Rotary vibration type ore separators

A mineral concentrator and tower-type technology, applied in the field of multi-layer disc rotary vibrating tower-type mineral concentrator, can solve problems such as unstable center of gravity, and achieve the effect of reasonable layout, large processing capacity, and clear overall structure scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

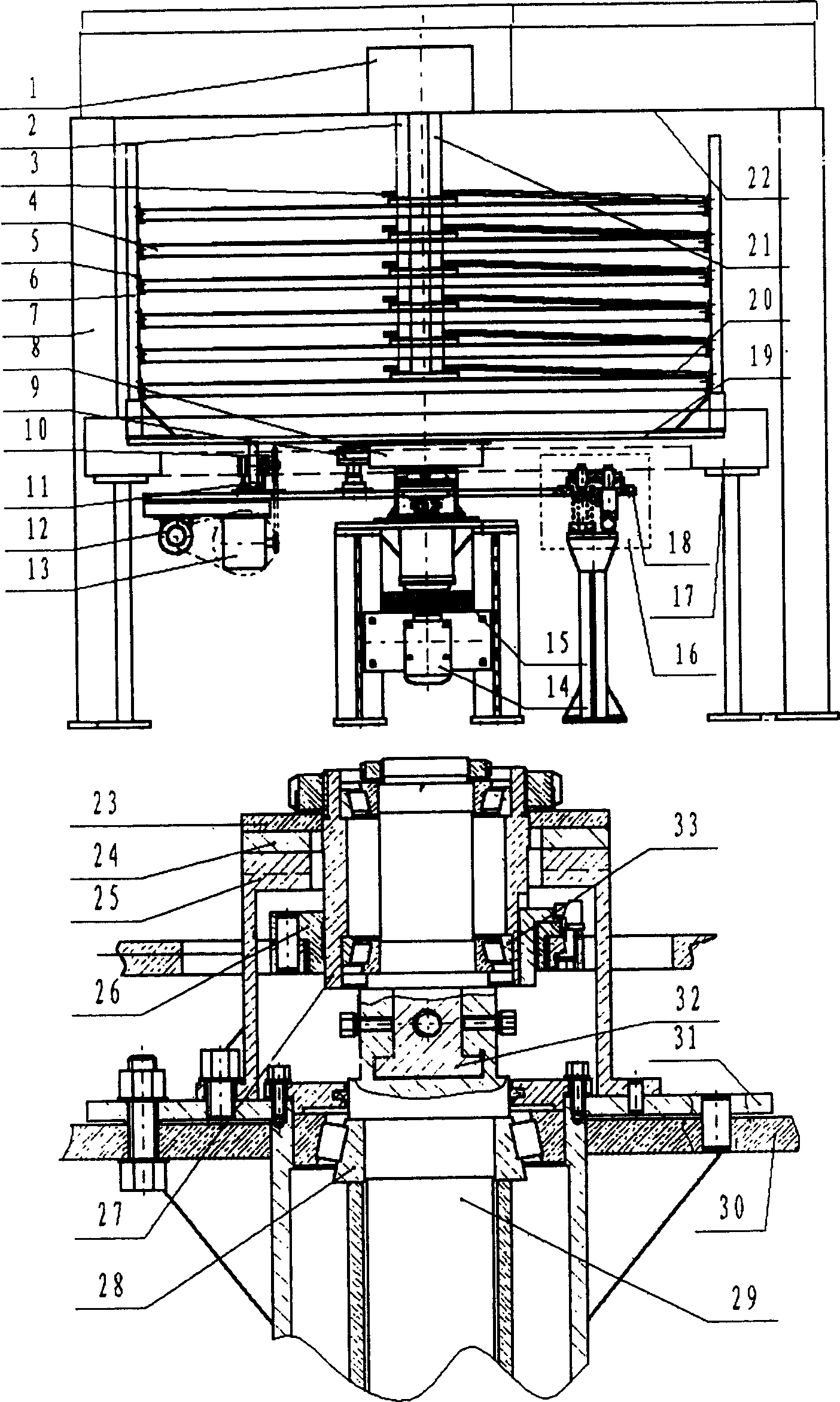

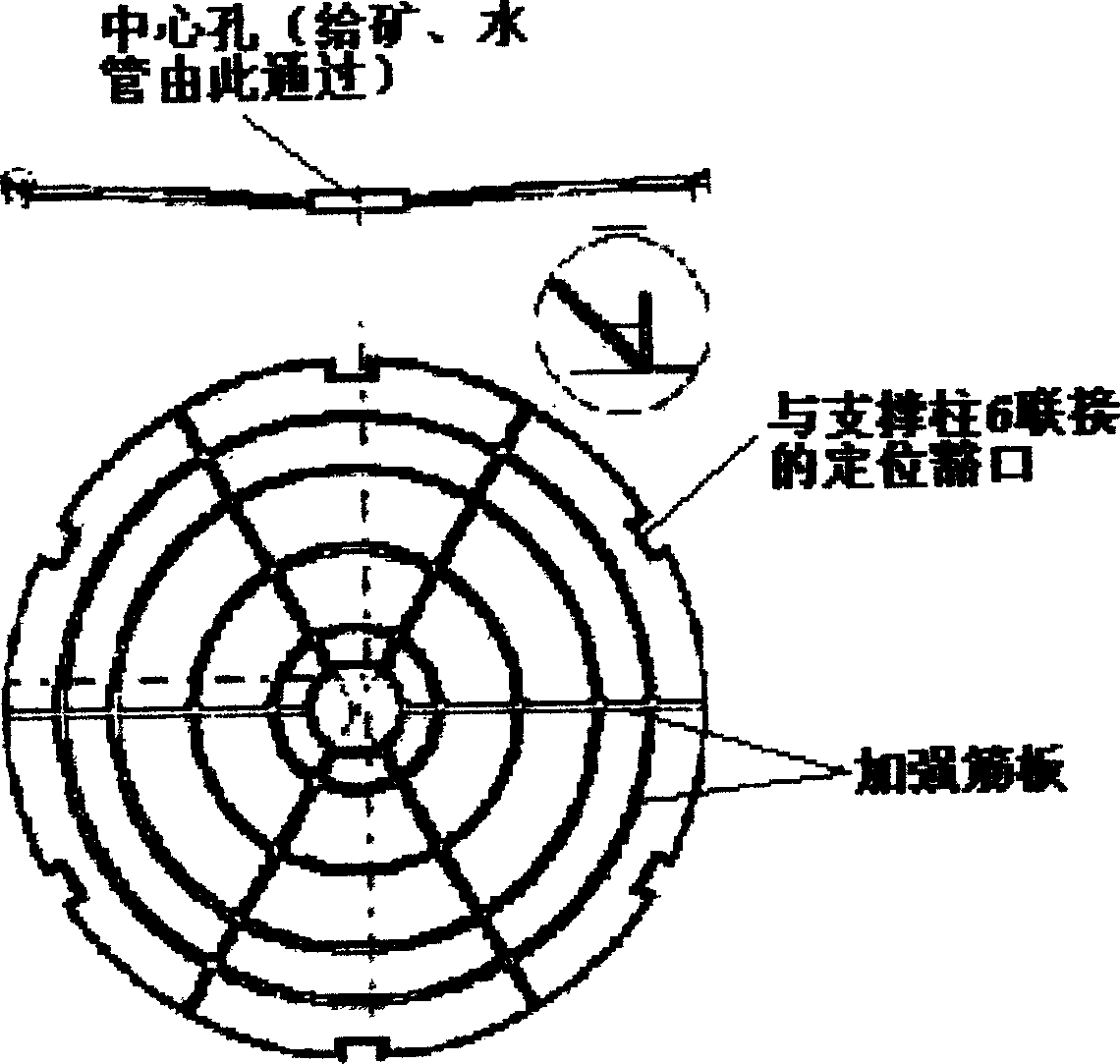

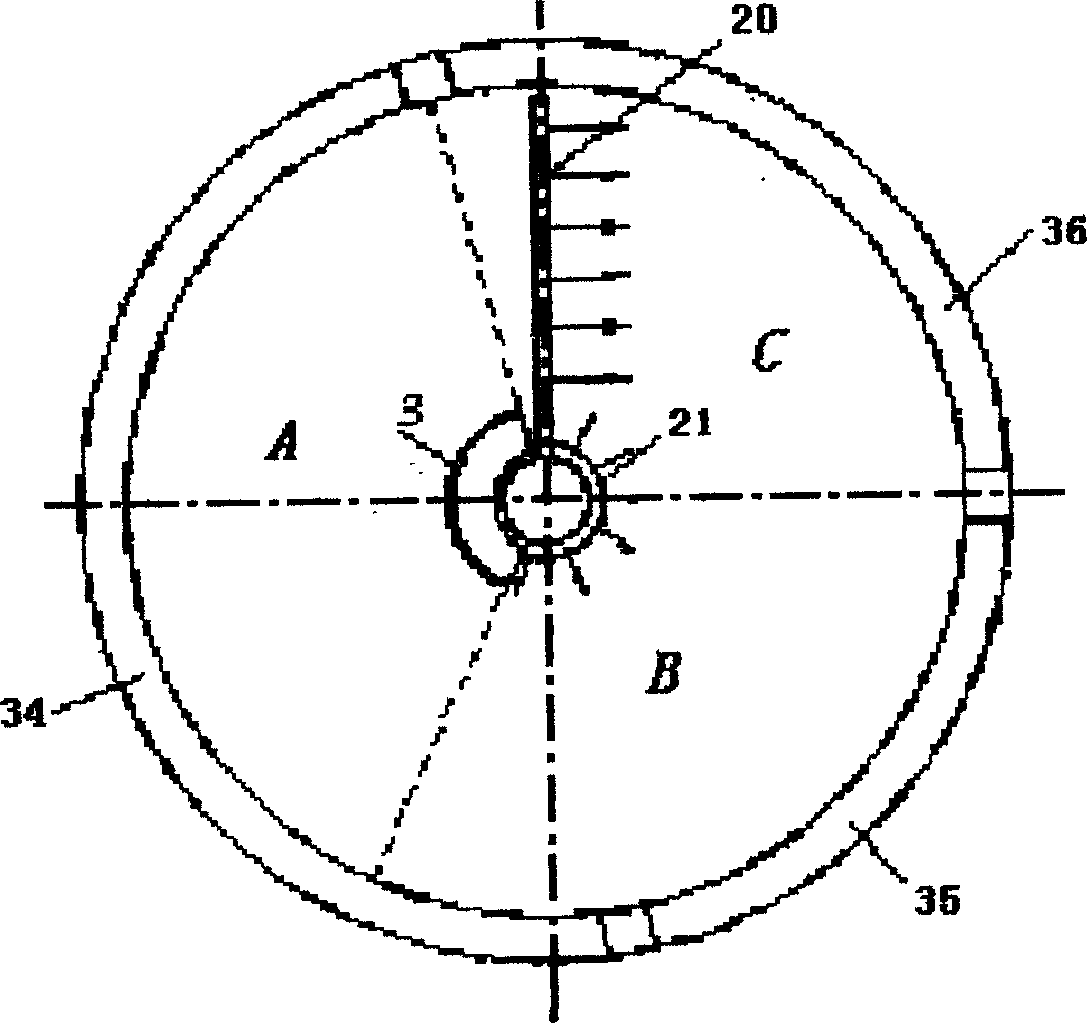

[0034] figure 1 It is a schematic diagram of the whole machine structure of the present invention, and the components in the figure are: ore separating device 1; ore feeding pipe 2; ore feeding device 3; separating disk surface 4; separating disk support 5; supporting column 6; frame 7; Vibration transmission plate 8; friction roller 9; sprocket 10; friction wheel 11; motor 12; worm gear reducer 13; motor 14; pulley 15; ; Flushing water pipe 20; Washing water pipe 21; Working platform 22; Upper slider 23; Middle slider 24; Slider bracket 25; Seat 31; Driven shaft 32; Bearing 33.

[0035] Wherein, the sorting disc 4 has 6 layers, all of which are made of glass fiber reinforced plastics, and are high in the middle and low in the periphery of the conical disc surface. The sorting disc surface 4 is fixed on the sorting disc support 5 of the support post 6 in parallel and evenly with bolts, and the support post 6 is fixed on the upper pallet 19. The friction wheel 11 is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com