Method for preparing bisphenol A cyanate

A cyanate ester and bisphenol technology, which is applied in the field of organic polymer material synthesis, can solve problems such as environmental pollution, excessive product impurity content, complex post-processing, etc., and achieve the goal of ensuring high purity, reducing impurity content, and improving product purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

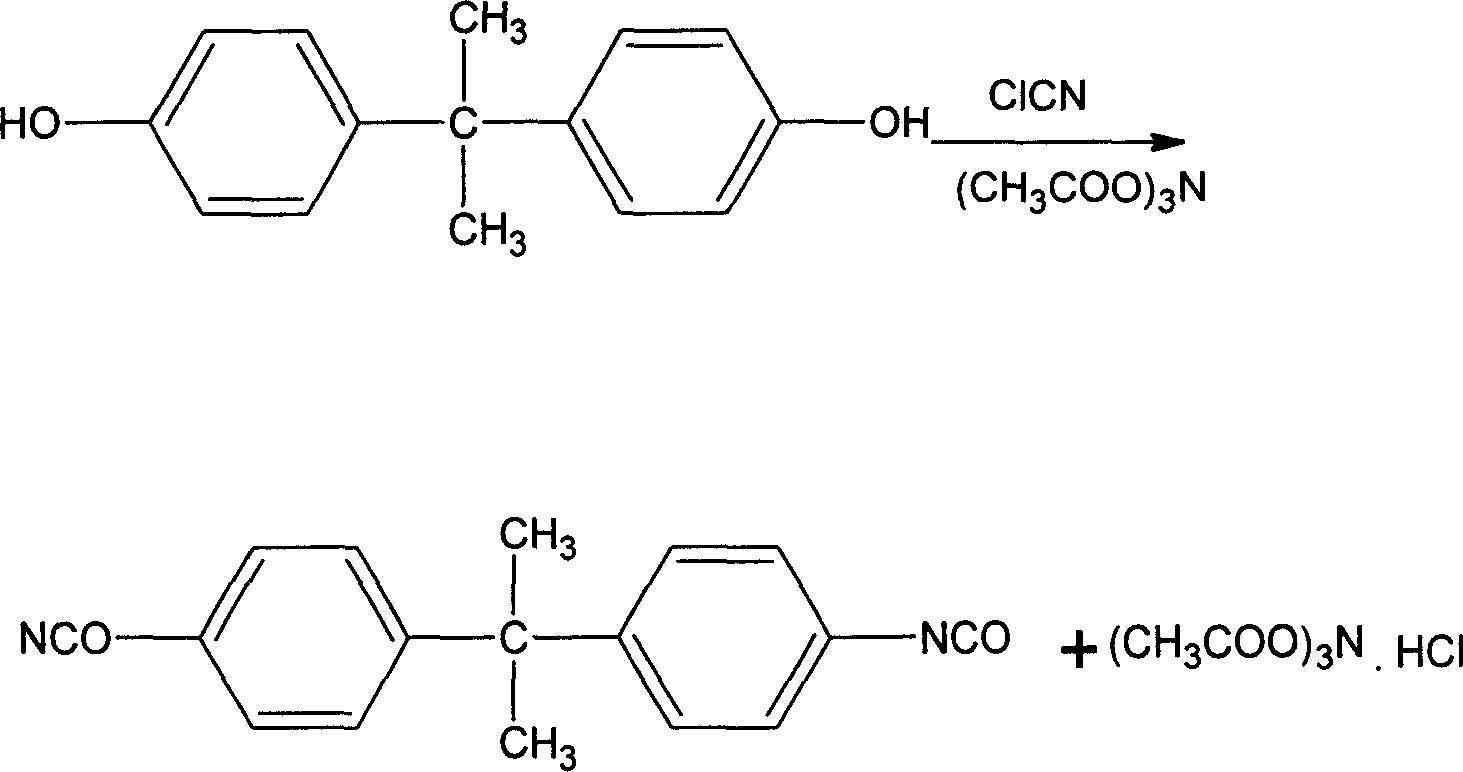

Image

Examples

Embodiment 1

[0037] A 1000ml four-necked flask equipped with a stirrer, a dropping funnel and a thermometer was first put into 200ml of acetone, cooled to -5°C, and then 61.5g (1.0mol) of cyanogen chloride was added.

[0038] 114g (0.5mol) of bisphenol A was dissolved in 250ml of acetone, 101g (1.0mol) of triethylamine was added to dissolve in 250ml of acetone, and 101g (1.0mol) of triethylamine was added and stirred uniformly.

[0039] The reaction temperature is controlled from -5°C to 0°C, and the above-mentioned mixed liquid is added dropwise to the acetone solution of cyanogen chloride for 2 hours. After the dropwise addition is completed, the reaction is completed after the temperature is kept for 30 minutes.

[0040] Under rapid stirring, the reaction solution was poured into ice water to make the reactant appear as white crystals, filtered, washed, and dried to obtain bisphenol A cyanate. The yield was 93%.

[0041] Appearance: white crystalline powder; content: 99.9% (HPLC method); mo...

Embodiment 2

[0043] As described in Example 1, add 500ml of isopropanol and add 68g (1.1mol) of cyanogen chloride after cooling. 114g (0.5mol) of bisphenol A, 105g (1.04mol) of triethylamine and 500ml of isopropanol, mix and dissolve, control for about 2 hours, add dropwise to cyanogen chloride solution, reaction temperature 3~6℃, and filter the reaction liquid , Wash, dry, and get the product. The yield was 89%.

[0044] Appearance: white crystalline powder; content: 99.8% (HPLC method); moisture: 0.05% melting moment: 77.5-80.2

Embodiment 3

[0046] As in the device described in implementation 1, first add 100 g of toluene, cool to below 10° C. and add 80 g (1.3 mol) of cyanogen chloride.

[0047] Bisphenol A 148.2g (0.65mol) triethylamine 131.3g (1.3mol) and toluene 250g are mixed uniformly. The mixed solution was added dropwise to the toluene solution of cyanogen chloride at a temperature below -5°C, and the dropping temperature was controlled at -5°C and the dropping time was 2 hours. After the addition is complete, keep the temperature at -5°C for 30 minutes, and the reaction is complete.

[0048] Add 200g of water to the reaction solution, separate with a separatory funnel after mixing, and continue to use 2×200g of water for the oil layer. After mixing and separating two times, the reactants are vacuum distilled to evaporate the toluene, and then add 15% isopropyl cooled to 5℃ The alcohol aqueous solution is rapidly stirred to crystallize the material, and filtered to obtain the target bisphenol A cyanate. The yi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com