Raster polarization photomask plate and its application in projection photoetching system

A grating polarization and mask technology, which is used in polarizing elements, microlithography exposure equipment, and originals for opto-mechanical processing, etc., can solve the problem of shortened exposure wavelength, high manufacturing cost, and difficulty in phase shifter design and placement. and other problems, to achieve the effect of improving lithography resolution, reducing proximity effect, and improving resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

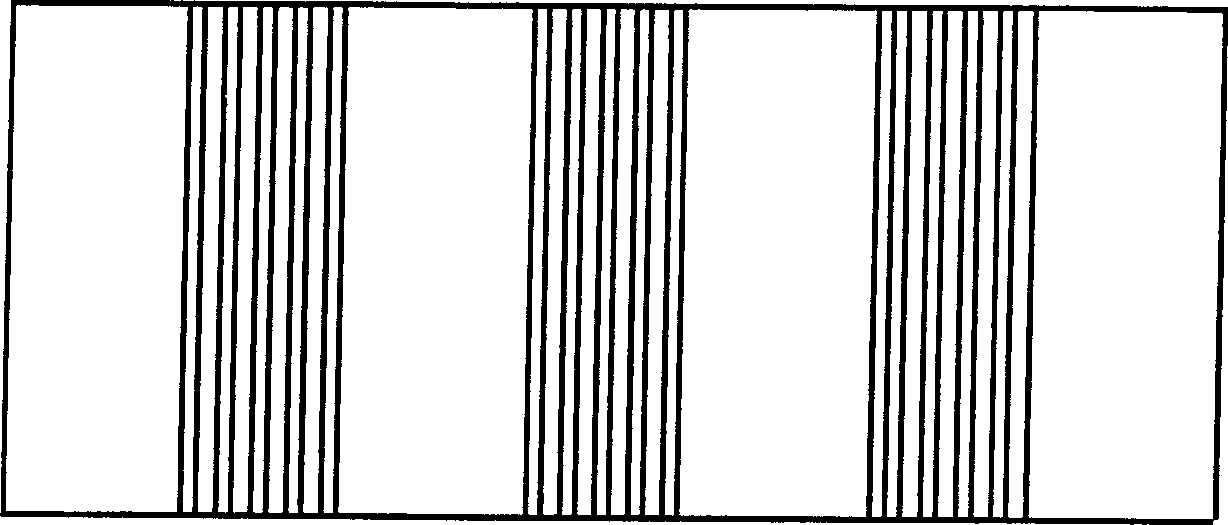

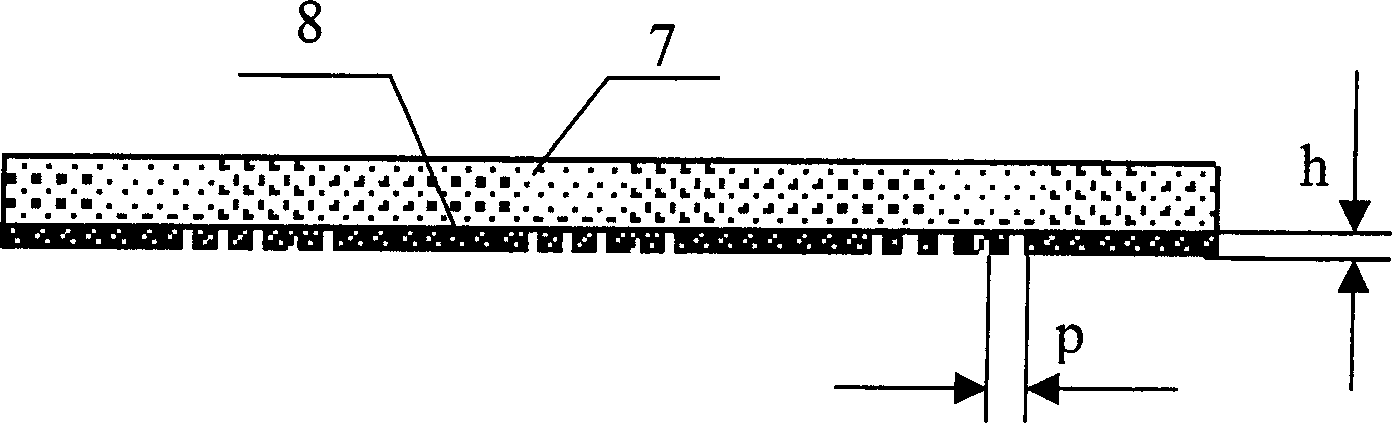

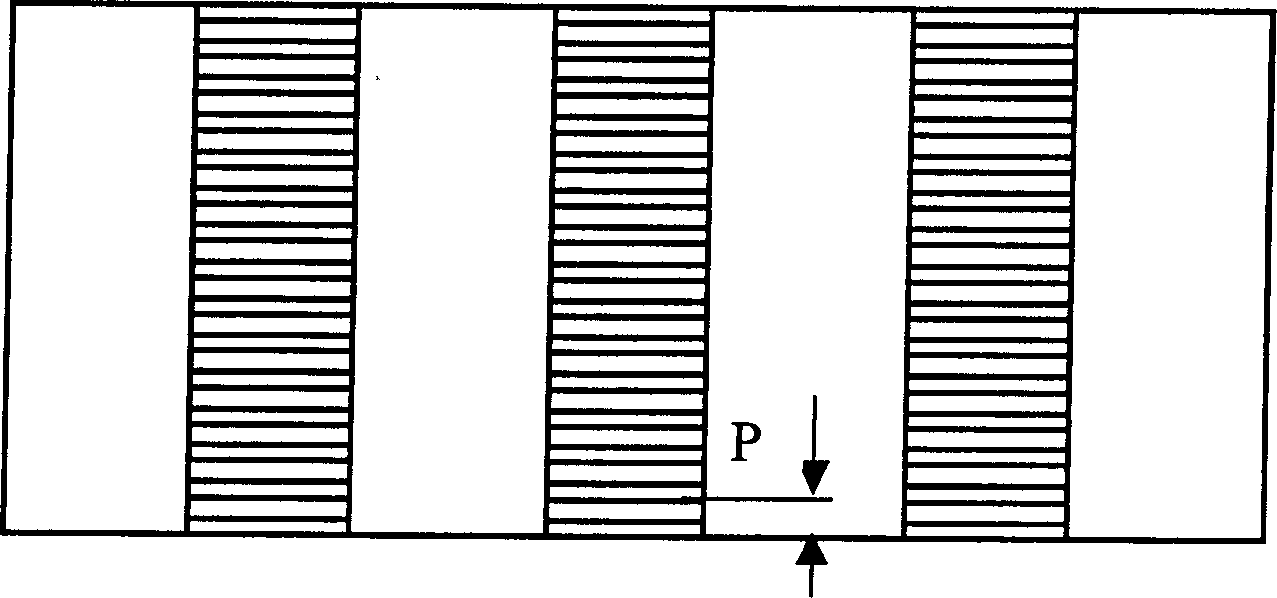

[0018] Such as figure 1 , 2 Shown is embodiment 1 of the present invention, on the quartz substrate 7 covered with one layer of opaque metal film 8, metal film is chromium, molybdenum etc., the thickness h of metal film is (0.25~0.85)P, wherein P is The grating period of the grating polarization structure. The metal film 8 is etched with a line feature pattern that needs photolithography. According to the line feature pattern on the mask, a grating polarization structure is etched in the mask line feature pattern. The grating period p of the grating polarization structure is (0.25~ 0.5) λ, where λ is the exposure wavelength of the projection optical lithography system; the grating period P is specifically determined as mλ / (n±sinθ), where m is the diffraction order of the diffracted beam, and λ is the exposure wavelength of the projection optical lithography system , n is the refractive index of the metal film described, θ is the incident angle. The etching depth h of the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com