Method for improving Ag base composite transparent conductive film stability

A transparent conductive film, stability technology, applied in optical components, optics, instruments, etc., can solve problems such as poor stability, achieve the effect of improving thermal stability, improving film quality, and reducing the tendency of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

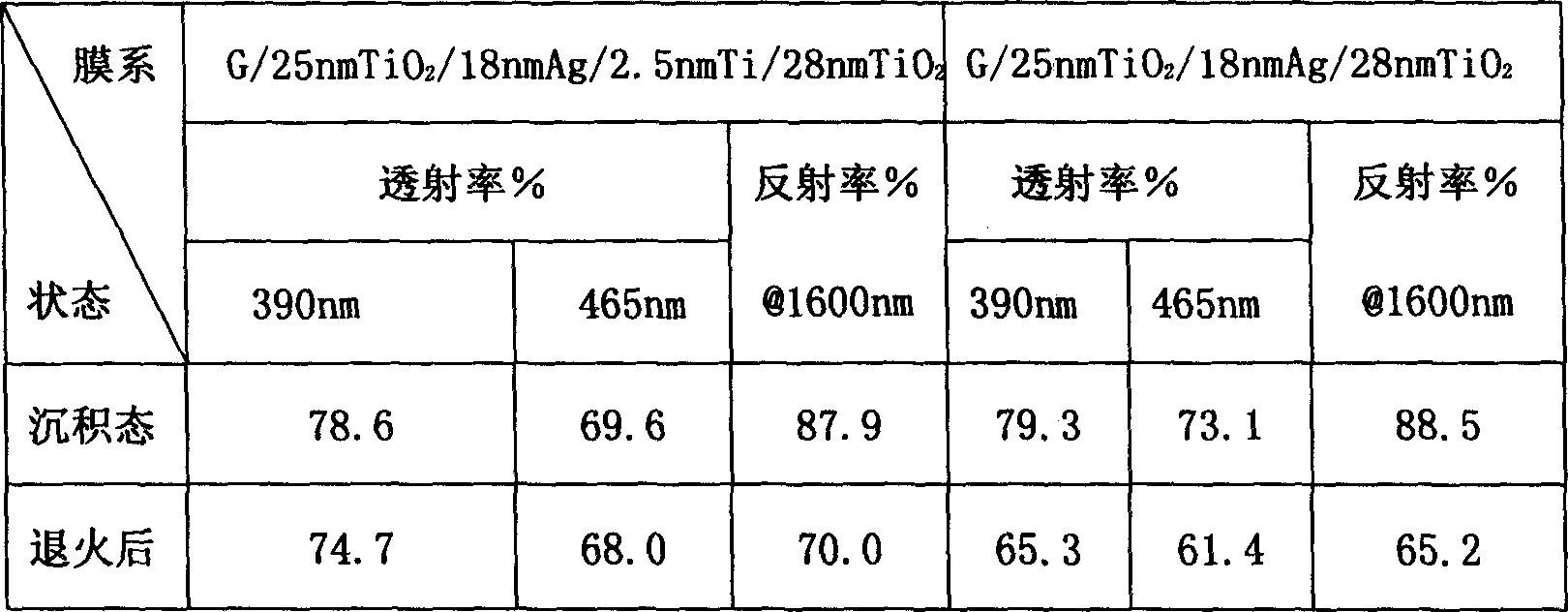

[0012] G / 25nmTiO 2 / 18nmAg / 2.5nmTi / 28nmTiO 2 with G / 25nmTiO 2 / 18nmAg / 28nmTiO 2 Compared

[0013] The multilayer film preparation process conditions are as follows: the substrate is a polished quartz crystal slice 40mm×20mm×1mm and a Si(111) sheet. Chemical and ultrasonic cleaning. The substrate temperature was 45°C. Vacuum degree: the background vacuum is 1×10-2Pa, after bombarding the substrate with ion beam for 15min, the vacuum is then pumped to 3.5×10-3Pa. Raw material and heating source: Ag: particles with a purity of 99.9%, heated by molybdenum boat resistance wire; TiO 2 : The purity is 99.9% particles, water-cooled crucible electron gun heating. The deposition rate is 0.3nm / s; Ti: particles with a purity of 99.9%, heated by an electron gun in a water-cooled crucible. The deposition rate was 0.3 nm / s. At the same time, the film layer adopts a heat treatment process of 537K×40min, and the treatment atmosphere is air.

[0014] After adding 2.5nmTi transition la...

Embodiment 2

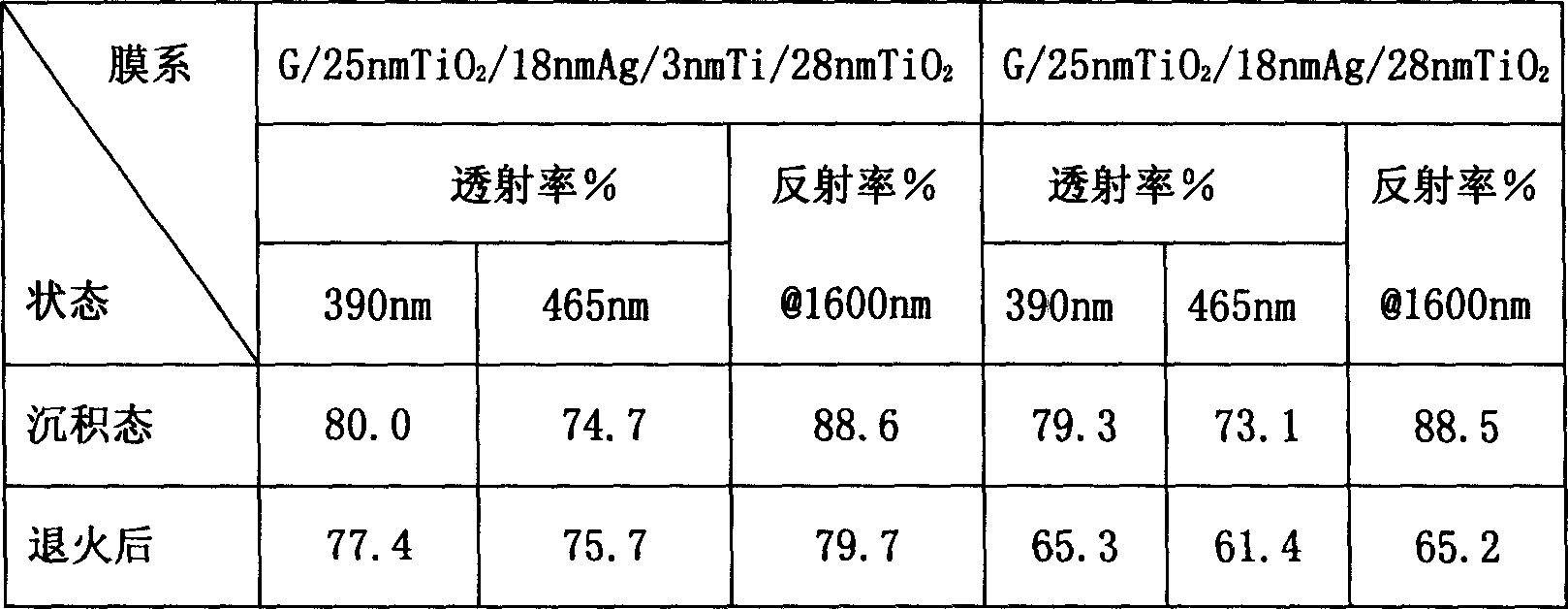

[0018] G / 25nmTiO 2 / 18nmAg / 3nmTi / 28nmTiO 2 with G / 25nmTiO 2 / 18nmAg / 28nmTiO 2 Contrasting multilayer film preparation process conditions are the same as embodiment 1, and its thermal stability performance comparison index is shown in the following table:

[0019] After adding 3.0nmTi transition layer, thermal stability performance comparison index:

[0020]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com