Magnetic levitation switch reluctance motor radial neural network reversed decoupling controller and method for constructing same

A neural network inverse and decoupling controller technology, applied in the field of electric drive control equipment, can solve problems such as increased rotor frictional resistance, uneven motor air gap, and poor motor dynamic characteristics, achieving broad application prospects and getting rid of dependence. , the effect of high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

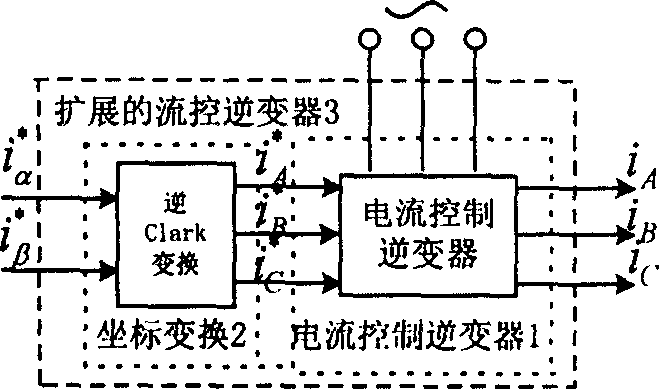

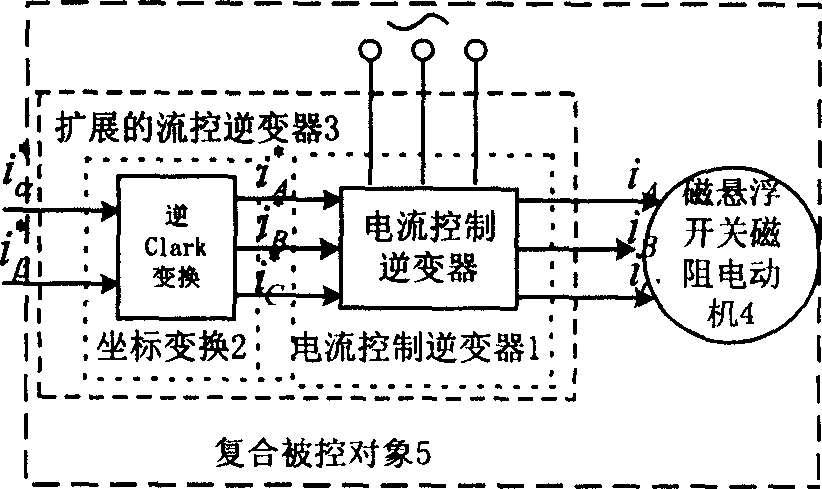

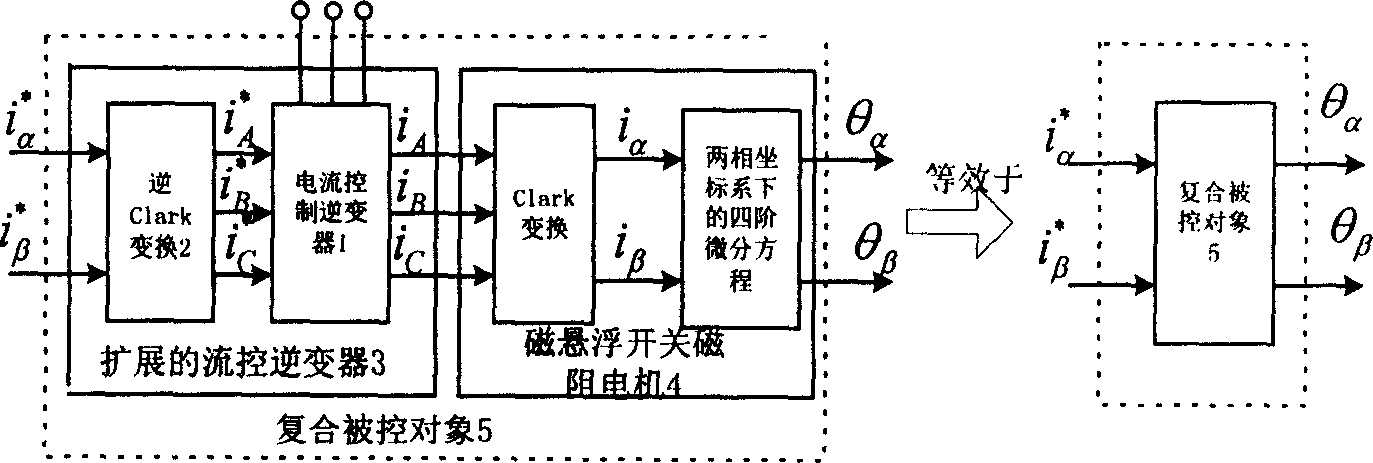

[0023] The implementation of the present invention is: firstly, the current hysteresis control voltage source inverter and Clark transformation jointly form an extended current control inverter, and this extended current control inverter will serve as the entire neural network inverse decoupling controller A part of. Secondly, the extended flow control inverter and the magnetic levitation switched reluctance motor suspension position control are taken as a composite controlled object, which is equivalent to a fourth-order differential equation model in a two-phase coordinate system, and the relative order of the vector of the system Is {2, 2}. A static neural network with 6 input nodes and 2 output nodes (static neural network is a multi-layer network MLN) plus 4 integrators (s -1 ) To construct the neural network inverse of the compound controlled object. And by adjusting each weight coefficient of the static neural network, the neural network inversely realizes the inverse syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com