Method for preparation of novel pipe type ceramic capacitor

A ceramic capacitor and tube-type technology, which is applied in the field of tube-type ceramic capacitor preparation, can solve the problem of low dielectric constant and achieve the effect of improving performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

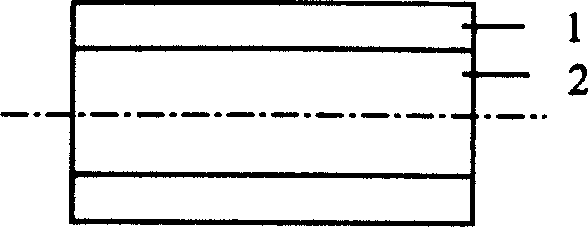

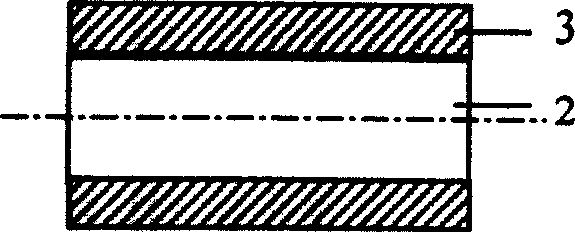

[0039] Example 1: Surface layer tubular ceramic capacitor

[0040] After adding 0.5wt% Nd 2 o 3 , 0.4wt% Bi 2 / 3 ZrO 3 and 0.1wt% MnO 2 High dielectric strength and high stability BaTiO 3 Semi-conductor ceramic material, the outer diameter φ is obtained by extrusion process 外 =2.4mm, inner diameter φ 内=1.8mm, length L=4mm porcelain tube, after the porcelain tube is sintered in the air at 1320°C, and then heat-treated in a reducing atmosphere at 1000°C-1100°C for 1-2 hours, a semi-conductor with a resistivity less than 2Ω·cm can be obtained. Conductive porcelain tube. The semiconductive porcelain tube is oxidized properly in the air at 900°C-1000°C, and the properties that can be obtained are: capacitance C>10000pF, dielectric loss tgδ1000MΩ, capacitance Temperature change rate ΔC / C(-25-+85℃)≤±15%, impact voltage V b ≥800v surface layer tubular ceramic capacitors.

example 2

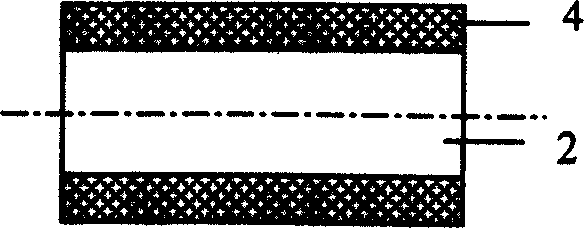

[0041] Example 2: Grain Boundary Layer Tubular Ceramic Capacitor

[0042] After adding 0.2wt% Ta 2 o 5 , 0.4 wt% SiO 2 and 0.1wt%Al 2 o 3 SrTiO 3 Porcelain material, the outer diameter φ is obtained by extrusion process 外 =2.4mm, inner diameter φ 内 =1.8mm, length L=4mm porcelain tube, the resistivity of the porcelain tube is about 0.5Ωcm after reduction and sintering at 1450°C, and the uniform coating composition on the surface of the semiconducting porcelain tube is 50wt%PbO+40wt%Bi 2 o 3 +5wt%Cu 2 O+15wt%B 2 o 3 After the mixed coating is heat treated in the air at 1200°C for 1-2 hours, the properties that can be obtained are: capacitance C>10000pF, dielectric loss tgδ1000MΩ, capacitance temperature change ΔC / C (-25~+85℃)≤±10%, breakdown voltage V b ≥300v grain boundary layer tubular ceramic capacitors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com