Separation and purification method for ginkgolide monomer

A ginkgolide, separation and purification technology, applied in organic chemistry, bulk chemical production and other directions, can solve the problems of single crystal form of monomer, differences in physical and chemical properties and efficacy, and achieve consistent crystal form, efficient production, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

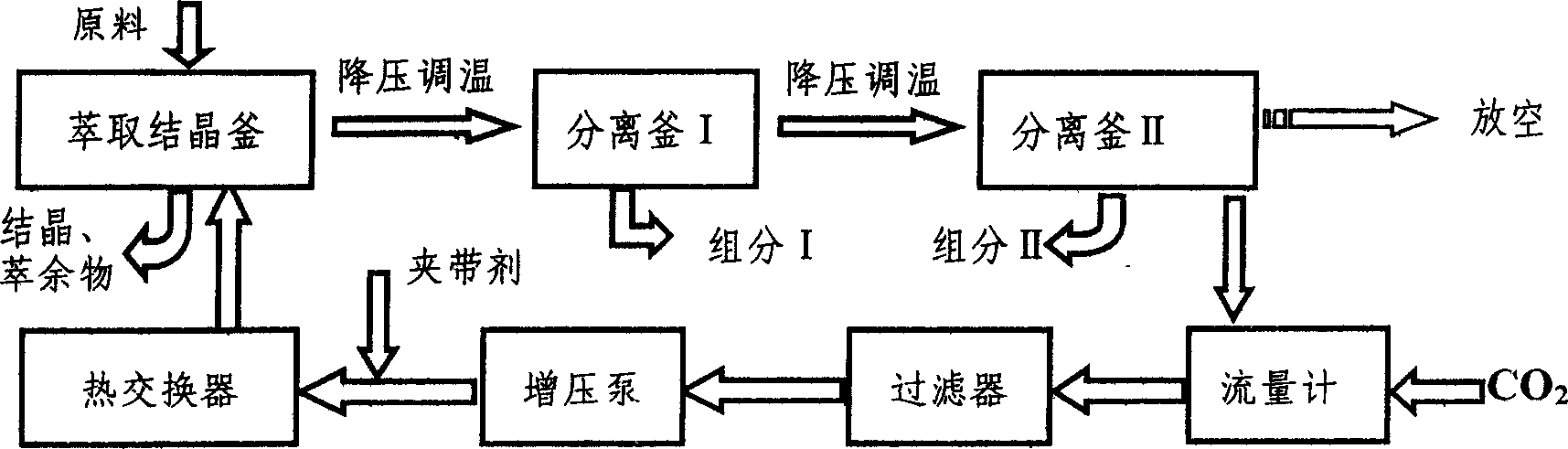

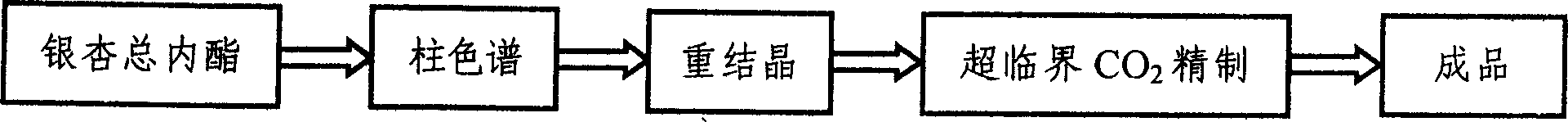

Embodiment 1

[0034] Take 100 g of total ginkgo lactones with a content ≥ 97%, dry them, add them to silica gel column chromatography, use petroleum ether-ethyl acetate mixed solvent as mobile phase (mixing ratio is 90:10~10:90), gradient elution, and collect Ginkgolide B (GB) fractions with a purity of ≥50%; vacuum concentrate the GB fractions to dryness to obtain crude GB; recrystallize with ethanol water; then use supercritical CO 2 Refining and purification (operating temperature 32-100°C, pressure 10-100MPa, extraction and crystallization) to remove trace impurities and solvents, and control the crystal form; drying; to obtain GB15-25g with a content greater than 99% (with the total ginkgo lactones in the raw material The content of GB is different, and the yield varies); the total yield is more than or equal to 90%.

Embodiment 2

[0036] Get 100g of total ginkgolides with a content ≥ 97%. Add it to silica gel column chromatography after drying, use petroleum ether-ethyl acetate mixed solvent as mobile phase (mixing ratio is 90:10~10:90), gradient elution, collect the ginkgolide A (GA ) fraction. The GA fraction was concentrated to dryness in vacuo to obtain crude GA. Recrystallize with ethanol-acetic acid-water, and then use supercritical CO 2 Refining and purification (operating temperature 32-150°C, pressure 10-100MPa) to remove trace impurities and solvents, and control the crystal form; drying; the highest content of 99.8% GA20-25g can be obtained (with GA in the total ginkgo lactone raw material The content is different, and the yield varies); the total yield is more than or equal to 85%.

Embodiment 3

[0038] Get 100g of total ginkgolides with a content ≥ 97%. After drying, add it to reverse-phase silica gel column chromatography, use methanol-water mixed solvent as mobile phase (mixing ratio is 95:5 ~ 5:95), gradient elution, and collect ginkgolide B (GB) with a purity of ≥50%. flow portion. The GB fraction was concentrated to dryness in vacuo to obtain crude GB. Recrystallization from methanol and water followed by supercritical CO 2 Refining and purification (operating temperature 32~150°C, pressure 10~100MPa), to remove trace impurities and solvents, and control the crystal form; dry; get GB25~35g with a content greater than 99% (with the content of GB in the total ginkgo lactone raw material Different, the yield varies); the total yield ≥ 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com