Preparation method of Ca3Co2O6 based oxide thermoelectric material

A technology of thermoelectric materials and oxides, applied in chemical instruments and methods, cobalt compounds, calcium/strontium/barium compounds, etc., can solve the problems of high reaction temperature, long reaction time, difficult grain size, etc., and achieve chemical stability. High, short reaction time, fast sintering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

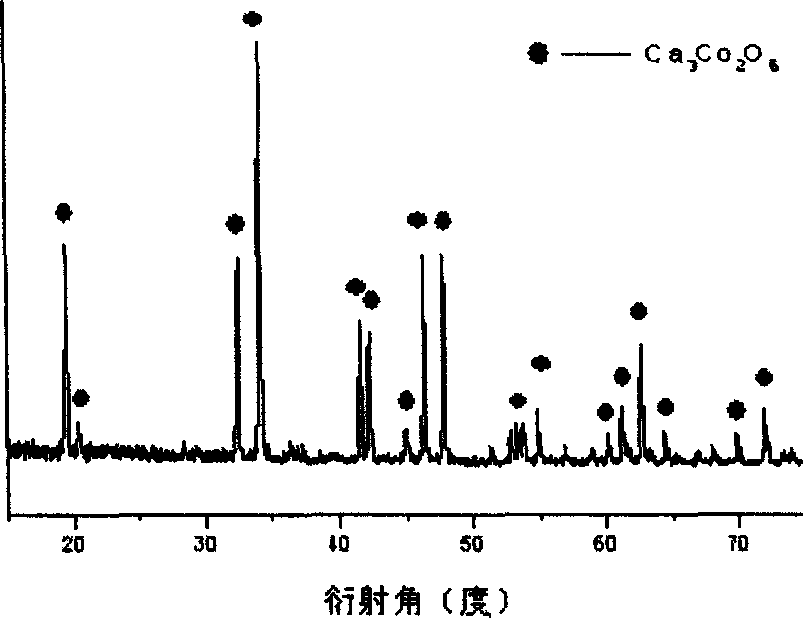

[0047] [Example 1] Ca 3 co 2 o 6 Compound preparation

[0048] Accurately weigh 1.18 grams of Ca(NO 3 ) 2 4H 2 O, 0.97 g Co(NO3)2 6H 2 O, 0.5 mL CH 3 CH 2 OH and 1.75 g C 6 h 8 o 7 ·H 2 O, placed in a reaction vessel, add 49.5 milliliters of deionized water therein, after the above-mentioned raw materials are fully dissolved, slowly add ammoniacal liquor prepared dropwise under constant stirring (water: strong ammoniacal liquor volume ratio is 1: 2), when the solution When the pH value reaches 1.2, stop adding ammonia water dropwise, and continue stirring for 1 hour to obtain a light purple-red clear colloid. The obtained colloid is further stirred and concentrated to obtain xerogel. Grind the xerogel into powder, put it into a muffle furnace for pretreatment at 400°C for 2 hours, then heat it to 950°C and keep it warm for 2 hours to obtain the desired Ca 3 co 2 o 6 powder. Finally, the powder product is ground, put into a mold, placed in a spark plasma sinter...

Embodiment 2

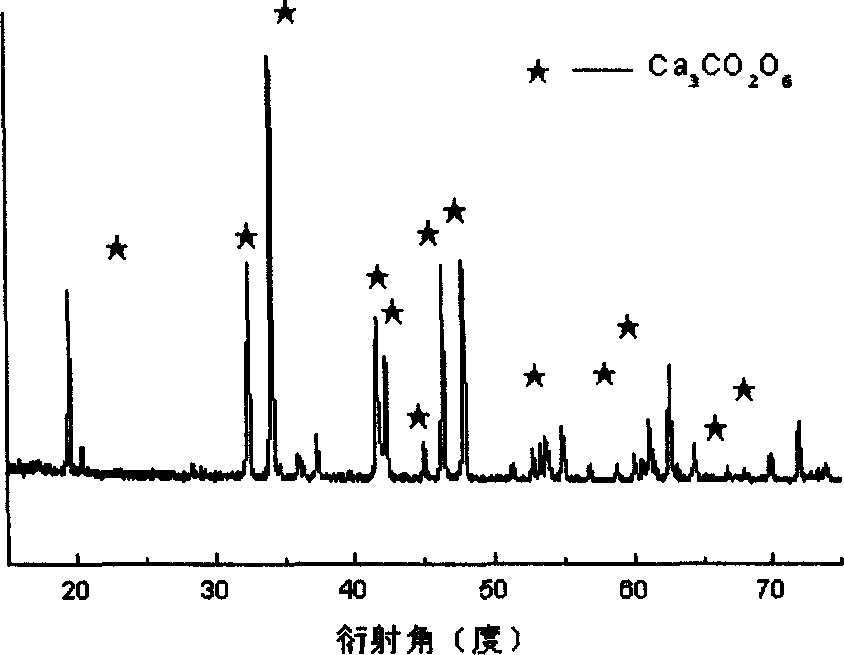

[0049] [Example 2] Ca 3 co 2 o 6 Compound preparation

[0050] Accurately weigh 1.18 grams of Ca(NO 3 ) 2 4H 2 O, 0.97 g Co(NO 3 ) 2 ·6H 2 O, 0.5 mL CH 3 CH 2 OH and 3.5 g C 6 h 8 o 7 ·H 2 0, be placed in a beaker, add 49.0 milliliters of deionized water therein, after the above-mentioned raw materials are fully dissolved, slowly add ammoniacal liquor prepared dropwise under constant stirring (water: concentrated ammoniacal liquor volume ratio is 1: 2), when the solution ph When the value reaches 2.7, stop dripping ammoniacal liquor, continue to stir to obtain dark red transparent colloid. Concentrate the obtained colloid to obtain xerogel. Grind the xerogel into powder, put it into a muffle furnace for pretreatment at 500°C for 2 hours, then heat it to 900°C and keep it for 4 hours to obtain the desired Ca 3 co 2 o 6 powder. Finally, the powder product is ground, put into a mold, placed in a spark plasma sintering (SPS) furnace, heated to 900°C at a heating...

Embodiment 3

[0051] [Example 3] Ca 3 co 2 o 6 Compound preparation

[0052] Accurately weigh 1.18 grams of Ca(NO 3 ) 2 4H 2 O, 0.97 g Co(NO 3 ) 2 ·6H 2 O, 1.0 ml C 64H124O26 and 0.875 g C 6 h 8 o 7 ·H 2 0, be placed in a beaker, add 49.0 milliliters of deionized water therein, after the above-mentioned raw materials are fully dissolved, slowly add ammoniacal liquor prepared dropwise under constant stirring (water: concentrated ammoniacal liquor volume ratio is 1: 2), when the solution ph When the value reaches 3.5, stop dripping ammoniacal liquor, continue to stir to obtain light red clear colloid. Concentrate the obtained colloid to obtain xerogel. Grind the xerogel into powder, put it into a muffle furnace for pretreatment at 600°C for 2 hours, then heat it to 900°C and keep it for 8 hours to obtain the desired Ca 3 co 2 o 6 powder. Finally, the powder product is ground, put into a mold, placed in a spark plasma sintering (SPS) furnace, heated to 950°C at a heating rate o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com