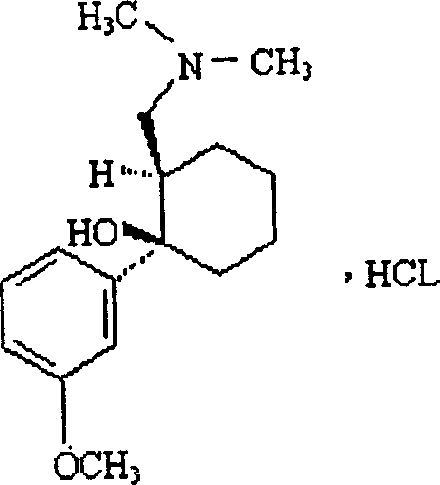

Oral disintegration tablet of tramadol hydrochloride and preparation method

A technology of tramadol hydrochloride and orally disintegrating tablets, applied in the field of tramadol hydrochloride orally disintegrating tablets and its preparation, can solve problems such as accidents, failure to achieve rapid onset of effect, and inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The present invention is prepared by adopting the following proportioning formula.

[0022] Tramadol hydrochloride 5%, polyethylene glycol 6000 (PEG6000) 35%, starch 48%, low-substituted hydroxypropyl cellulose (L-HPC) 8%, stevioside 3.5%, magnesium stearate 0.5%. The above raw materials are all available in the market and easy to buy.

[0023] The preparation method is as follows: Weigh each component according to the prescribed amount in the above formula. First, heat and melt the weighed polyethylene glycol 600087.5 mg, add 12.5 mg of tramadol hydrochloride powder that has been crushed through a 100-mesh sieve in advance, stir uniformly, and then quench the melt to solidify at low temperature, crush and sieve. Add 120 mg of starch, 20 mg of low-substituted hydroxypropyl cellulose, 8.75 mg of stevioside, wet granulation, and 1.25 mg of magnesium stearate for tableting. The disintegration time limit is 18 minutes, and the taste is relatively bitter.

Embodiment 2

[0025] The present invention is prepared by adopting the following proportioning formula.

[0026] Tramadol hydrochloride 10%, polyethylene glycol 4000 (PEG4000) 27.8%, starch 45%, low-substituted hydroxypropyl cellulose (L-HPC) 8.7%, stevioside 8%, and magnesium stearate 0.5%. The above-mentioned raw materials are all sold and easily purchased in the market.

[0027] The preparation method is as follows: Weigh each component according to the prescribed amount in the above formula. First, heat and melt the weighed polyethylene glycol 400069.5 mg, add 25 mg of tramadol hydrochloride powder that has been crushed through a 100-mesh sieve in advance, and stir evenly, then quench the melt to solidify at low temperature, crush and sieve. Add 112.5 mg of starch, 21.75 mg of low-substituted hydroxypropyl cellulose, 20 mg of stevioside, wet granulation, and 1.25 mg of magnesium stearate for tableting. The disintegration time limit is 16 minutes, and the taste is bitter.

Embodiment 3

[0029] The present invention is prepared by adopting the following proportioning formula.

[0030] Tramadol hydrochloride 15%, polyethylene glycol 4000 (PEG4000) 38.8%, polyethylene glycol 6000 (PEG6000) 13.9%, microcrystalline cellulose (MCC PH102) 12%, low-substituted hydroxypropyl cellulose (L- HPC) 8%, stevioside 12%, talc 0.3%. The above-mentioned raw materials are all sold and easily purchased in the market.

[0031] The preparation method is as follows: Weigh each component according to the prescribed amount in the above formula. First, the polyethylene glycol 4000 97mg and the polyethylene glycol 6000 34.75mg are heated and melted, and 37.5mg of tramadol hydrochloride powder that has been crushed through a 100-mesh sieve in advance is added, and the mixture is stirred evenly, and then the melt is quenched and solidified at low temperature. Crush and sieve. Add 30 mg of microcrystalline cellulose (MCCpH102), 20 mg of low-substituted hydroxypropyl cellulose, 30 mg of stevios...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com