Compound antiseptic agent

A technology of compounding antibacterial agents and zinc oxide, applied in the field of antibacterial agents, can solve the problems of unsatisfactory antibacterial effect, complex processing technology, small adaptability range, etc., and achieve stable antibacterial and bacteriostatic effect, simple processing technology, advanced and reasonable effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

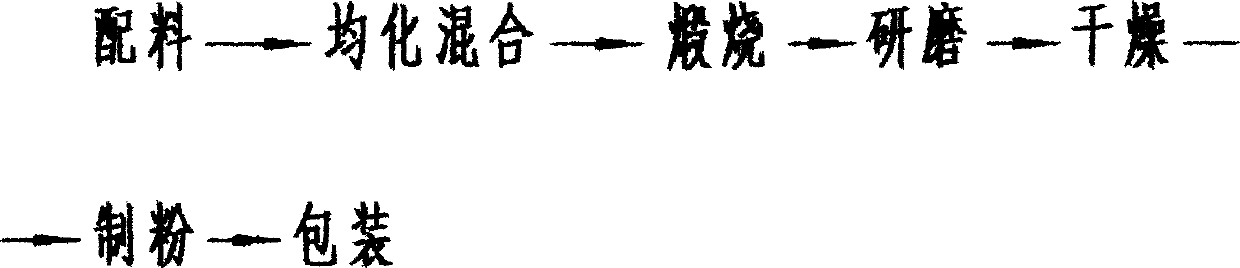

Examples

specific Embodiment

[0009] Below is the specific embodiment of the present invention 1000g: (table one)

[0010] Group

[0011] Mix the components in Table 1 with silver carbonate, zinc oxide and silicon dioxide according to the weight percentage, then put the prepared materials into the ball mill for homogenization and mixing, and send the homogenized and mixed materials into The high-temperature frit is calcined in an electric furnace. The calcining temperature is controlled at 1100°C and the time is controlled at 12 hours. The batch dryer is dried to keep the moisture content below 3%, and the dried material is sent to the sieve-type flour mill to make powder, the particle size is controlled at 5um-45um, and the prepared powdery material is avoided. Just pack it. The oxide content of the finished product is: silver oxide 42%-46%, zinc oxide 36%-44%, silicon dioxide 8%-10%. To meet the needs of different industries, the present invention can be widely used in many industries such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com