Ginger extract preparation

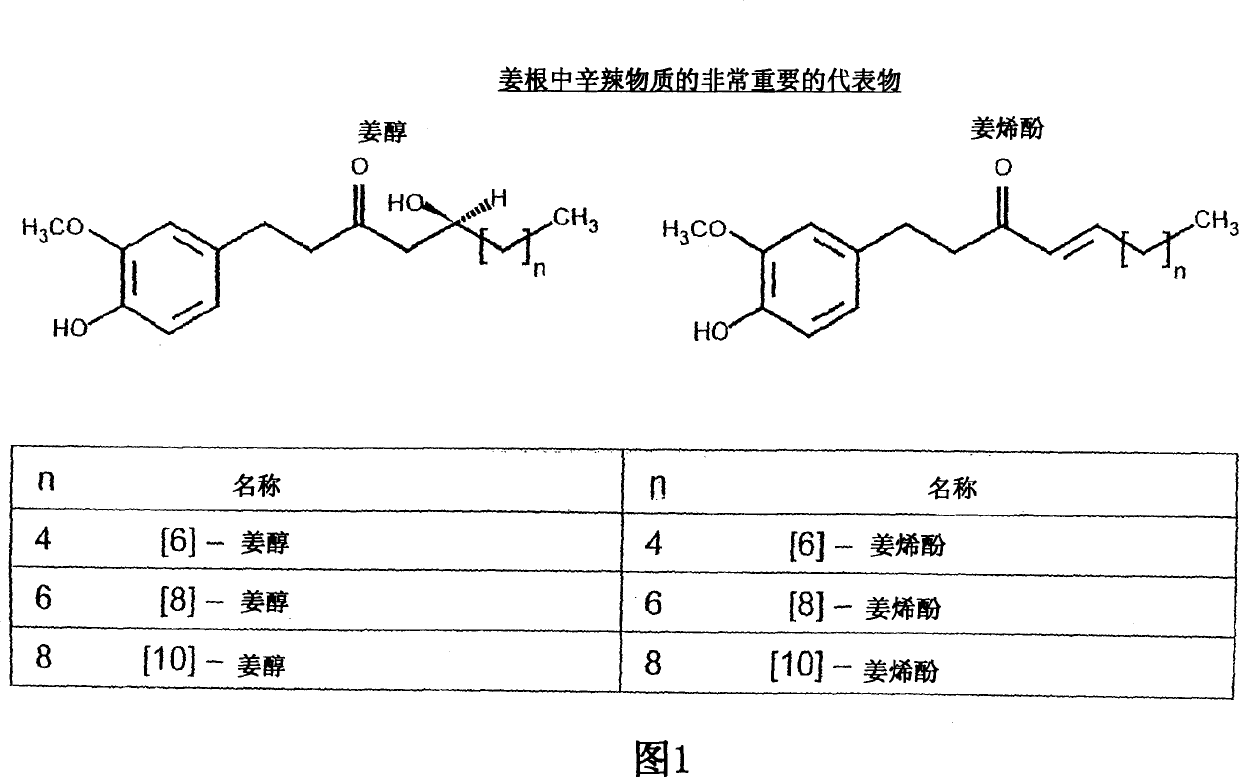

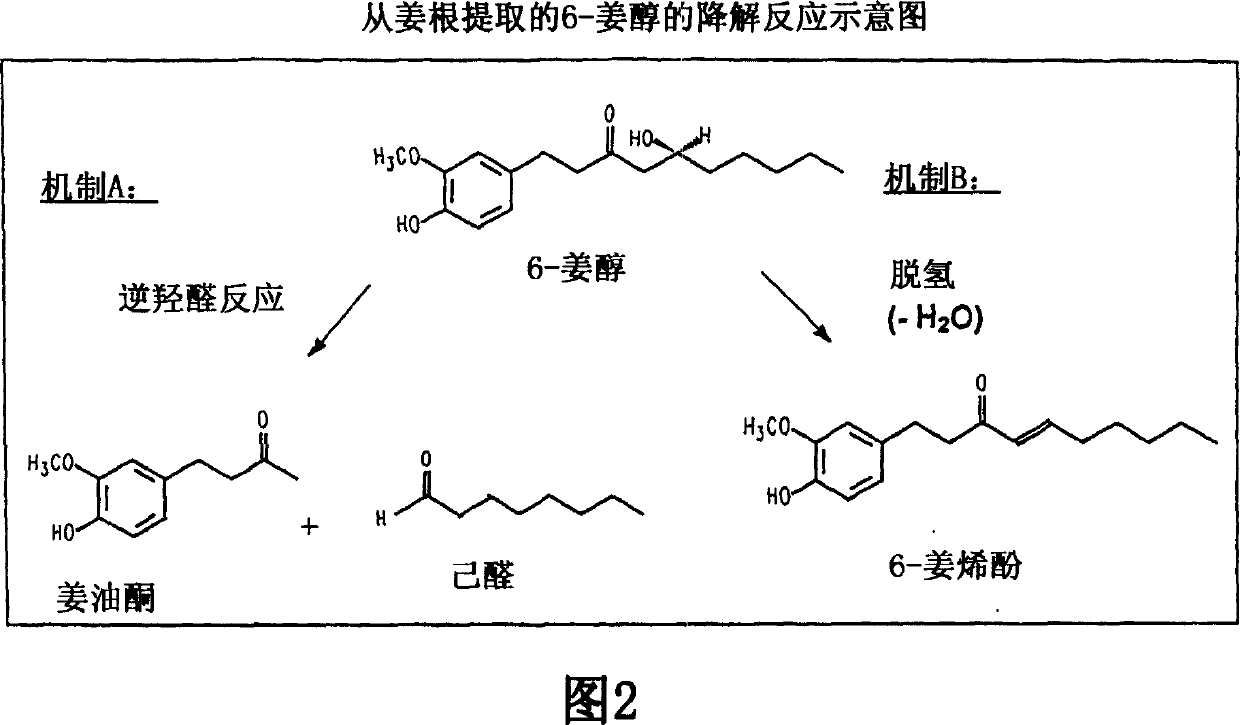

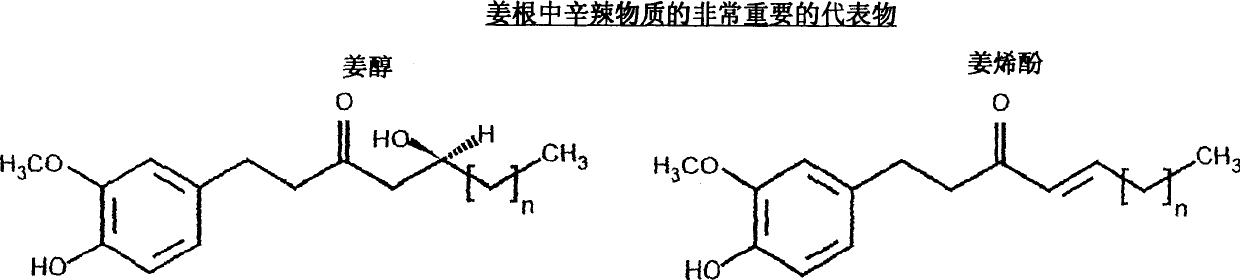

A ginger extract and preparation technology, which is applied in the production field of ginger extract preparations, can solve the problems of loss of gingerol stability and inability to prevent dehydration, and achieve the effect of increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Comparative Example 1-Sample A: Unstabilized concentrated extract of ginger (extract Zingiberise rhiz.spir.spiss.)

[0043] 50 kilograms of ginger rhizomes, chopped and sieved into small pieces of 6-8mm, use 500 kilograms of ethanol 96% [V / V] to infiltrate thoroughly. The production temperature does not exceed 45°C. The filtrate, ethanol mobile phase were combined and gently concentrated in vacuo at 45°C to form a paste extract.

Embodiment 2

[0044] Example 2-Sample B: Preparation of ginger, stabilized with Colidan 25

[0045] 45.5 grams of the starting extract-similar to the preparation of sample A (extract Zingiberis e rhiz.spir.spiss.), with a dry solids content of 33%-equivalent to 15 grams of dry extract-it uses more than 99% ethanol Dilute to 20% dry solids. Stir vigorously for 15 minutes- Solution 1 .

[0046] 99.75 grams of Coledan 25 are diluted with more than 99% ethanol with stirring to 10% dry solids. Stir vigorously for 30 minutes- Solution 2 .

[0047] The two solutions were mixed in proportions under stirring at room temperature, resulting in a clear red-brown solution. Stirring was carried out for 30 minutes, and the mixture was gently concentrated in a rotary evaporator at a maximum temperature of 45°C in a water bath. The obtained extract preparation was evaporated to no solvent, and dried in a drying oven at 45°C under vacuum. Add 5% silica as an auxiliary.

[0048] Sample

Analysis p...

Embodiment 3

[0070] The concentrated ginger extract produced similarly to Comparative Example 1 contains 15.8% of the total pungent substances and 15.1% of essential oils (natural DER 12:1). For this, 10.0 kg of spissum extract is absorbed by 10.0 kg of diatomaceous earth and the production volume is 10 kg / kg mixture using carbon dioxide extraction. The anhydrous yield of oily ginger extract accounts for 34% of the extract used. The obtained ginger oleosomes contained 22.7% of the total pungent substances and 39.0% of essential oils (DER natural 35:1).

[0071] 15 grams of ginger oleosomes are diluted with >99% ethanol to contain 20% dry solids. Stir for 30 minutes until a homogeneous solution is obtained- Solution 1 . 85 grams of Collidan 25 was diluted with >99% ethanol and stirred until it contained 10% dry solids. Stir vigorously for 30 minutes- Solution 2 .

[0072] The two solution parts were stirred at room temperature and mixed in proportion to obtain a red-brown, clear solution. Stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com