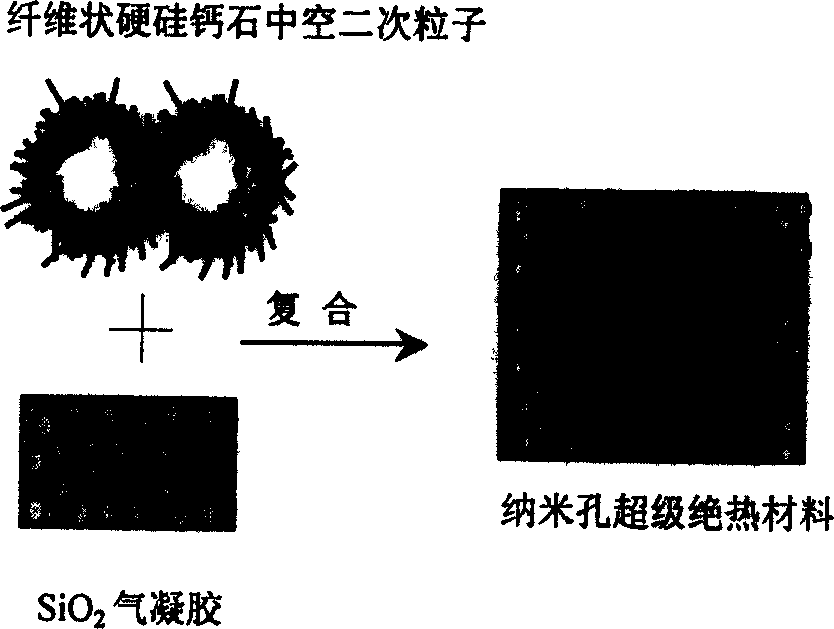

Prepn process of super heat insulating material of composite nanometer pore calcium silicate

A thermal insulation material and nanoporous technology, applied in ceramic products, applications, household appliances, etc., can solve the problems of low use temperature and large thermal conductivity, and achieve the effect of increasing strength and reducing thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] First prepare SiO according to the recipe 2 Sol. The specific formula is as follows: Tetrasilicon ethyl ester: ethanol: water = 1: 4.17: 0.28 (volume ratio), and then hydrochloric acid is added to make the pH 3. After stirring the configured airgel precursor for two hours, add water and stir again for about half an hour to prepare SiO 2 Sol.

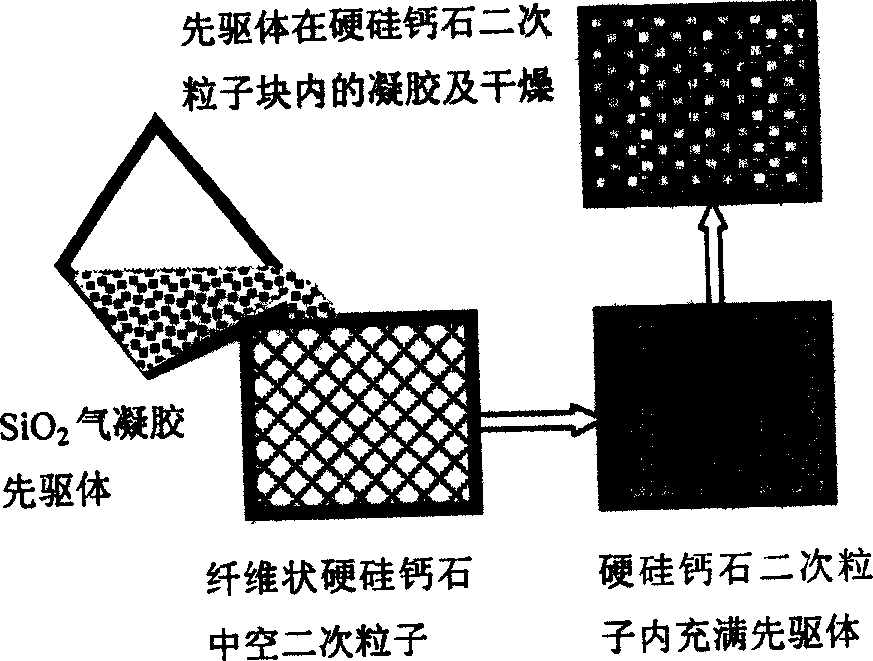

[0026] Put the formed xonotlite product with a hollow structure into a vacuum device, and carry out a vacuum treatment of 70Pa. The prepared SiO 2 The sol is sucked into the vacuum chamber and compounded with the vacuumed xonotlite product. Then close the vacuum valve immediately. After about half an hour, the vacuum valve is opened, and the floating xonotlite product sucks a large amount of SiO 2 The sol sinks below the liquid surface. After sealing the vacuum, let it stand to form a glue. After the sol is gelled, it is poured into an ethanol solution with a volume ratio of water:ethanol=1:4 for aging, and the poured etha...

Embodiment 2

[0028] Prepare SiO according to the recipe 2 Sol. Orthosilyl ethyl ester: ethanol: water = 1: 6: 0.20 (volume ratio). Hydrochloric acid was then added to bring the pH to 3. Stir the configured airgel precursor for 2.5 hours, then add water and stir again for about half an hour to prepare SiO 2 Sol.

[0029] The formed xonotlite product with a hollow structure is put into a vacuum device, and vacuumized to a vacuum degree of 70Pa. The prepared SiO 2 The sol is sucked into the vacuum chamber and compounded with the vacuumed xonotlite product. Then close the vacuum valve immediately. After about half an hour, the vacuum valve is opened, and the floating xonotlite product sucks a large amount of SiO 2 The sol sinks below the liquid surface. After sealing the vacuum, let it stand to form a glue. After the sol is gelled, it is poured into an ethanol solution with a volume ratio of water:ethanol=1:4 for aging, and the poured ethanol solution must exceed the liquid level of t...

Embodiment 3

[0031] The solution was prepared according to the formula of tetrasilyl ethyl ester:ethanol:water=1:7:0.28 (volume ratio), and then hydrochloric acid was added to make the pH 4. After stirring the configured airgel precursor for two hours, add water and stir again for about half an hour to prepare SiO 2 Sol.

[0032] Put the formed xonotlite product with a hollow structure into a vacuum device, and perform vacuum treatment at 100Pa. The prepared SiO 2 The sol is sucked into the vacuum chamber and compounded with the vacuumed xonotlite product. Then close the vacuum valve immediately. After about half an hour, the vacuum valve is opened, and the floating xonotlite product sucks a large amount of SiO 2 The sol sinks below the liquid surface. After sealing the vacuum, let it stand to form a glue. After the sol is gelled, it is poured into an ethanol solution with a volume ratio of water:ethanol=1:4 for aging, and the poured ethanol solution must exceed the liquid level of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com