silica gel (produced by Qingdao Ocean Chemical Factory), and activate it in the air at 150°C for 2.5 hours to obtain adsorbent A, wherein the pores of 40-50 Å account for 92% of the total pore volume, and the average particle diameter is 0.1-0.8 mm, wherein particles with a diameter of 0.65-0.8 mm account for 20% by mass, particles with a diameter of 0.2-0.65 mm account for 70% by mass, and particles with a diameter of 0.1-0.2 mm account for 10% by mass, and the surface hydroxyl content is 2.0 mmol / g SiO 2 .

example 2

[0028] After getting 92 grams of NaX zeolite and 8 grams of aluminum hydroxide powder and mixing evenly, roll the ball into shape, and the deionized water sprayed into when rolling the ball is 10 grams in total. Then sieve the ball into small balls with a particle size of 0.2-0.8 mm, and roast at 540°C for 4 hours to obtain Adsorbent B, which contains 92% by mass of NaX zeolite, and the rest is γ-Al 2 o 3 .

example 3

[0030] The following example is an experiment of adsorption separation and dearomatization of kerosene fraction.

[0031]Take 100 grams of adsorbent A and place it in an adsorption column with a diameter of φ20×1200 mm, and feed kerosene raw material for adsorption operation. The operating conditions are: 25°C, kerosene feed volume space velocity 1.0 -1 , The feed oil / agent mass ratio is 0.8. After the adsorption is saturated, feed the displacement agent isopropanol into the adsorption column to replace the kerosene fraction in the dead volume of the adsorption column from the adsorption column. When the volumetric space velocity of the isopropanol feed is 1.0 -1 , the volume ratio of isopropanol feed to adsorbent was 0.3. Then feed the desorbing agent n-hexane to the adsorption column, when the feed volume space velocity of n-hexane is 2.0 -1 , the volume ratio of n-hexane feed to adsorbent was 1.5. The properties and compositions of the kerosene raw material and the sorb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com