Fibre reinforced plastic and concrete composite arc structure and construction method

A fiber-reinforced plastic and concrete arch technology, which is applied in the field of building components and construction, can solve the problems of weakening the overall rigidity of the structure, aggravating the corrosion of steel bars, and reducing the durability of the structure, so as to prevent moisture from entering the interior of the concrete, excellent corrosion resistance, and excellent Closed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

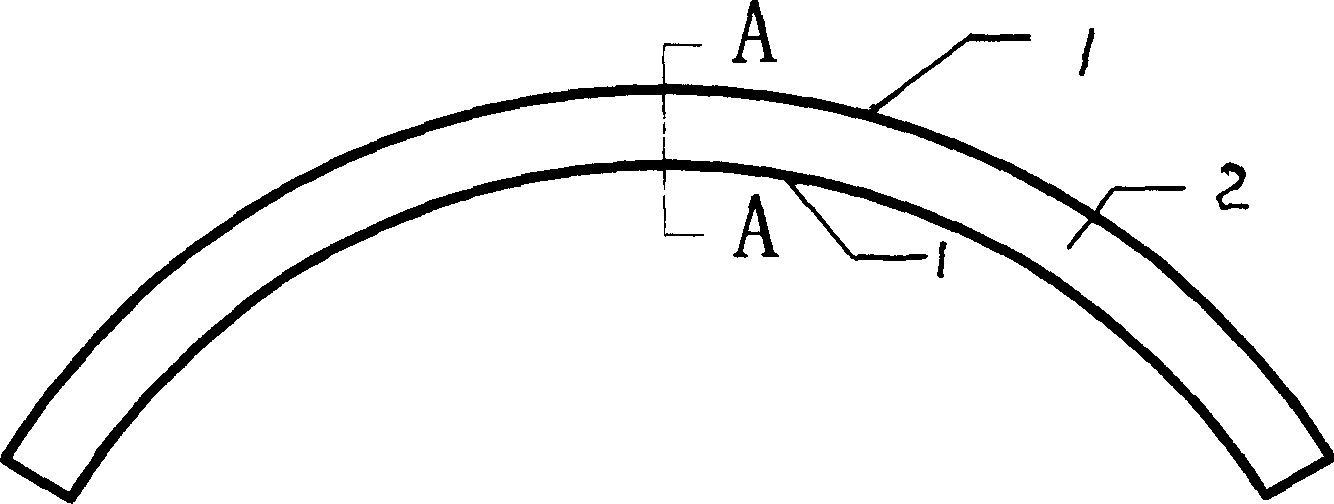

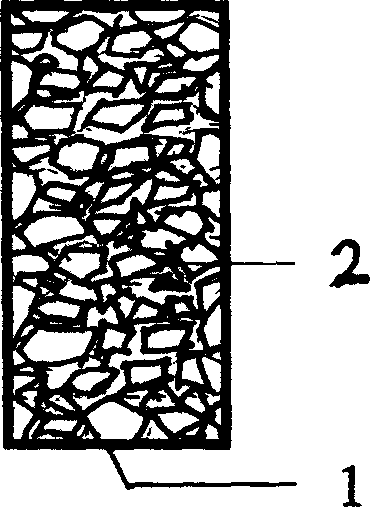

[0041] Such as figure 1 , figure 2 As shown, the outer wall of the concrete arch 2 is pasted with a fiber-reinforced plastic layer 1 .

[0042] Example of construction method: the concrete arch 2 is formed by bracket construction. When the strength of the concrete reaches 86% of the design strength, the surface laitance of the concrete arch 2 is wiped off with an electric grinding wheel to form a certain roughness, and the corners of the section are rounded. Smooth the holes on the concrete surface with epoxy putty, and brush the underlying structural adhesive on the concrete surface. The underlying structural adhesive is made of epoxy resin and epoxy curing agent at a weight ratio of 100:32, and the thickness of the underlying structural adhesive is 0.4mm After 50 minutes of brushing the underlying structural adhesive, wrap the glass fiber layered cloth on the surface of the underlying structural adhesive smoothly, and then manually brush the resin on the glass fiber layere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com