Process for preparing synthetic gas by reforming carbon dioxide-methane

A carbon dioxide and synthesis gas technology, applied in inorganic chemistry, chemical instruments and methods, non-metallic elements, etc., can solve problems such as energy waste and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

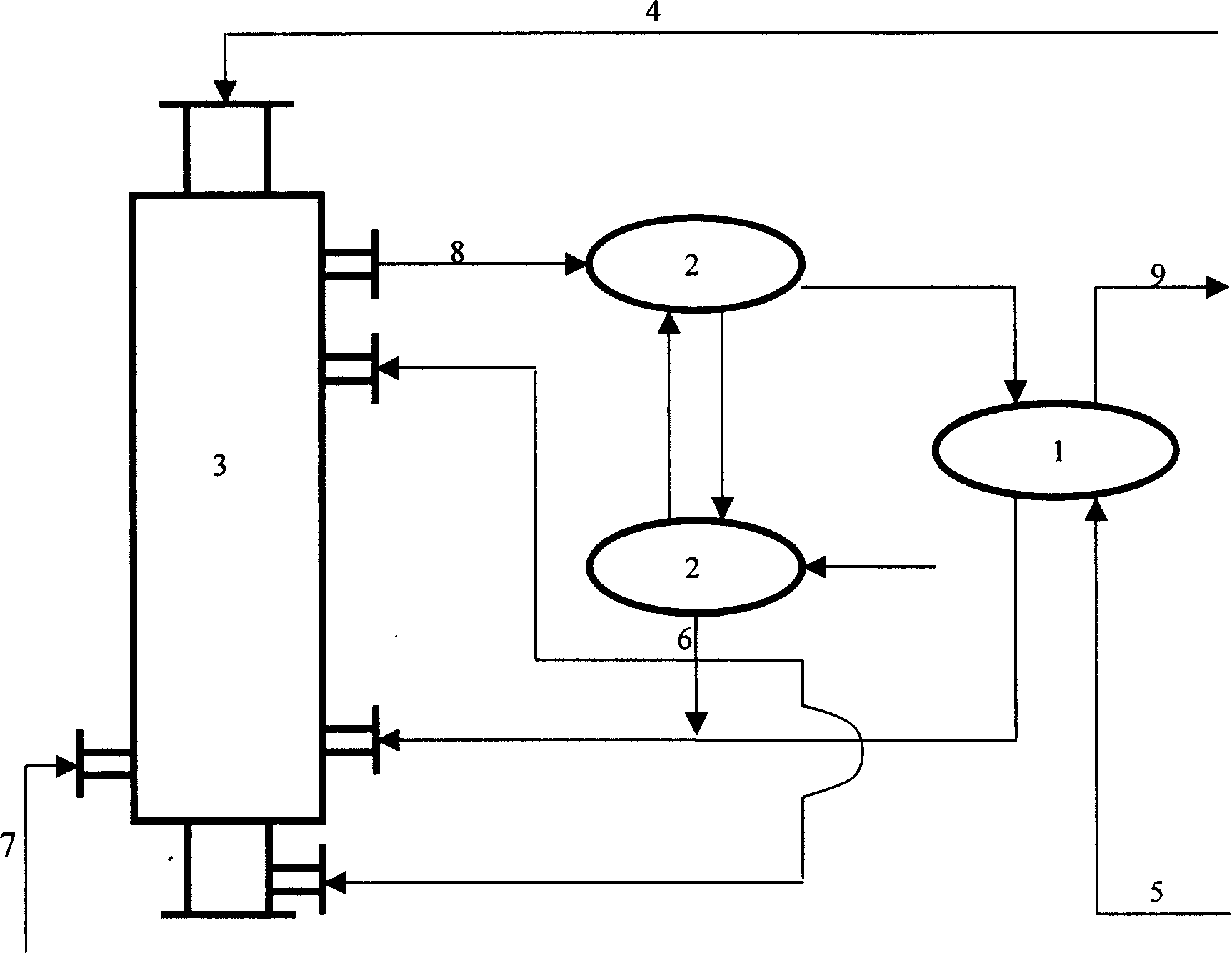

[0031] In this embodiment, iron alloy coke is used as the carbon material 4 . Weigh 8.0 g of the carbon material 4, and put it into the thermal conversion reactor 3 from the top of the fixed-bed thermal conversion reactor made of stainless steel. The bed height is 40cm, the porosity is about 50%, the thermal cracking temperature is 1080°C, and then the CH-rich 4 Gas and CO 2 The raw material gas 5 and the steam 6 from the waste heat boiler 2 mixed in before the thermal conversion reactor 3, (CH 4 :CO 2 : water vapor=1:1:1, flow rate 60.0ml / min), the oxygen 7 supplied from the bottom of the thermal conversion reactor 3 and part of the high-temperature charcoal or part of the combustibles rich in methane gas are burned to provide heat energy to make the heat conversion The temperature of reactor 3 rises to 950°C-1300°C. In thermal conversion reactor 3, high temperature C, H 2 O, O 2 and the H in the methane-enriched gas input to thermal reforming reactor 3 2 、CH 4 , and t...

Embodiment 2

[0036] According to the process of Example 1, metallurgical coke was used as the carbon material 4. Weigh 8.0 g of carbon material, put it into the moving bed thermal conversion reactor 3 made of stainless steel, the bed height is 40 cm, the porosity is about 50%, the thermal cracking temperature is 1080 ° C, and the gas CO 2 、CH 4 and water vapor, CH 4 :CO 2 :H 2 O=1:1:1, flow rate 30.0ml / min, the reaction result is as follows:

[0037] h 2 54.60%, CO 42.90%, CH 4 0.47%, CO 2 2.00%

Embodiment 3

[0039] According to the process of Example 1, anthracite (4% volatile matter) was used as the carbon material 4 . Weigh 8.0 g of carbon material, put it into the fluidized bed thermal conversion reactor 3 made of stainless steel, the bed height is 40 cm, the porosity is about 50%, the thermal cracking temperature is 1080 ° C, and the gas CO 2 、CH 4 and water vapor, CH 4 :CO 2 :H 2 O=1:1:1, flow rate 15.0ml / min, the reaction result is as follows:

[0040] h 2 59.50.00%, CO 38.80%, CH 4 1.20%, CO 2 0.50%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com