Catalytic oxidation-bioreactor waste gas treatment apparatus

A technology for waste gas treatment equipment and bioreactors, which is applied in chemical instruments and methods, air quality improvement, separation methods, etc., can solve the problems of high investment, prolonged residence time, and high operating costs, and achieves simple operation and maintenance. Auxiliary equipment, the effect of improving purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

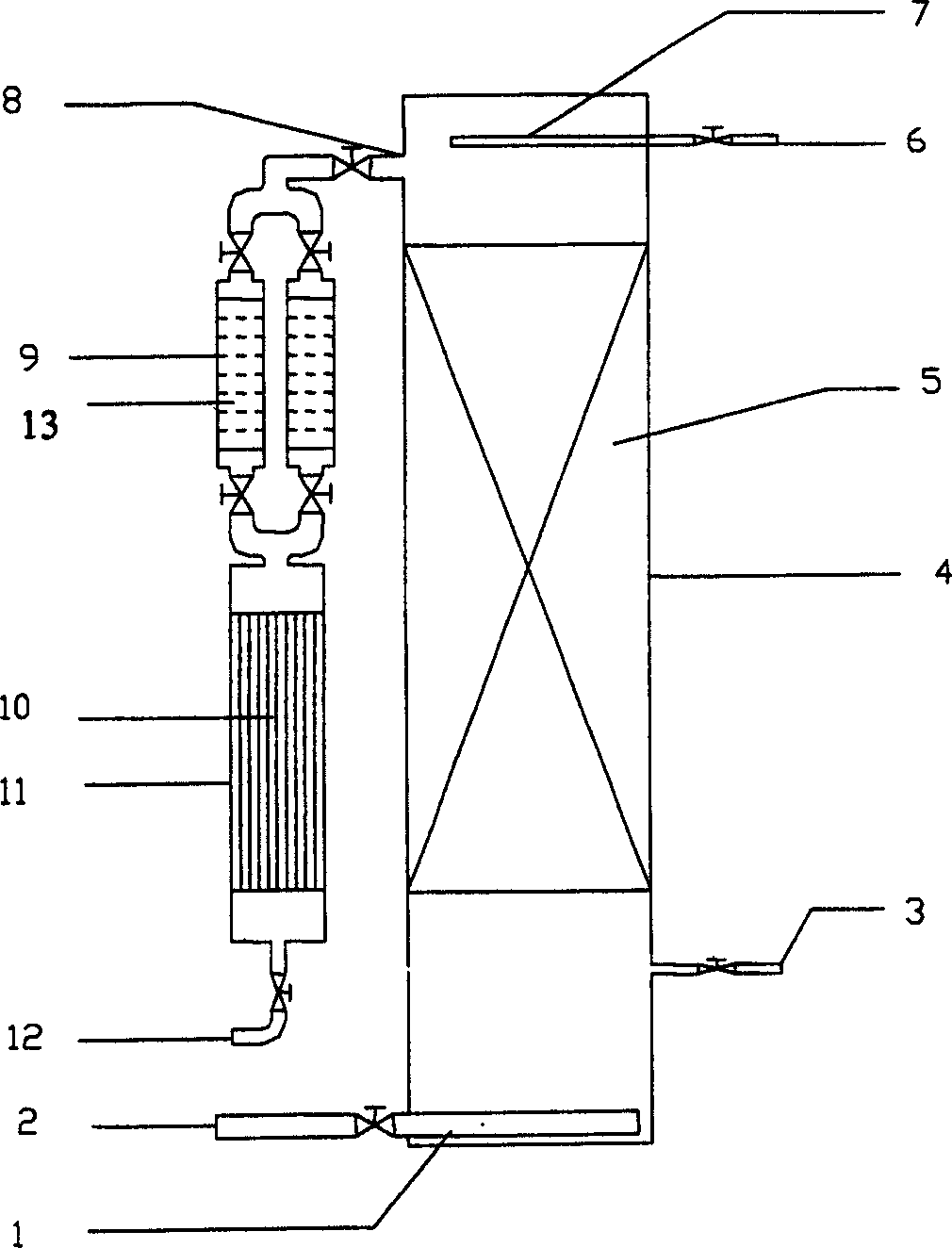

[0032] See figure 1 .

[0033] Catalytic oxidation-bioreactor exhaust gas treatment equipment made of plastic plates, its length, width and height are 50cm, 50cm, 1500cm respectively, including bioreactor 4 with packing, catalytic oxidizer 11, etc.; The bioreactor 4 of microorganism, the catalytic oxidizer 11 that oxidation catalyst 10 is housed and the drier 9 that desiccant 13 is housed constitute;

[0034] An air inlet 2 is opened on the lower side wall of the bioreactor 4, and a perforated pipe 1 is installed at the air inlet 2. The other side wall of the lower part is provided with a water outlet 3, the air inlet 2 should be lower than the water outlet 3, the upper side wall is provided with a spray liquid inlet 6, and there is a perforated pipe 7 at the inlet 6; the other side wall of the upper part is provided with an outlet Air pipe 8, air outlet pipe 8 are connected with drier 9.

[0035] The interior of the bioreactor 4 is filled with fillers 5 such as sponge or p...

Embodiment 2

[0045] See figure 1 .

[0046] The catalytic oxidation-bioreactor waste gas treatment equipment made of plexiglass has a diameter of 10 cm, and its structure and working process are the same as those in Example 1.

[0047] The treatment concentration is 511mg / m 3 The waste gas of acetic acid enters the catalytic oxidation-bioreactor from the air inlet 2, and the residence time is 1-3mins. Operate at room temperature. The concentration of gas outlet 12 is 1.06mg / m 3 , The removal rate reaches over 99.8%.

Embodiment 3

[0049] See figure 1 .

[0050] The catalytic oxidation-bioreactor waste gas treatment equipment made of plexiglass has a diameter of 10 cm, and its structure and working process are the same as those in Example 1.

[0051] The treatment concentration is 1306mg / m 3 The xylene waste gas enters the catalytic oxidation-bioreactor from the air inlet 2, and the residence time is 1-3mins. Operate at room temperature. The concentration of gas outlet 12 is 91.3mg / m 3 , which is lower than the maximum allowable concentration of harmful substances in the workshop air formulated by the state, and the removal rate reaches more than 93%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com