Laser impact treating method and apparatus with ice as constraint layer

A technology of laser shock and confinement layer, which is applied in laser welding equipment, manufacturing tools, welding equipment and other directions to achieve the effect of good confinement, low cost and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

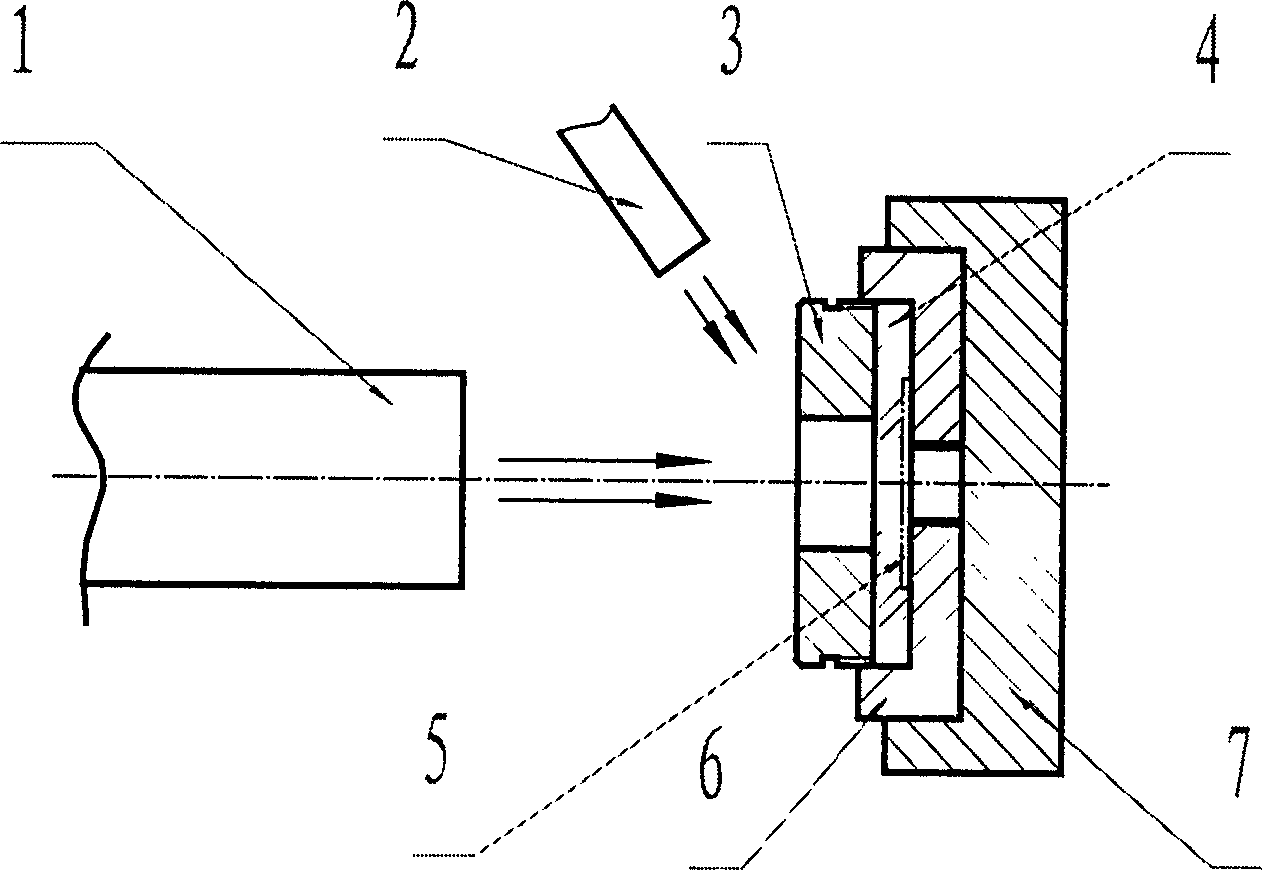

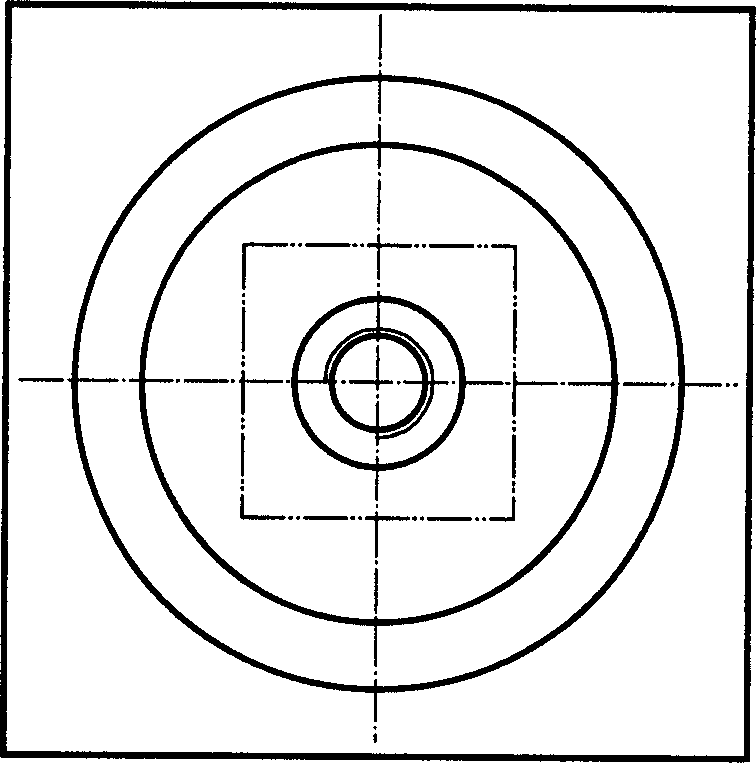

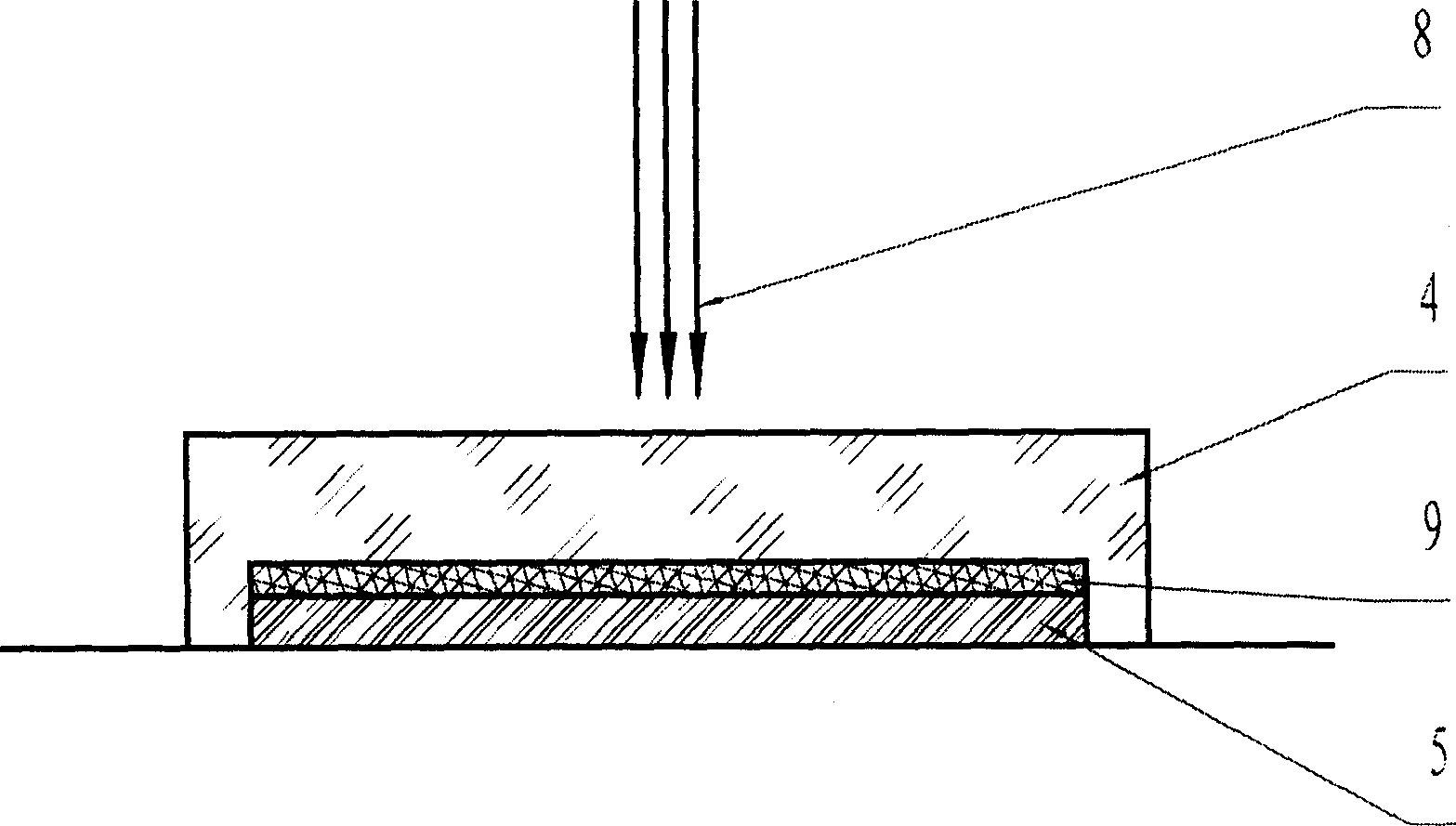

[0025] Such as figure 1 As shown, the positioning reference seat 7 is placed in the laser optical path system 1, and the optical path is adjusted. Put the impacted workpiece 5 coated with the energy absorbing layer 9 inside the fixture base 6, rotate the screw briquetting block 3 to the required position, and be used to control the height of the ice layer. Below the bottom of the screw press block 3. Put the water-injected fixture base 6 into the positioning reference seat 7, unscrew the screw press block 3, and then use the refrigeration system 2 to blow high-pressure nitrogen into the impacted workpiece 5, and quickly form an ice-constrained layer of required thickness on the surface of the workpiece 4. Generally, the thickness of the ice confinement layer 4 is controlled within 10mm, and the temperature of the ice is controlled at about -7°C. The jig base 6, the impacted workpiece 5 and the ice confinement layer 4 are integrated when ice is prepared. Screw on the screw b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com