Resin composition for light guide, solidified dry membrane , light guide and forming method thereof

A technology of optical waveguide and composition, which is applied in the field of optical waveguide, can solve the problems of dry film fracture or rupture, insufficient mechanical properties such as optical waveguide processability, bending property, and inability to obtain transmission characteristics, etc., and achieve low transmission loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

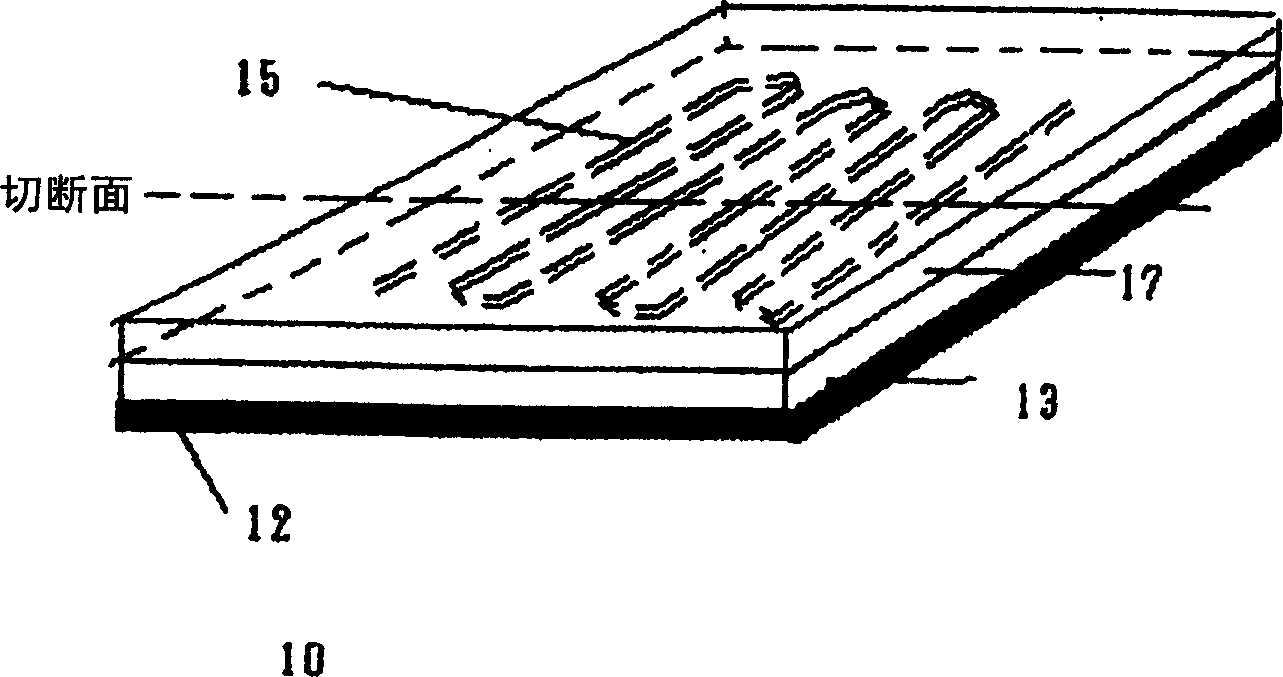

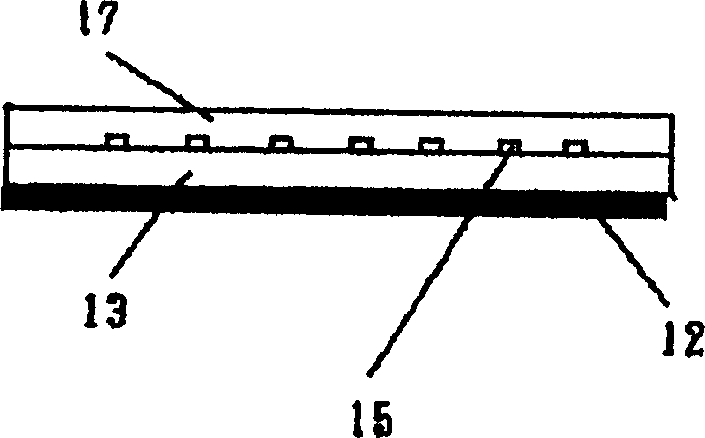

[0192] Formation of optical waveguides:

[0193] Formation of the lower cladding layer

[0194] The curable resin composition Z-2 for optical waveguides was coated on the surface of the silicon substrate by the spin coating method, and dried at 80° C. for 30 minutes. Then irradiate with a wavelength of 365nm and an illumination of 200mW / cm 2 After 5 seconds of ultraviolet rays, it was thermally cured at 150° C. for 30 minutes to obtain a lower cladding layer with a thickness of 40 μm.

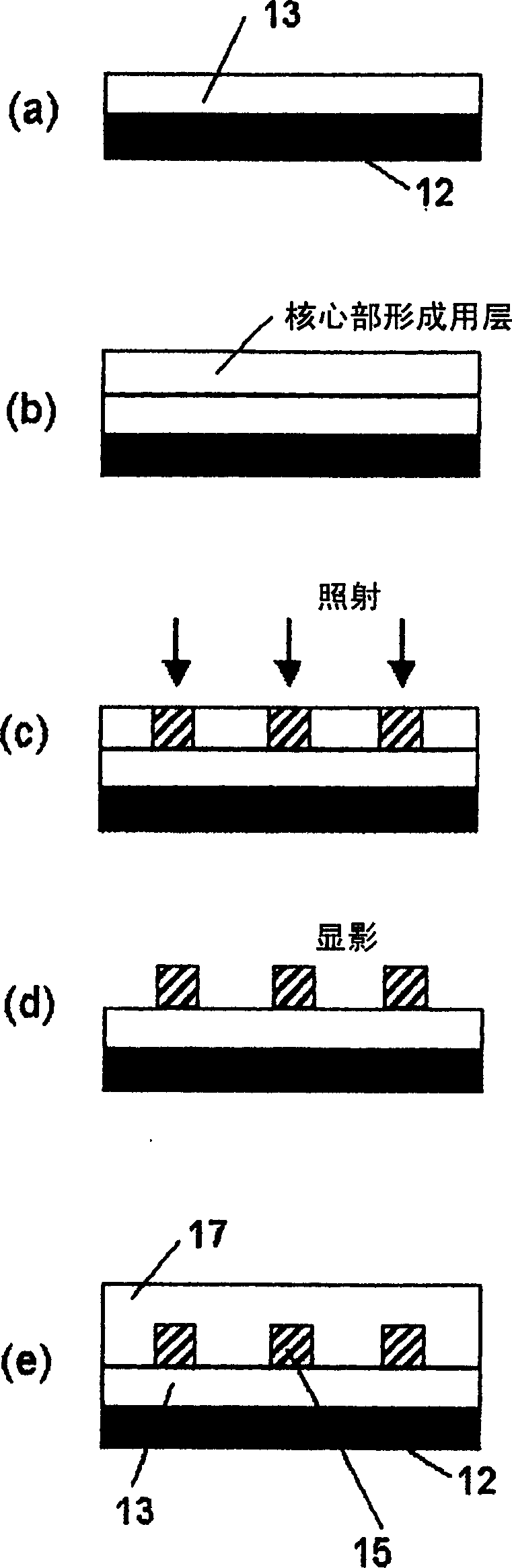

[0195] The formation of the core part (1):

[0196] Next, the curable resin composition Z-1 for an optical waveguide was applied on the upper surface of the lower cladding layer by a spin coating method, and dried at 80° C. for 30 minutes. Then pass through a photomask with a line pattern with a width of 30 μm, and irradiate with a wavelength of 365 nm and an illuminance of 10 mW / cm 2 UV light for 100 seconds to make it radiation cured. Next, the substrate having the resin composition laye...

Embodiment 1-2 and 1-3

[0209] Production and evaluation of dry film:

[0210] Resin compositions Z-1 to Z-2 for optical waveguides were coated on polyethylene terephthalate films (film thickness 25 μm) with a knife-edge applicator, and then dried at 80°C for 30 minutes to prepare optical waveguides. Resin composition dry film. Among them, "○" was used to form a dry film, and "X" was not used to form a dry film. In addition, the formed dry film was transferred onto a silicon substrate by an atmospheric pressure hot roll adhesion method (temperature 100° C.). The results that can be evenly transferred to the silicon substrate are indicated by "○", and those where the dry film part remains on the base film, or cannot be transferred to the silicon substrate, or cracks occur in the transferred film are indicated by "X". The results are shown in Table 3.

[0211] As a result of the above evaluation, in Examples 1-2 and 1-3, curable dry films for optical waveguides having film softening temperatures of ...

Embodiment 1-4

[0216] Formation and evaluation of dry film-based optical waveguides:

[0217] A curable dry film for an optical waveguide was prepared using the curable resin compositions Z-1 and Z-2 for an optical waveguide, and an optical waveguide was formed using the dry film.

[0218] Formation of the lower cladding layer:

[0219] The curable dry film ZD-2 for optical waveguide composed of curable resin composition Z-2 for optical waveguide was transferred to the surface of the silicon substrate by the normal pressure hot roll adhesion method (temperature 100°C), and then irradiated with a wavelength of 365nm , Illumination 200mW / cm 2 After 5 seconds of ultraviolet rays, it was thermally cured at 150° C. for 30 minutes to obtain a lower cladding layer with a thickness of 40 μm.

[0220] The formation of the core part (1):

[0221] Next, the curable dry film ZD-1 for optical waveguide composed of curable resin composition Z-1 for optical waveguide is transferred to the upper surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com